Join Hydro South at Booth #62 (next to the Knowledge Center Hub)

Join Hydro South for a one-day Basic Hydraulics training seminar. Presented by Hydro’s Bob Jennings, this course will cover basic pump design, pump and system curves, NPSH, and other fundamentals that pump owners need to know for reliable operation.

Hydro South recently completed the overhaul of a Condensate pump at its facility outside of Atlanta, GA. This pump is a vertical can-type, motor-driven centrifugal condensate pump installed at a nuclear power facility in the Southeastern US. The condensate system has three identical pumps that operate in parallel (with a maximum of two pumps normally in service and an installed spare).

The pumps are designed to operate continuously for the normal 18-month fuel cycle with no maintenance attention. Because the condensate system is critical to plant operation, it is imperative to verify the performance of the pump before getting it back in service. Continue reading

The pump industry faces a challenge in keeping up with changing efficiency regulations. Programs such as the Hydraulic Institute (HI) Pump Test Lab Approval (PTLA) are helping companies adhere to these standards. Here, we see how Hydro, Inc. made history with the first HI PTLA certification.

Written by: Michelle Segrest

Publisher: World Pumps / June 2016

With an engineering first approach, Chicago’s Hydro, Inc., proves the impact of redesigned and engineered pumps by testing their real-time hydraulic and mechanical performance at its state-of-the-art Test Lab. It is in the 46,000-square-foot- facility that Hydro develops and implements engineering modifications for improving the performance of critical pumps and then verifies that performance in the lab.

Thanks to high-quality capabilities in testing vertical, horizontal, and submersible pumps, Hydro made history in September 2015 by becoming the first recipient of full certification of the new Hydraulic Institute Pump Test Lab Approval program.

This new industry standard is designed to assist pump OEMs and other pump test laboratories to improve their current laboratory procedures and policies by working with a third-party auditor to develop and maintain accurate, uniform and repeatable pump testing protocols. The program also helps participating organizations adhere to the requirements of the international test laboratory accreditation standard (ISO 17025) concerning test measurement equipment.

“Hydro’s test lab is unique because it was designed to support the aftermarket by having the flexibility to test a wide range and variety of custom engineered pumps,” said George Harris, Hydro CEO and Founder. “Since it is not incorporated in a plant which manufactures new pump production, as is the case with many large OEMs, it is possible to test a customer’s pump in 1-to-3 weeks lead time. This is very important because customers who need a certified test, need the pump tested quickly.”

Since it opened in 2010, Hydro’s 5,000-Horsepower Test Lab has helped to troubleshoot problems with pumps in the field by isolating the pump from its system in a controlled environment to simulate field conditions in a safe manner.

“Hydro remains independent of the constraints that can be imposed by relying on existing hydraulic designs and manufacturers’ predicted performance curves,” said Jeff Johnson, Vice President, Hydro, Inc., a 41-year industry veteran who was instrumental in the design and construction of Hydro’s Test Lab. “All of these efforts ultimately lead to a more reliable and well understood pump performance.”

Single-stage horizontal split case (BB1) pump test with customer motor – test loop.

Hydro is a global leader in the pump aftermarket repairs, upgrades and engineering solutions.

Pump companies typically fall into one of two categories: the original equipment manufacturer (OEM) that design, build, and sell pumps; and smaller, local machine repair shops. But Hydro offers the pump industry the best of both worlds. George Harris, one of the original founding engineers and current CEO, explains Hydro’s unique worldwide market position: “We have developed a unique niche where we have the engineering services, the testing capabilities, and the worldwide footprint that the large OEMs have, but we still maintain the exibility and the cost-effectiveness of the smaller companies.”

Harris also emphasizes that engineers are the heart of the company. Nick Dagres, the Vice President of Nuclear Operations in Chicago, notes that “We focus on aftermarket services and support. We implement engineering modifications to improve the performance of pumps that are out in the field.” By offering pump rebuilding, engineering, and upgrading at each service centre, Hydro can more effectively service the special needs and requirements of customers in each region. Staying close to the customer is one of the fundamental tenets of Hydro’s strategy and culture.

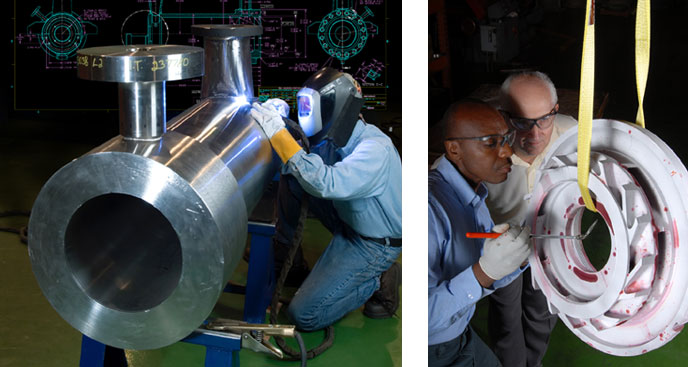

(Left) Hydro’s long list of services include welding-related repairs, such as performed on this 2 ½” Pacific RL IJ charging pump. (Right) A thorough quality inspection is carried out by Hydro’s detail oriented engineers.