Creative approaches that extend beyond original designs, standard tools, and traditional engineering practices can provide significant savings and higher reliability of pumping equipment. For example, in one such situation, the casing of a charging pump at a European nuclear plant had been over-pressurized and needed to be refurbished. Not only was the pump service radioactive, but the casing was also found twisted with its internal components unable to properly fit into the casing, and the machined surfaces out of alignment.

The original equipment manufacturer (OEM) of the pump stated that they could not repair the casing and that the only option was to purchase a new one. The nuclear plant’s engineers approached Hydro, Inc., a global aftermarket pump service provider, for assistance in finding a spare casing. When no spare was found, Hydro initiated a more detailed discussion with the plant about refurbishing the casing.

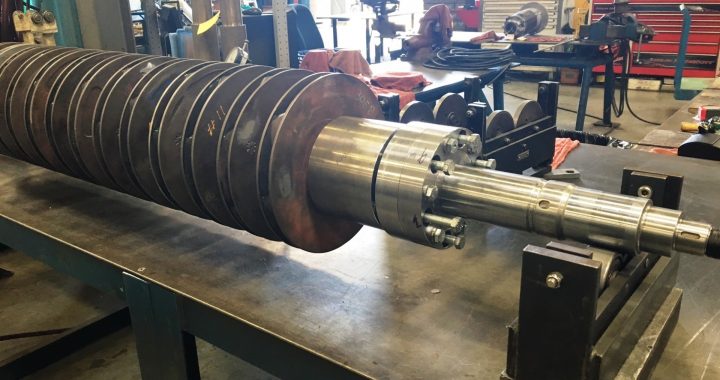

Hydro’s team inspected the pump, the casing, and the internal element and explored all possible options (Figure 1). Hydro was able to find an inventive solution by machining the casing in the contaminated state and developing creative methods to guarantee a proper fit-up when the casing repair was completed. Despite the OEM suggesting a new pump be purchased, the service provider was able to find an innovative and cost-saving way for the plant to repair the casing and reduce downtime. Continue reading