For Release 8:00 AM

Wednesday, December 27, 2023

Hydro Parts Solutions Announces New Purpose-Built Facility

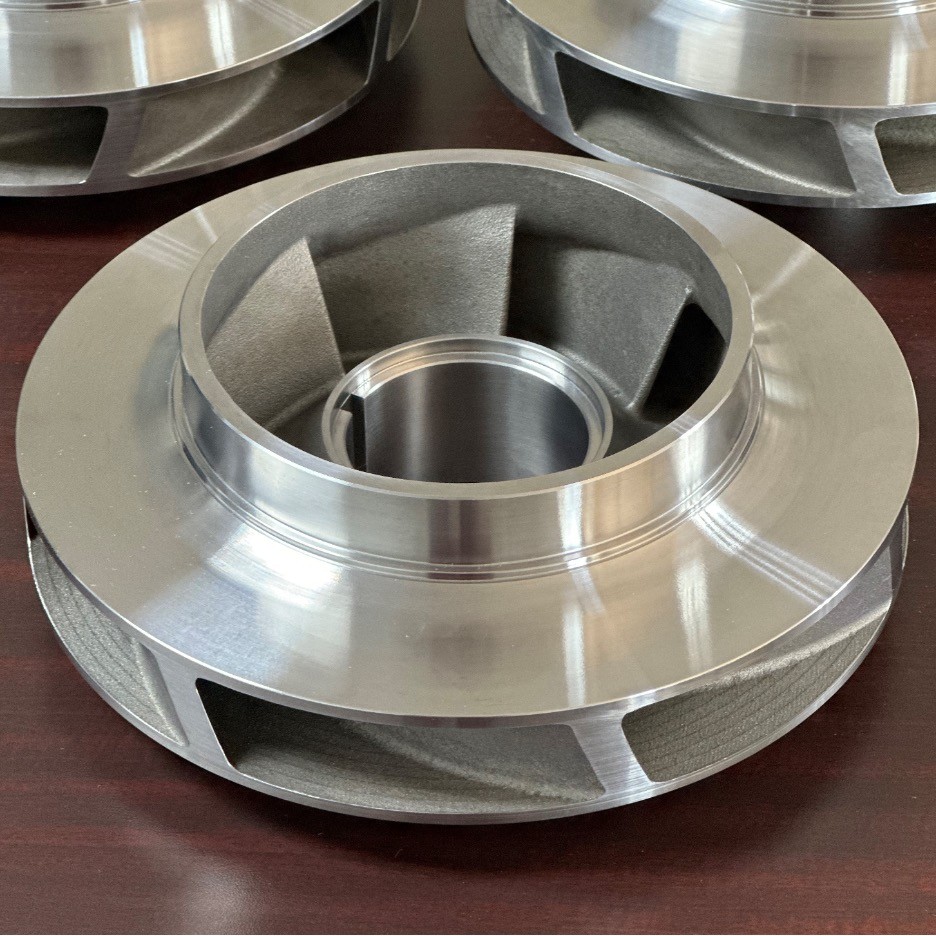

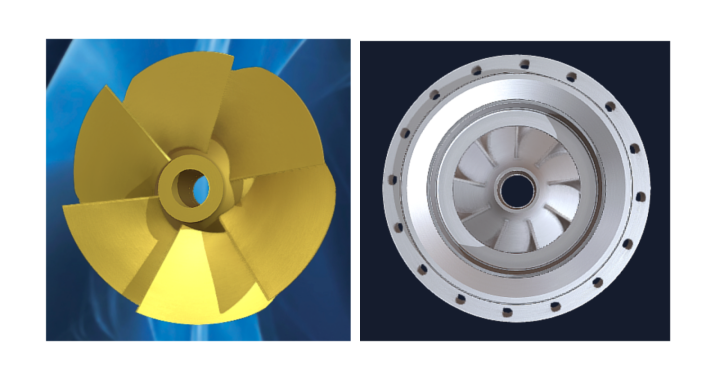

Hydro’s newest expansion in Texas is a purpose-built facility with reverse engineering capabilities and greater ability to provide both cast and machined parts.

Nederland, TX. — Wednesday, December 27, 2023 — Hydro Parts Solutions (HPS), a subsidiary of Hydro, Inc., opened the doors of its new Nederland facility in June 2023. HPS announced immediate availability to support customers with emergency part solutions. Using their extensive experience in reverse engineering and casting technology, HPS manufactures high quality parts, including difficult-to-source or obsolete components. The combination of in-house expertise and partnerships with local foundries allows them to provide industry-leading lead times, maintain strict quality control, and produce all parts in the USA.

Embracing technology at every step, HPS offers casting simulations, CNC aluminum, investment, and 3D printed patterns, bleeding edge reverse engineering techniques, and a post-machining equivalency analysis. This commitment to advanced technology, stringent tolerances, and rigorous process documentation ensures that the parts they provide customers with are accurate and consistent.

“Being conveniently located so close to the Golden Triangle, we have a great advantage with local partnerships and proximity to materials,” said Travis Puente, Operations Manager at HPS, “and the foundries we’ve partnered with, we’ve thoroughly qualified for quality and efficiency.”

###

For more information, press only:

PR Contact Name: Laura Oppermann

Email: loppermann@hydroinc.com

Website: https://hydroinc.com/parts-solutions/

Hydro is excited to announce that our very own Ares Panagoulias has been chosen by Pumps and Systems Magazine as one of “2021’s 10 Pump Professionals to Watch”. This annual list is compiled and curated by the editors and the editorial board of Pumps and Systems Magazine, the premier industry publication for the North American Pump Industry. The list recognizes some of the best and the brightest in the pump industry.

Hydro is excited to announce that our very own Ares Panagoulias has been chosen by Pumps and Systems Magazine as one of “2021’s 10 Pump Professionals to Watch”. This annual list is compiled and curated by the editors and the editorial board of Pumps and Systems Magazine, the premier industry publication for the North American Pump Industry. The list recognizes some of the best and the brightest in the pump industry. An Eye Toward the Future

An Eye Toward the Future

Hydro is proud to announce the inauguration of the Centaur Monitoring and Diagnostic Center at the HydroAire Service 40th Street location in Chicago, Illinois, USA. The M&D Center supports end-users who monitor their critical equipment through

Hydro is proud to announce the inauguration of the Centaur Monitoring and Diagnostic Center at the HydroAire Service 40th Street location in Chicago, Illinois, USA. The M&D Center supports end-users who monitor their critical equipment through

This agreement authorizes Damus to actively market, develop and pursue, inter-alia, engineered pump solution opportunities which will not only benefit Hydro and Damus but the various sectors of the economies of Trinidad and Tobago, as well as the wider Caribbean region. Whilst Damus is traditionally known in the fabricating and stationary mechanical equipment maintenance space, we see this partnership as a strategic initiative to increase our value proposition to our customers.

This agreement authorizes Damus to actively market, develop and pursue, inter-alia, engineered pump solution opportunities which will not only benefit Hydro and Damus but the various sectors of the economies of Trinidad and Tobago, as well as the wider Caribbean region. Whilst Damus is traditionally known in the fabricating and stationary mechanical equipment maintenance space, we see this partnership as a strategic initiative to increase our value proposition to our customers.