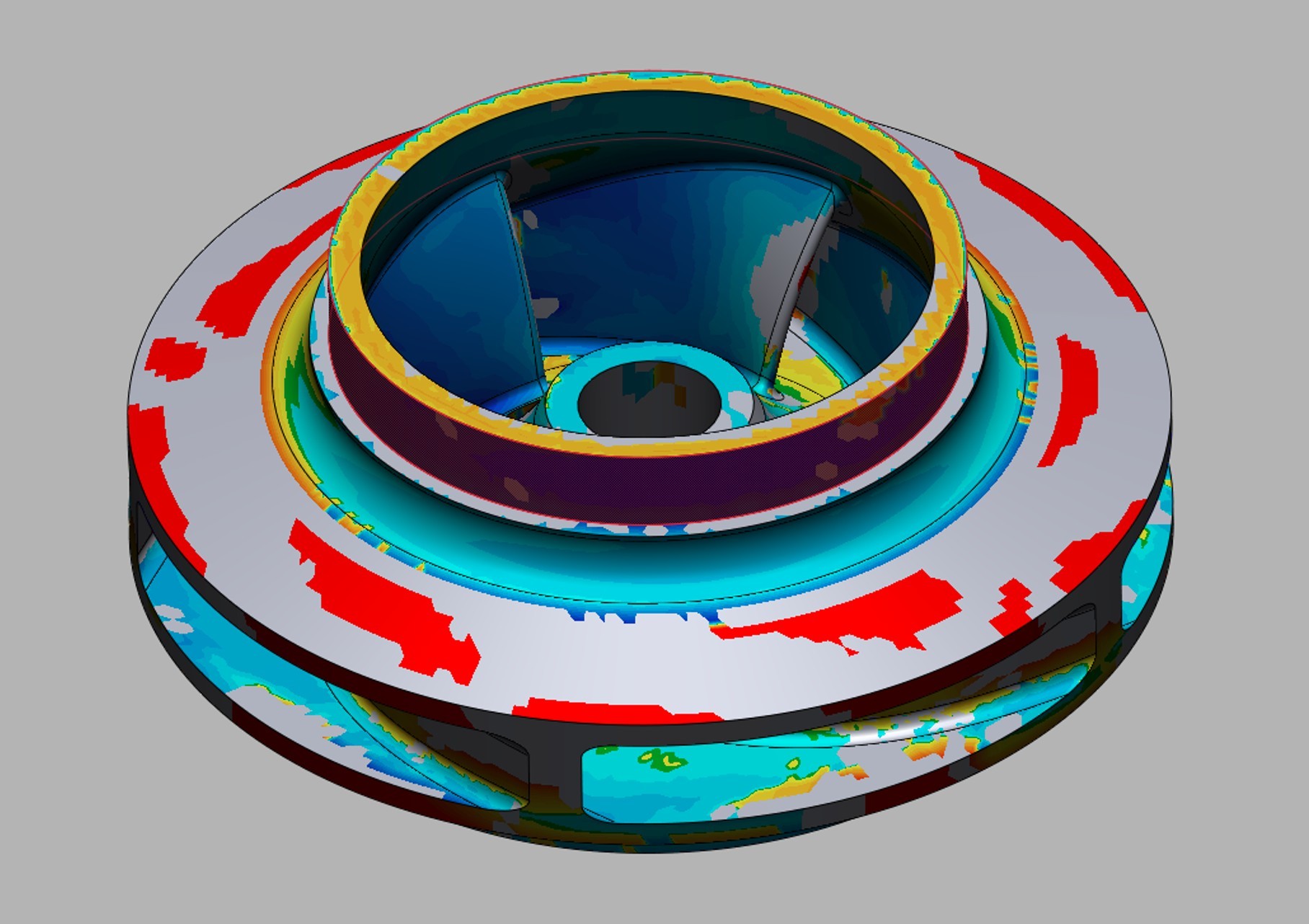

The destroyed sample used for reverse engineering

State of the Art Parts: A Gulf Coast refinery had the primary pump for a critical system at the HydroTex Golden Triangle facility for refurbishment. While the primary pump was in the shop, the backup pump operating on-site began to show signs of failure. The impeller of the pump being repaired had extreme wear and was unable to be reused. The shop needed to source an impeller in an expedited timeframe to complete the repair ahead of schedule and get the primary pump back in service before the backup pump failed.

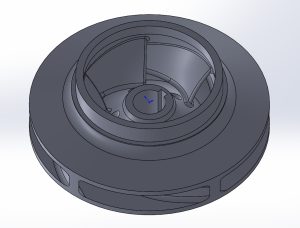

Completed 3D model

Hydro Parts Solutions was called in to provide a replacement impeller on an emergency delivery schedule. The sample that was available for reverse engineering had been destroyed during the operation, requiring the Parts Solutions team to use their pump experience and engineering background to recreate the component and ensure that it would meet the required performance.

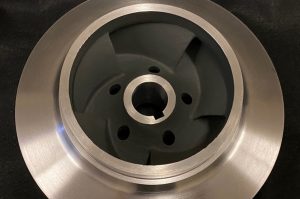

Final machined casting

With the critical timeframe in mind, the Hydro Parts Solutions team dedicated its resources to this project. They were able to reverse engineer the part, verify the model, design the mold, cast the component, and provide final machining within a 3-week time frame. The refurbished pump was delivered to the plant before the backup unit degraded further, avoiding costly downtime.

Comparison of scanned data to completed Model