Written by: Bill Rademacher and Jarrod Streets, BP, Jeff Johnson and William Gottschalk, Hydro Inc.

Publisher: Pumps & Systems / August, 2012

Photo provided by BP of four IR 24 HV bottom-suction pumps and one IR 24 FV pump (P-15) in BP Whiting Refinery’s water station on Lake Michigan

Positioned on the shores of Lake Michigan are two stations that contain cooling water pumps which feed cooling water to BP’s Whiting Refinery. The #1 water station contains four IR 24 HV pumps, which are large, single-stage, double-suction, horizontal split case pumps. Four pumps in station #1 (P-11, P-12, P-13, and P-14 in the photo below) are unique in that they were designed with a bottom-suction configuration.

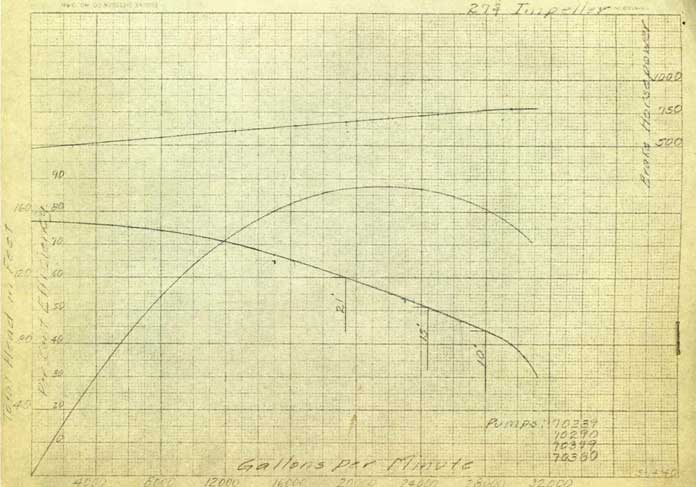

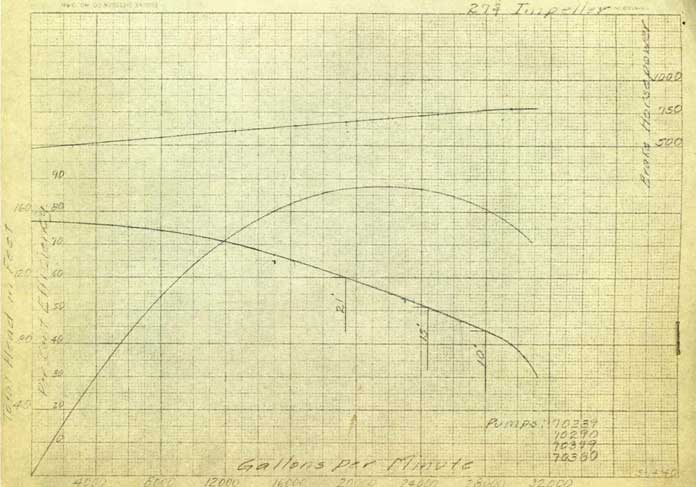

Photo provided by BP of Cameron performance curve circa 1933

The rotating equipment engineers at the refinery wanted to better understand the operating characteristics of these pumps, which were originally built by Cameron in 1928. Because these pumps were installed so long ago, there was no NPSH data available and the pumps’ best efficiency point was not known.

BP’s rotating equipment engineers contacted Hydro, a reliable pump service provider with whom they had a long and positive relationship. Their initial inquiry for a pump performance test led to a review of the pumps’ operating environment. Hydro’s engineers learned that one pump was a designated spare and three of the four pumps were being run at a much lower capacity. Block valves had been used to limit the discharge pressure for the three operating pumps in an effort to prevent leaks in the cooling water piping inside the refinery.

Hydro’s engineers agreed with the refinery’s rotating equipment engineers that it would be beneficial to obtain the pumps’ best efficiency point. Running the pumps too far back on their operating curves could create internal forces that would be harmful to the pumps and decrease their operating life. For this reason, the refinery decided to pull one of the bottom-suction pumps from service to be tested. However, before sending this pump to Hydro’s independent test lab in Chicago, they seized the opportunity to make modifications that would enable the vintage pump to meet current standards.

The pump was promptly sent to Hydro and a comprehensive engineering analysis was performed. Hydro’s engineers communicated with the refinery’s rotating equipment engineers to determine the modifications and upgrades that could be made.

Continue reading →