A hot potassium carbonate pump at a nitrogen fertilizer plant had been experiencing elevated vibration at vane pass frequency. Recognizing that this vibration likely contributed to shortened equipment life, the end user partnered with Hydro to investigate the root cause of the vibration and modify the pump as necessary to remove it.

When the vibration and performance indicated that it was time to take the pump out of service for refurbishment, it was sent to Hydro’s Chicago service center for inspection and analysis. The inspection showed significant damage caused by component contact and erosion.

After reviewing the inspection data, an engineering analysis was completed on the design to determine what could be done to eliminate the vibration. The engineering team determined that the vane pass vibration was related to shock waves caused by the high energy fluid impacting the volute lip. This was intensified in the first stage, where the 4-vane impeller was discharging into a dual volute. The volute lip was reprofiled to reduce this impact and provide a smoother transition from the impeller exit into the volute passage.

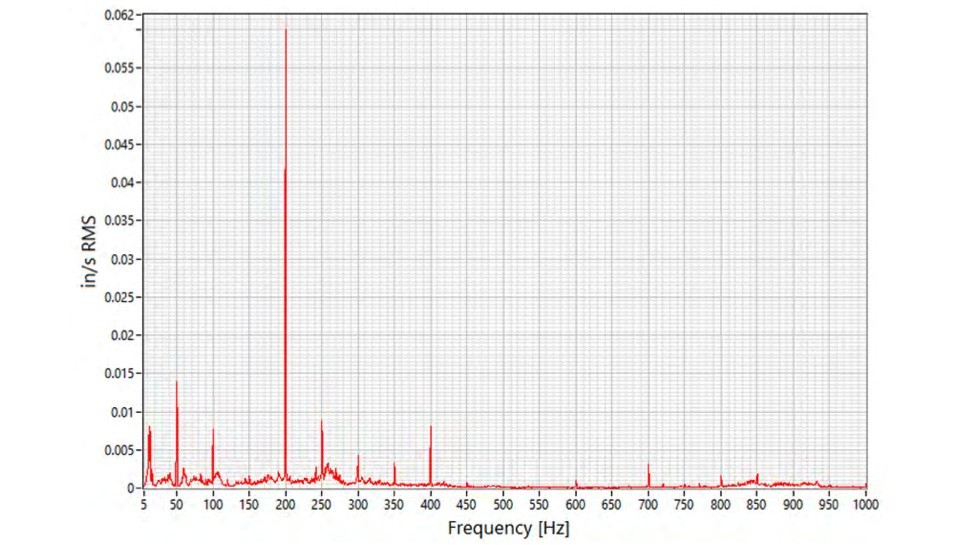

The upgraded design was tested in Hydro’s performance test lab. This gave the end user confidence that the hydraulic performance of the pump had not been negatively affected by the volute lip geometry modification. It also verified that the vibration amplitudes had been reduced. After successful testing, the modified pump was returned to the field, where it continues to run smoothly.

1. Reduced Vane Pass Vibration Observed During Testing