As new design and manufacturing technologies are developed, end users can affordably upgrade their systems and verify better performance.

Written by: Bob Jennings & Dr. Gary Dyson (Hydro, Inc.)

Publisher: Pumps & Systems / August 2015

The rising cost of electrical power has caused many industrial plants to shift their focus to energy consumption. Plants often run pumping equipment continuously, and much research has pointed to opportunities for cost savings by optimizing pumping equipment.

When evaluating the potential for energy savings, end users cannot consider a pump in isolation. The suitability of the pump for the system within which it operates is vital. Even the best designed and most efficient equipment offers power-saving potential if it is run off its best efficiency point (BEP) in a system for which it is ill-applied.

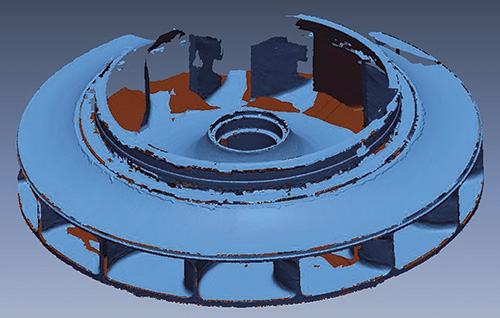

Image 1. Much research has pointed to opportunities for cost savings by optimizing pumping equipment. (Images and graphics courtesy of Hydro, Inc.)

Many plants have been in operation for more than 40 years, and their operating philosophies have changed over time. Plant improvements have enabled higher throughput, often increasing production by as much as 125-150 percent. Unfortunately, little is done to improve or increase the performance of the support-service pumping equipment, such as cooling water pumps.

As system flow demands increase, the duty point of the pumps is forced to shift far to the right of the BEP, well outside the acceptable operating range (AOR). This causes efficiency and pump reliability to decrease dramatically.

Casting tolerances, surface finishes, and impeller/volute or impeller/diffuser geometry have all dramatically improved during the last 40 years. But because many pumps were installed when the plants were commissioned, the existing pumps were manufactured using techniques that would be considered obsolete today. The result is higher energy costs and reduced reliability and availability, which often cause production delays. Continue reading

We are very pleased to announce that Hydro’s Test Lab is the first test lab to be certified by the Hydraulic Institute in their

We are very pleased to announce that Hydro’s Test Lab is the first test lab to be certified by the Hydraulic Institute in their