Innovations in Thrust Measurement

Thrust is an important factor in vertical turbine pumps because it directly affects the performance and reliability of the pump. Excessive axial thrust can cause the motor thrust bearing to wear faster, run at a higher temperature, and/or fail if overloaded. This results in a higher total cost of ownership by reducing equipment operating life, forcing unexpected downtime, and requiring costly emergency work.

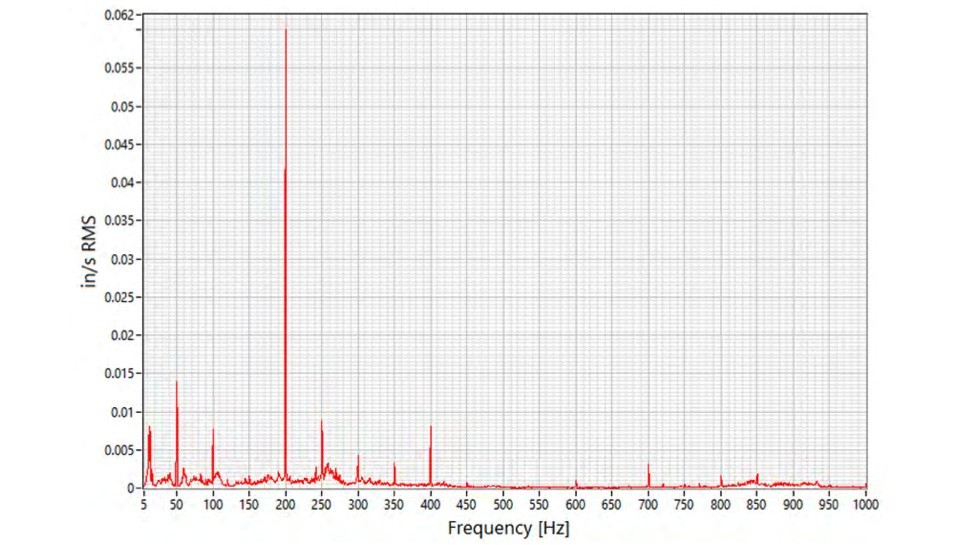

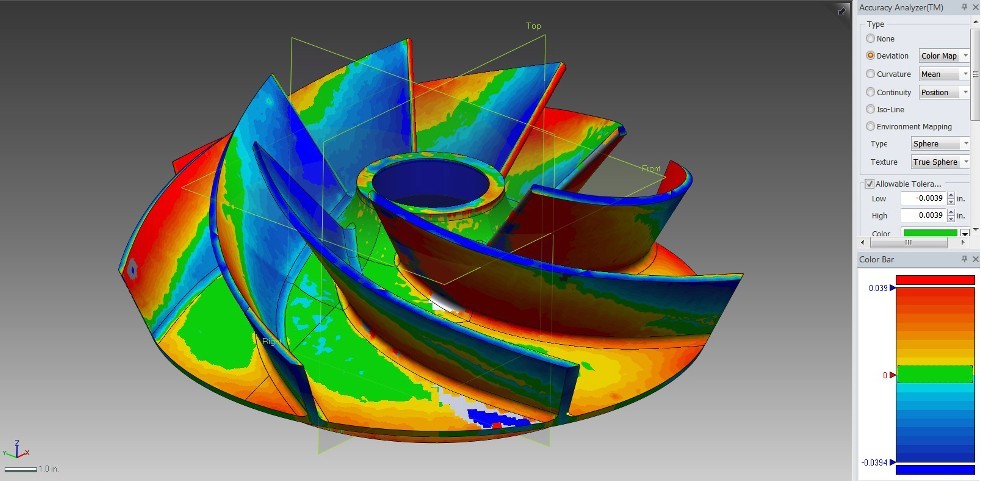

Historically, thrust has been a calculated value based on the impeller design and other pump parameters; this calculation is an approximation and has a margin of error. Axial thrust can be more accurately assessed through testing, but direct measurement of the thrust across the profile of a pump performance curve is not typically performed by OEMs.

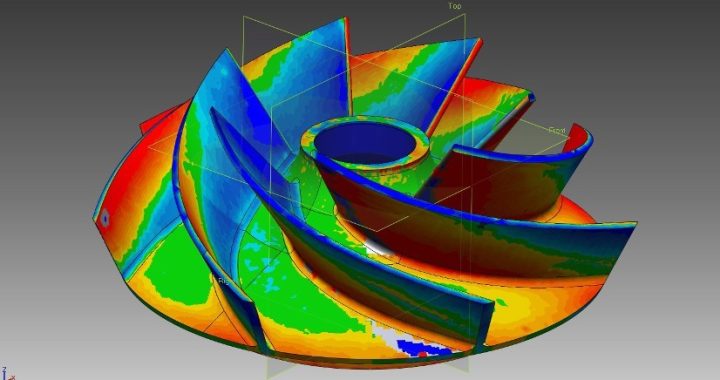

In support of a customers’ request to better understand the repeated failure of a vertical turbine pump, Hydro’s Test Lab and S. Himmelstein and company developed a thrustmeter that provides users with an accurate and reliable measurement of thrust across the tested performance curve. This measurement was not only more accurate than the calculated thrust values, it provided insight beyond a single operating point.

By monitoring critical pump and motor data, the end user was empowered to make the best possible decision for their equipment and plant.

Read more about this innovation in our joint white paper, published with Pumps & Systems magazine.

Learn more about how Hydro’s Certified Performance Test Lab and how Hydro can support you in better understanding and optimizing the performance of your equipment.