Upgrade in Action: HydroSeal

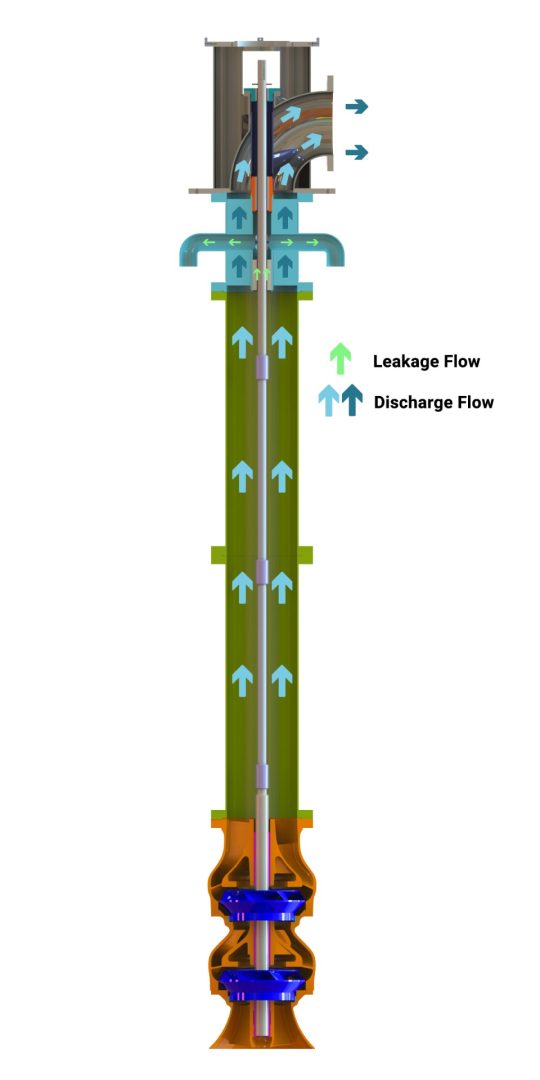

Vertical pumps have reliability and maintenance considerations unique to their design and application. One of these considerations is the pump seal design. Many vertical pumps rely on packing in lieu of mechanical seals. While it is a less sophisticated design, packing has benefits for vertical pumps, including greater ability to handle fluid with particulates, less sensitivity to misalignment, and greater stiffness and damping provided at the seal location. However, packing also has multiple disadvantages, foremost of which is the need to continuously adjust the packing gland to maintain the desired leakage rate and the requirement that some fluid must leak to the atmosphere. The cost associated with replacing worn components in the packing area is another notable drawback.

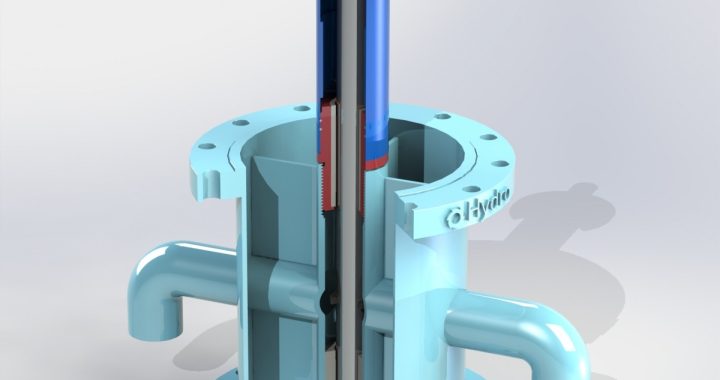

In cases where any of the disadvantages associated with packing or a mechanical seal noticeably impact reliability or the cost of operation, upgrading to a seal casing design is an attractive alternative. This is the decision that a pulp and paper mill in the Southeastern US made when experiencing reliability and environmental concerns in their River Water pump system. Faced with the need to install a new sealing device, they decided that the ability to avoid aboveground leakage and eliminate time-consuming periodic maintenance justified the investment in a vertical pump seal casing.

Read the full case study in World Pumps March/April 2024 edition.

Learn more about Hydro’s Hydro South service center and Hydro’s Engineering Services.

A major utility company had a Foster Wheeler 60 DF horizontal split case circulating water pump that required repair. They decided to complete the refurbishment during a 14-day unit outage by using the

A major utility company had a Foster Wheeler 60 DF horizontal split case circulating water pump that required repair. They decided to complete the refurbishment during a 14-day unit outage by using the

A critical vertical pump for a 750 MW unit was sent to

A critical vertical pump for a 750 MW unit was sent to