With the advent of machine learning, great strides have been made in using Industrial Internet of Things (IIoT) technology to drive smarter and more efficient plant operation and maintenance. But how do you start on this connected plant journey and what is the ultimate destination?

Starting the process of implementing new technologies can be intimidating, but you don’t have to venture out into the digital frontier alone. This article maps out the journey from initial data collection to system optimization and points out some important guideposts along the way.

- Collect More Data, More EfficientlyThe first step for developing a connected plant may sound basic, but it is essential for everything that follows. Collecting the right data at high frequency intervals is the cornerstone of moving your plant into the digital world. Minimizing the time between collected data points and ensuring that your hardware has a range capable of detecting all failure modes will provide greatly improved line of sight to transient events and incipient problems.Collected data connects both artificial intelligence and human intelligence with monitored equipment. Data needs to be stored and analyzed in an environment where it is accessible by internal and external subject matter experts. With cloud-based access to information and automated alerts sent through email or SMS, equipment owners no longer need to jump through hoops to get information on current equipment health.Route-based maintenance or “islands” of information are roadblocks on the connected plant journey.

- Integrate Information on Plant Operation

Getting information on equipment condition is an important step forward, but to give this information perspective it is important to integrate it with data related to equipment design and operation. Collecting inputs such as vibration and temperature can help provide a clear picture of how the equipment is operating, but system data will help refine why it is operating this way.For example, inputting the original tested pump performance data can provide perspective on how much performance is degraded or how the operating point relates to the best efficiency point. Another example would be integrating information on plant load or flow control valve position; correlating system load with equipment behavior provides perspective on how operation is directly affecting monitored inputs.

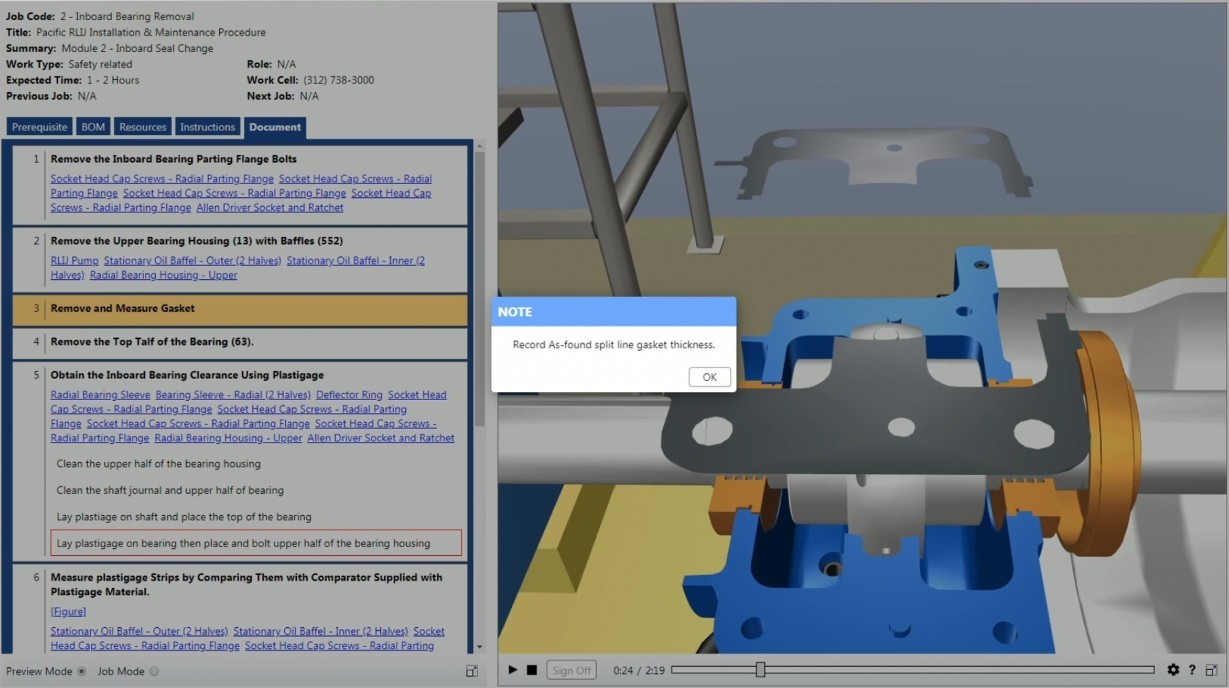

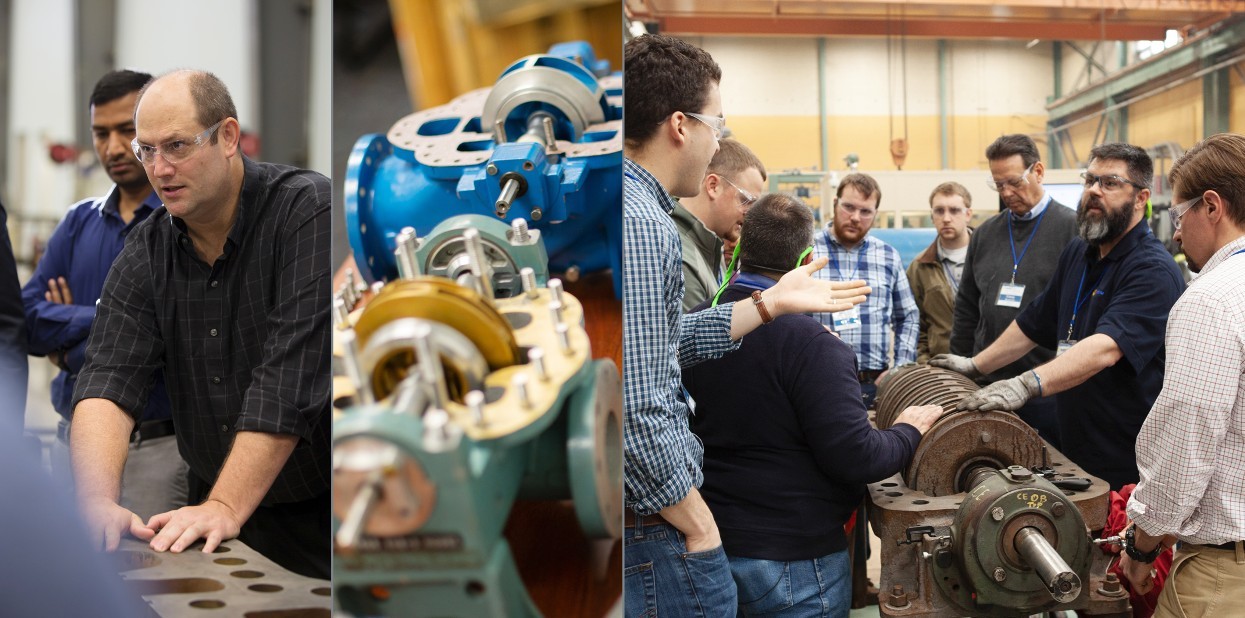

- Predict Future Performance and ProblemsOnce data points are being collected at high frequency intervals and operating data is available, the groundwork is established to start becoming more predictive. Monitored inputs can produce a detailed picture of current condition. Correlating different operating modes with changes in observed data provides a basis for anticipating future behavior under varying conditions.In this phase, the analytical software used becomes an important factor as algorithms are finetuned to provide more accurate predictions. Actual outcomes are fed back into the software to provide validation of these predictions and train it to better interpret monitored information. On the human side, experience with equipment design, maintenance, and behavior are crucial for supporting the machine learning process. This human element is also critical in assessing risk based on predictions supplied by the software.

- Detect Anomalies Instead of Blind AlertsWhile automated alerts are a good first step in making your digital resources work for your maintenance strategy, considerable value is realized when your system can differentiate anomalies from expected behavior. This requires training AI-driven software to recognize “normal” equipment behavior.A pump may exhibit high vibration from its commissioning and frequently exceed recommended alarm values- but this behavior does not necessarily represent a maintenance concern. Conversely, equipment with a smooth operating history that suddenly exhibits a vibration spike indicates a problem even if that vibration does not reach the set alert boundary.Separating anomalies from steady trends will greatly improve identification of incipient problems so that actions can be taken before substantial damage occurs.

- Diagnose Root Causes with ConfidenceOnce the software can classify different types of behavior, it can be taught what failure modes are associated with that specific set of observed conditions. This is another area where having a subject matter expert support software development is very important. With expert input, the software can learn to recognize patterns in the monitored data and suggest possible failure modes as they develop in real-time.When monitoring software reaches the point where it can intelligently diagnose events, it provides the plant with actionable information. Instead of starting a root cause investigation with a blank sheet of paper, you can quickly perform validation steps for suspected failure modes. This can significantly shorten downtime caused by equipment unavailability.

- Get Proactive and Eliminate Potential Problems

With the software’s advanced diagnostic capabilities trained, the output can be used to develop a proactive approach to maintenance. When failure modes are recognized, engineered solutions can be developed to extend equipment life. After solution implementation, the software can analyze the efficacy of the fix and continue to monitor equipment condition to make sure that new failure modes were not introduced.Innovative methods of monitoring or analyzing the data can be used to further understand and trend the health of the system. For example, instead of just monitoring vibration, parameters can be measured that allow the software to calculate efficiency and correlate this to changes pump wear ring clearance. By trending more sophisticated values, your plant can get closer to the monitoring the causal factors of degradation rather than just measuring their effect.

- Optimize Design and OperationThe end of the connected plant journey is an optimized approach to maintenance, operations, and engineering. Developing technology that does the bulk of the processing and analytics frees up our human resources to focus on what they do best- using their experience and insight to interpret grey areas, assess risk, and plan ahead.With a proactive maintenance plan, equipment condition can be trended and maintenance intervals extended by making changes that positively affect equipment health.On the operations side, understanding efficiency can inform decisions of what machines to run in parallel. Being able to operate the most efficient piece of equipment will result in energy savings, directly reducing the cost of operation. Historical data can also be used to optimize the combination of equipment being run at different plant loads.Plant engineers can use the connected plant output to take a deeper look at their systems and determine if the original design still suits current operation. Equipment design can then be optimized to provide operation that is safer, more efficient, and more reliable.Lastly, a well-developed IIoT strategy will help equipment, equipment owners, and subject matter experts stay connected to the data and to each other, optimizing communication and flow of information.

Wireless Condition monitoring, the perfect combination of man and machine. Where human experience and secure machine data collection create a long-term strategy for your operation. Beyond basic data trends machine health, take a chance at Centaur for your rotating equipment. Apply for a free trial today.

Note: This article was originally published on bicmagazine.com.