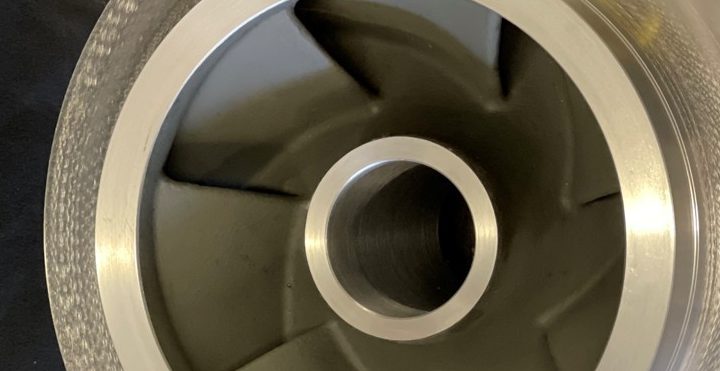

Hydro Parts Solutions recently provided a cast nozzle head to a Canadian oil and gas end-user. As is standard with Hydro’s cast parts, this complex component was:

- Scanned

- Reverse engineered

- Reviewed by Hydro’s engineering team

- Cast

- Final machined

- Compared to original model

Hydro’s Condition Monitoring system, Centaur, has aided many end-users in catching real-time faults in rotating machinery. In many instances, end users see the value of the system through a no-cost, on-site trial. This includes the hardware, installation support, commissioning, and monitoring starting from the date that the sensors are commissioned on-site. The purpose of the free trial is to allow a “proof-of-concept” evaluation period before a further commitment is made.

Hydro’s Condition Monitoring system, Centaur, has aided many end-users in catching real-time faults in rotating machinery. In many instances, end users see the value of the system through a no-cost, on-site trial. This includes the hardware, installation support, commissioning, and monitoring starting from the date that the sensors are commissioned on-site. The purpose of the free trial is to allow a “proof-of-concept” evaluation period before a further commitment is made.