What applications should be considered for condition monitoring?

Systems that would benefit from real-time measurement and assessment such as machines that are critical to plant operation or a specific production process. In addition, “problem” machines that would benefit from 24/7 monitoring and analysis to better understand the root causes of failure.

What types of equipment are supported through this approach to condition monitoring?

The system can be utilized on pumps, gearboxes, motors, compressors, fans, blowers, mixers, etc.

How does the system help me operate my facility more efficiently and safely?

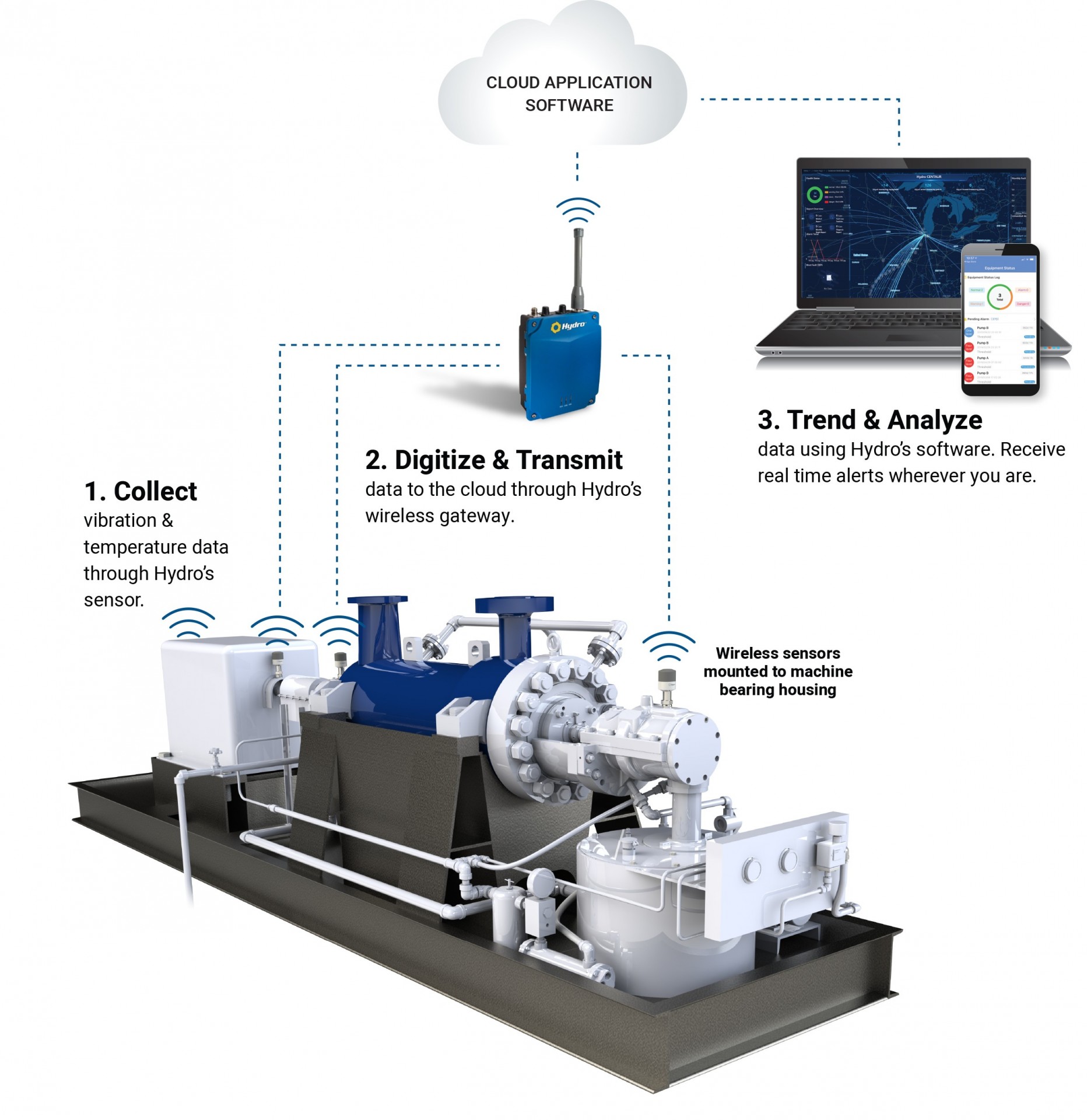

The system monitors the health of industrial equipment, helping to optimize operations and identify problems before equipment failure. The network of sensors provides useful machine condition data and timely alerts if alarm thresholds are exceeded. By collecting data remotely and continuously, equipment health is better understood, failure modes can be identified and classified in real-time, and improve can be made to preventative maintenance strategies.

What types sensors are available?

Several sensors are available to measure different key variables to determine machine health. Hydro offers the following instruments with other sensors available upon request:

- Wireless Single Axis Vibration and Temperature Sensor

- Wireless Single Axis Vibration and Temperature Sensor

- Submersible Single Axis Vibration Sensor

- Pressure Sensor

What is a gateway?

A gateway is an IIOT device enabling the secure collection of wirelessly transmitted data from machines and subsequent transmission of data to a specific server for further analysis. The gateway is powered by 110/220VAC or an internal battery for wireless operation. Each gateway can host up to 45 total sensors and can use up to three methods to data transmission to a specified server.

What is a transmitter?

A transmitter is an IIOT device enabling the secure collection of data from two wired sensors – either the submersible single axis vibration sensors or pressure sensors. The transmitter is powered by an internal battery, which also provides power to the connected sensors. Transmitters send collected data to a gateway for further transmission to a specified server.

Are cables required to support the hardware?

Cables are not required to support the wireless sensors available. Cables are required to connect submersible single axis accelerometers and pressure sensors to a transmitter. There is a power cabled required for a 120/220VAC powered gateway.

What is the range of the wireless sensors?

The wireless sensors have a signal range to their assigned gateway of approximately 1,000 feet (~300 meters), clear line-of-sight.

Is the hardware rated for hazardous locations?

Yes, all hardware available has an ATEX/IECEx marking of “Ex ia IIC T4Ga”. This certification level is part the “Intrinsically Safe” category, applicable to divisions 1 and 2, equivalent to US standard “UL913/FM610”, and equivalent to Canadian standard “CSA C22.2 No. 157”.

What environment is the hardware suited for?

The hardware is rated for operation in industrial environments. More specifically, all hardware is rated for working ambient temperatures from -40 to 158 ̊F / -40 to 70 ̊C, however, the sensors have been installed and used in temperatures that exceed this limit.

How often does the system collect data? Is this interval dynamic?

Sensors can collect and transmit data samples at programmable intervals. The most typical collection interval is a time waveform once per hour and an overall value every 5 minutes—this practical strategy helps to maximize battery life while providing insightful data that is sensitive to process condition changes. However, if an equipment event occurs and preset warning or alarm thresholds crossed, the sensor will transmit the data and a warning when the event occurs.

What is the maximum number of sensors that a single gateway can support?

Each gateway can host up to 45 total sensors. If additional sensors are required, additional gateways would need to be provided in the deployment.

How is data transmitted to a gateway?

Data is transmitted to the gateways via 2.4 GHz radio frequency. Transmission uses ZigBee protocol, based in the IEEE 802.15.4 specification, to deliver a low-power transmission to facilitate a longer device battery life.

How is data transmitted to a server?

Data is transmitted to a server from a gateway using a cellular connection, Wi-Fi, or a Local Area Network (LAN). By having three options available, the optical communication method can be chosen based on the needs of the application or location.

Is a customer IT department required to support data transmission?

When utilizing a cellular network, limited or no support from customer IT is expected. However, if Wi-Fi or LAN are to be used customer IT will need to support data transmission during installation/commissioning.

What server is used to store data?

Hydro offers a cloud-based server supported through Amazon Web Service (AWS). In specific applications, a dedicated local server may be used.

Does the software allow users to view historical trends?

Yes, the software trends data such as acceleration, velocity, displacement, temperature, pressure, etc. over time looking for specific events as result of operational changes and longitudinal machinery degradation.

Does the software have diagnostic tools available to diagnose machine conditions

Yes, the software has a full suite of analytical tools including trends, time waveform, frequency spectrum, ‘multiple waveform’, ‘multiple spectrum’, trend-waveform-spectrum, temperature trends, cross-phase, waterfall, and many more.

Does the software have alarm levels and the ability to send automated alerts?

Yes, automated or manual alarm levels can be programmed for each unique data acquisition measurement available, in addition, if those thresholds are crossed an automated e-mail, SMS message, or software alarm can be directed to a customized list of Hydro, customer, and/or third-party personnel.

Does the software have Artificial Intelligence (AI), and can the AI detect failure modes?

Yes, the software has AI algorithms built in to detect failure modes common among rotating equipment. In addition, as failure modes are experienced machine learning algorithms continue to develop machine specific failure modes for a given machine.

Does the software have a method to check device battery level?

Yes, the software has the capability to alert you if the battery is low and the expected days remaining based on the measured voltage and data acquisition strategy.

Does Hydro offer software training?

Yes, Hydro offers software training as needed. The basics are typically covered in one session with additional sessions scheduled as personnel change or customers require more in-depth specific training.

Does Hydro offer integration with existing site historian systems such as PI, System 1, and SCADA?

Yes, Hydro offers integration with customer historians to synergize disparate systems. Hydro can integrate with systems such as PI, System 1, SCADA, and any EAMs.

How are the sensors and hardware activated?

Wireless sensors are activated with an internal physical switch accessed by unscrewing and removing the sensor cap. Gateways and transmitters have a similar physical switch accessed by opening the respective access covers. Submersible single axis vibration sensors and pressure sensors are activated when they are physically connected to an active transmitter.

How are sensors mounted to machines?

Wireless sensors are mounted to equipment via a M6 stud, epoxy, or a magnet (provided by Hydro as needed). Submersible signal axis sensors are mounted via a M6 stud at the specified desired submerged location. Pressure sensors are connected to a pressure tap in the specified pipe and able to be isolated by an appropriately designed valve.

What is required to install a gateway?

A gateway typically required 120/220VAC power supply. If a cellular signal is used, the gateway must be placed in a position to receive reception from the cell tower and also be able to communicate with connected sensors. Additional equipment may be required for remote or complex installations that prohibit the more typically available cellular reception.

How long does it take to install sensors and associated hardware?

Wireless sensors can be mounted to machines and activated in minutes. Gateway installation and activation can be completed in minutes as well, provided a power supply has been identified in the appropriate proximity to the monitored machines. Submersible single axis sensors and pressure sensors require more preparation work before installation. Once ready, the installation and activation are often completed within a few hours.

What type of maintenance is required to support the condition monitoring system?

All firmware and software updates are processed automatically. The only maintenance required is battery replacement of the wireless sensor(s) and transmitter(s) in each installation.

How secure is the system?

The system is a closed network and is secure from unauthorized usage. Stringent security standards are maintained. All data packets are authenticated at each layer, and encrypted end-to-end, to protect critical information from outside intrusion or hackers.

How secure is the software website and how is it accessed?

Software is accessed through a secure website and includes discrete usernames with user specific credentials.

Is there a warranty and what is covered under the warranty?

Hardware shall be warranted for a period of twelve (12) months from the initial operation or eighteen (18) months from the delivery date of the hardware. Software shall be warranted for a period of one hundred eighty (180) days from delivery date. See Terms and Conditions for more details.