A US fertilizer plant was experiencing recurring reliability problems with its horizontal multistage boiler feed pumps. The series of repeat failures motivated the owner plant to consult with a widely-known unbiased aftermarket pump service provider. Previous experience with this company’s Texas facility gave the plant confidence that they had the capability to troubleshoot the problem and provide a solution. This type of supplier has been classified as a “CPRS”— Competent Pump Repair Shop, because their worldwide affiliates are staffed by specialists who have the fullest support of pump engineers at the company headquarters.

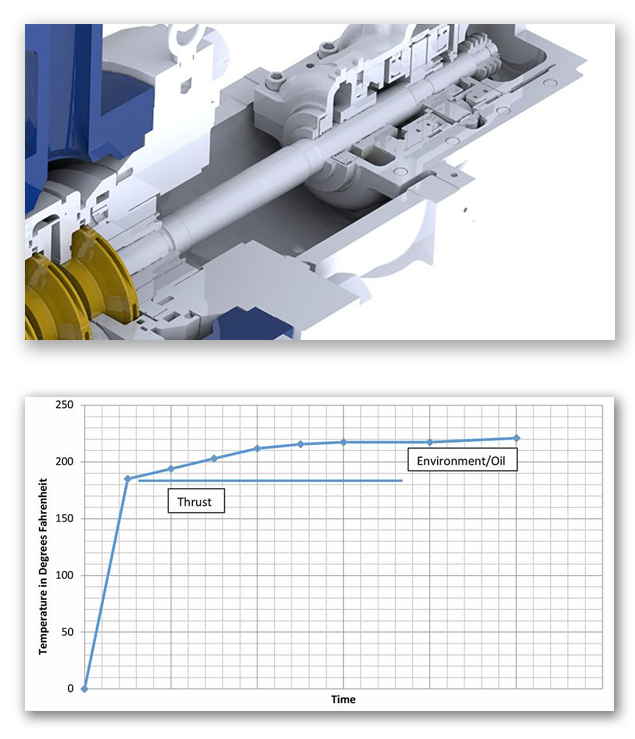

The aftermarket pump service provider performed a failure modes and effects analysis (FMEA) that took into consideration historical failure information and included an independent engineering analysis of the operating conditions. A review of the system history uncovered that the fertilizer plant had originally been designed with two 100% pumps. When the system was uprated, increased output requirements necessitated that both pumps operate in parallel to meet the new demand. Based on this information, the FMEA determined that the most probable failure mechanism was discharge recirculation caused by low flow operation.