-

Centaur Software

Centaur’s Enterprise Predictive Maintenance (EPM) software is a cloud-based solution that combines powerful AI-driven analytics with an intuitive, user-friendly interface, making advanced condition monitoring accessible to everyone with internet access.

With live monitoring and real-time alerts, Centaur empowers your team to make smarter, data-driven decisions that reduce downtime and improve operational efficiency. It's the perfect solution for staying ahead in today’s fast-paced industrial environments.

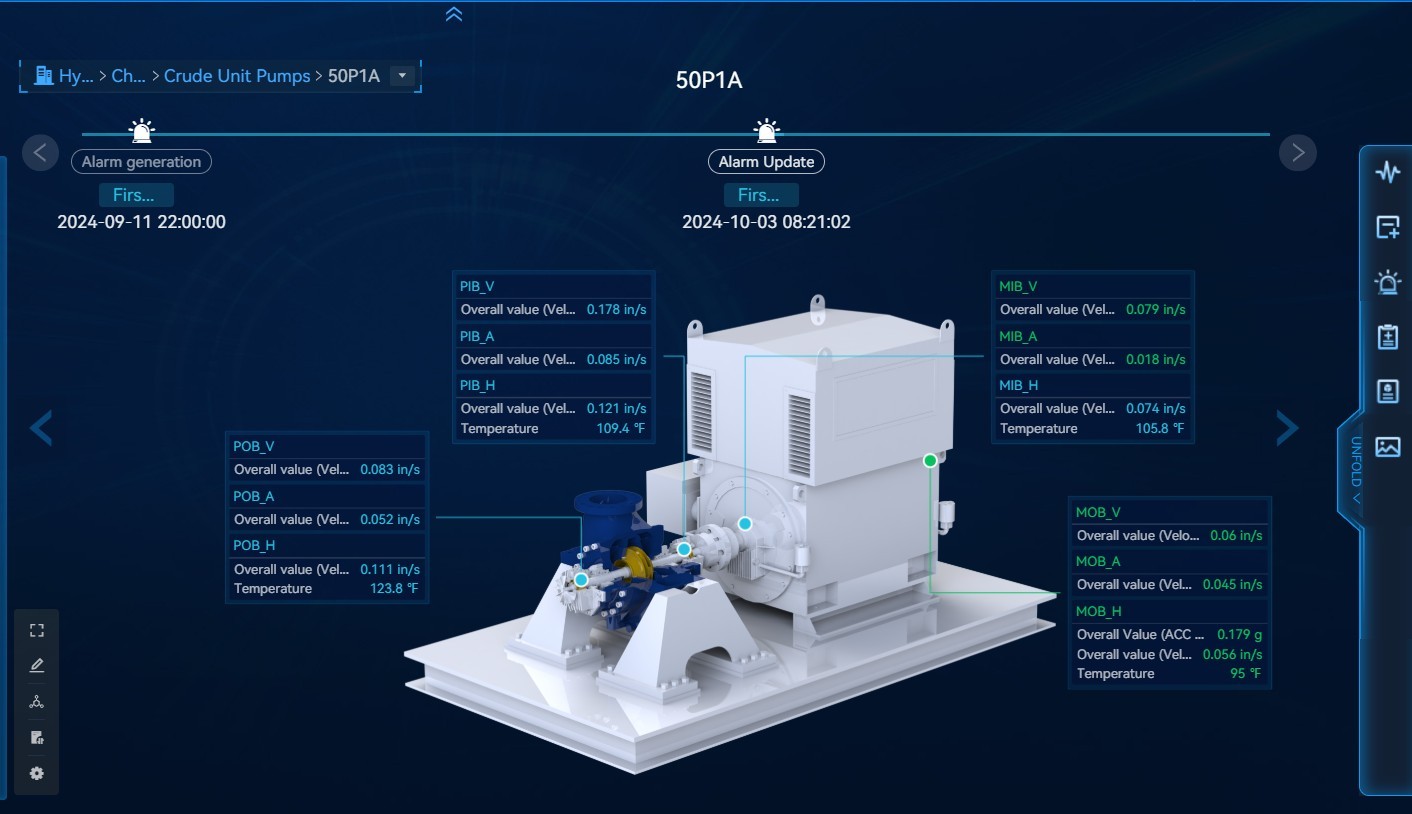

Digital Twin Asset View

The Digital Twin delivers a representative equipment model overlaid with real-time monitored data. This information is color-coded to highlight threshold levels, allowing an immediate assessment of equipment condition. Additionally, we can also import real photos and use those in the software in lieu of the digital image.

Beyond a simple depiction of monitored equipment, the Digital Twin integrates advanced analytical tools within the software to establish a powerful asset management platform.

Key Features

- Live Visual Insights: Advanced real-time representations of all pumps and systems under surveillance provide enhanced operational visibility.

- Sensor Location Indicators: Clear markers display the exact location of each installed sensor, ensuring precise tracking and management.

- Performance Monitoring: Live data streams illustrate equipment performance, with color-coded indicators highlighting threshold levels and warnings when sensors exceed alarm limits.

Email Alerts and Alarm

Access From Anywhere, Anytime

- Web-based software accessed anywhere, anytime, on any internet-connected device

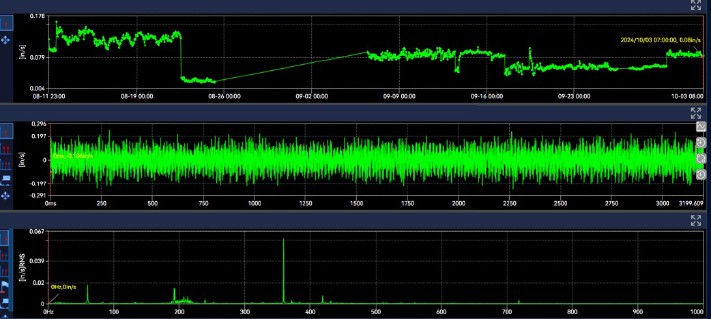

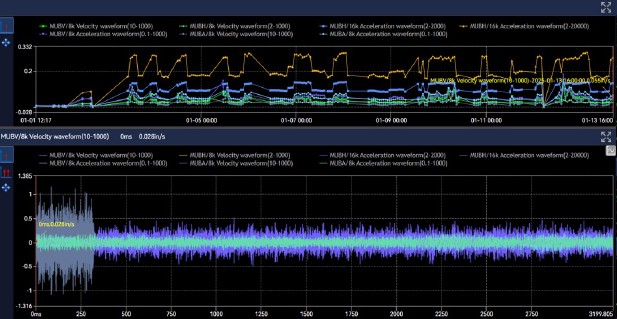

- Real-time and historical vibration and temperature trends

- Alarm level threshold notifications via email, text message, and desktop application

- Customizable notifications, user roles, and permissions

- Equipment History and Diagnostics Log: Centralized tracking of notes and diagnostics with date stamps for accurate record-keeping

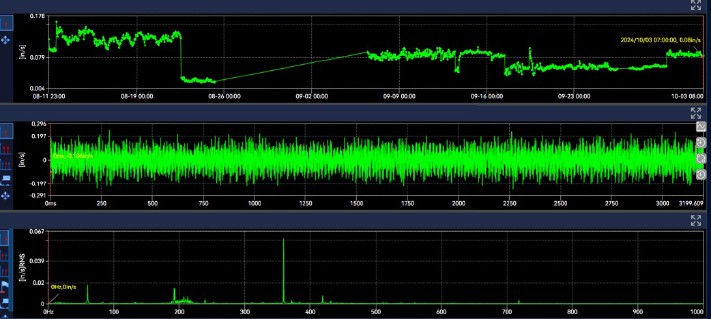

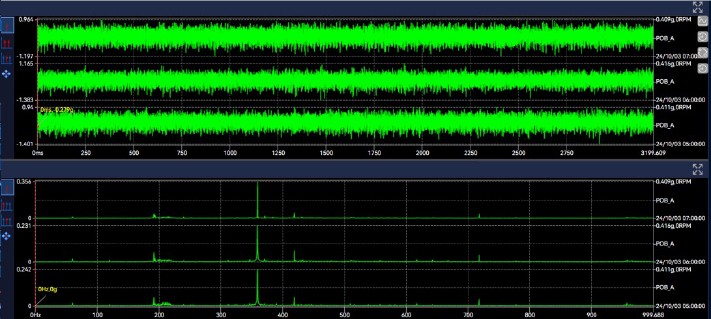

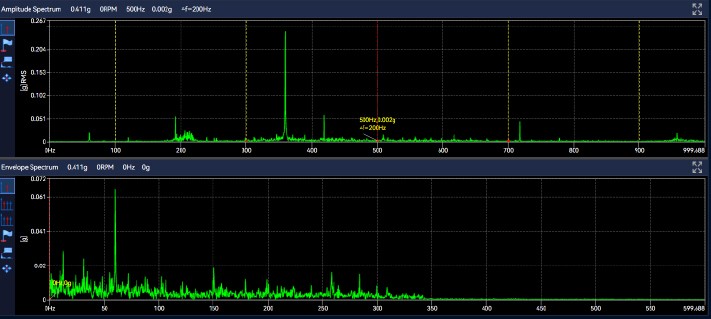

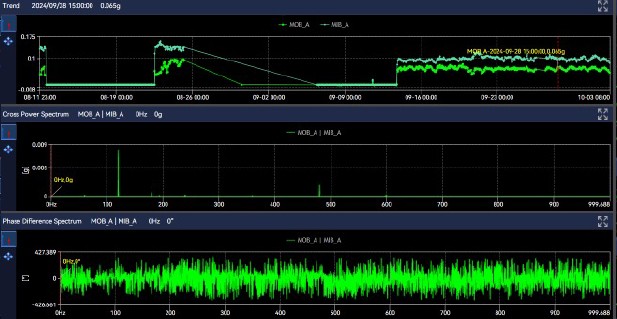

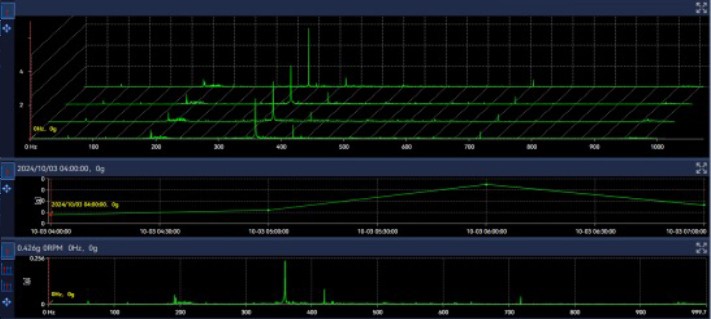

Powerful Analysis Tools

Our comprehensive suite includes analytical tools for trend analysis, frequency spectra, and fault monitoring. Enhanced by AI and System Generated Reports, our tools provide quick analysis and remediation recommendations with seamless integration to PI, System1, SCADA and other plant historians.

Don't be a stranger

We're here to answer any questions you may have and to talk about how to get started.

Get in touch and we will get right back to you. Let's do this.