Case Studies

Fertilizer Focus: Resolving Design Flaws in UAN Solution Pump

Heavy Wear of the Bushing Bore

A newly commissioned US fertilizer plant was experiencing recurring vibration problems with their vertical UAN Solution pump. The VSF vertically suspended pump was removed from service and sent to Hydro for a full inspection and investigation of the vibration source. When the pump was disassembled, it was evident that there were significant problems at the motor bearing and guide bushing locations. These design flaws that were affecting reliable operation of the pump. Continue reading

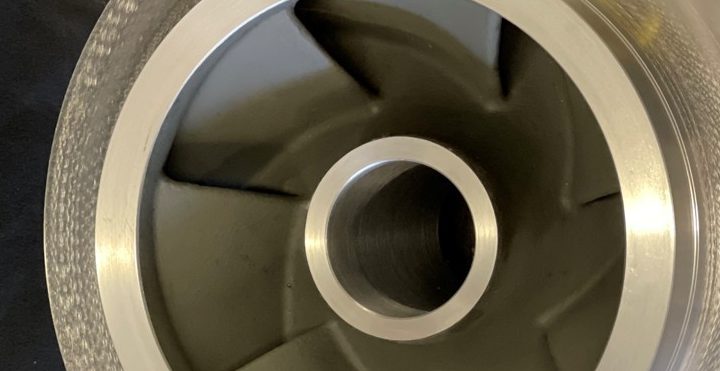

State of the Art Parts: Double Suction Impeller

Hydro Parts Solutions recently provided a double suction impeller for a Gulf Coast refining and petrochemical site. As is standard with Hydro’s cast parts, this complex component was:

- Scanned

- Reverse engineered

- Reviewed by Hydro’s engineering team

- Cast

- Final machined

- Compared to the original model

Reverse Engineering – An End to Obsolescence

A nuclear utility had a large circulating water pump with severe vibration issues that required refurbishment in an emergency time frame. Hydro’s Aston, PA service center, which has a 50-ton crane and a history of providing quality repair for nuclear non-safety related equipment, was chosen for this work. Despite the unique challenges in machining and maneuverability presented by large pumps, the DCI and refurbishment were performed in under 2 weeks. Continue reading

Fully Equipped & On the Move