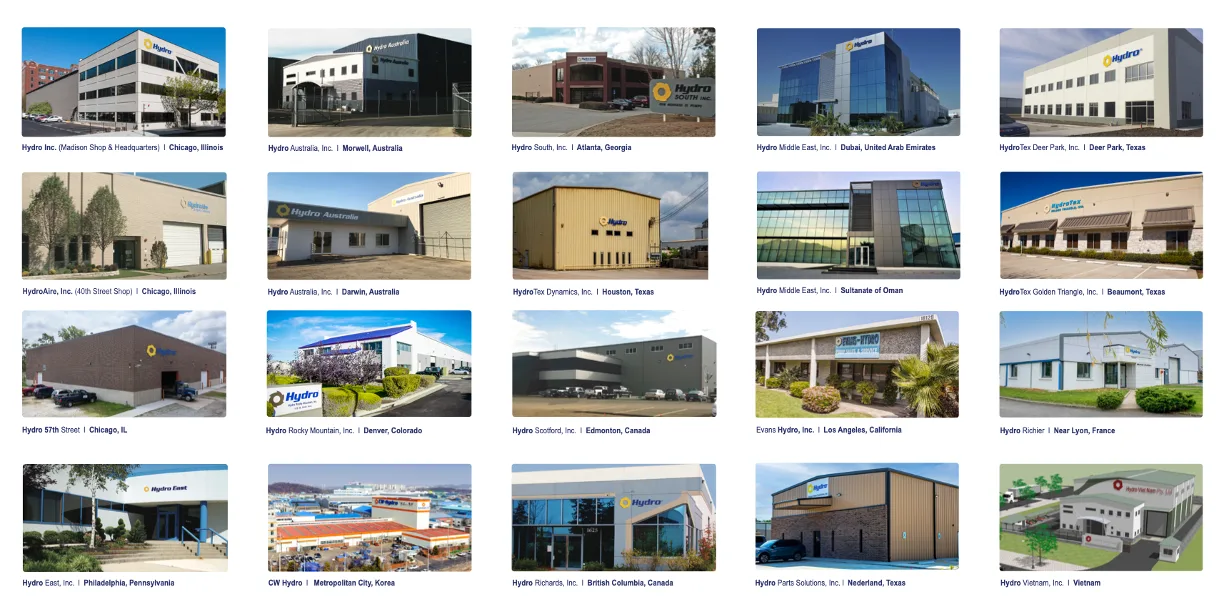

From its first storefront on Diversey Street in Chicago in 1969, Hydro has grown into an expansive service network that supports rotating equipment users worldwide. Our extensive footprint ensures that we can deliver our hallmark quality and exceptional customer service to clients across the globe.

From its first storefront on Diversey Street in Chicago in 1969, Hydro has grown into an expansive service network that supports rotating equipment users worldwide. Our extensive footprint ensures that we can deliver our hallmark quality and exceptional customer service to clients across the globe.

Our geographic expansion has been accompanied by the growth of our engineering capabilities and our application knowledge. While all Hydro facilities are guided by the same processes and standards, we have also developed targeted capabilities, tooling, and experience in our individual locations to serve their local markets. This service base is complemented by our centralized global engineering division, with experts in disciplines such as hydraulic design, metallurgy, and vibration analysis and troubleshooting.

By leveraging a diversity of expertise and resources, we can cater to the unique needs of each customer, ensuring timely and effective solutions that uphold our high standards of excellence. Some examples of niche capabilities within our network that can be leveraged by Hydro’s customers include:

By leveraging a diversity of expertise and resources, we can cater to the unique needs of each customer, ensuring timely and effective solutions that uphold our high standards of excellence. Some examples of niche capabilities within our network that can be leveraged by Hydro’s customers include:

- Our clean room at HydroTex Deer Park

- Reciprocating pump repair, troubleshooting, and engineered upgrades

- High-capacity vertical pump repair and re-engineering at Hydro East

- Nuclear safety-related and code repair, parts, and new units at the HydroAire Madison St facility

- Access to expedited cast parts through Hydro Parts Solutions

- 5-axis machining, including milled vane impellers, at HydroTex Dynamics

- Oil field services equipment through Hydro Middle East

Our growth has strengthened—not diminished—our commitment to local service excellence. Each service center combines on-site, dedicated engineering resources with established local supplier networks to deliver timely, effective support. We believe that communication is the cornerstone of successful collaboration, and we work hard to foster a culture of transparency and engagement.

Find your local Hydro service center here.

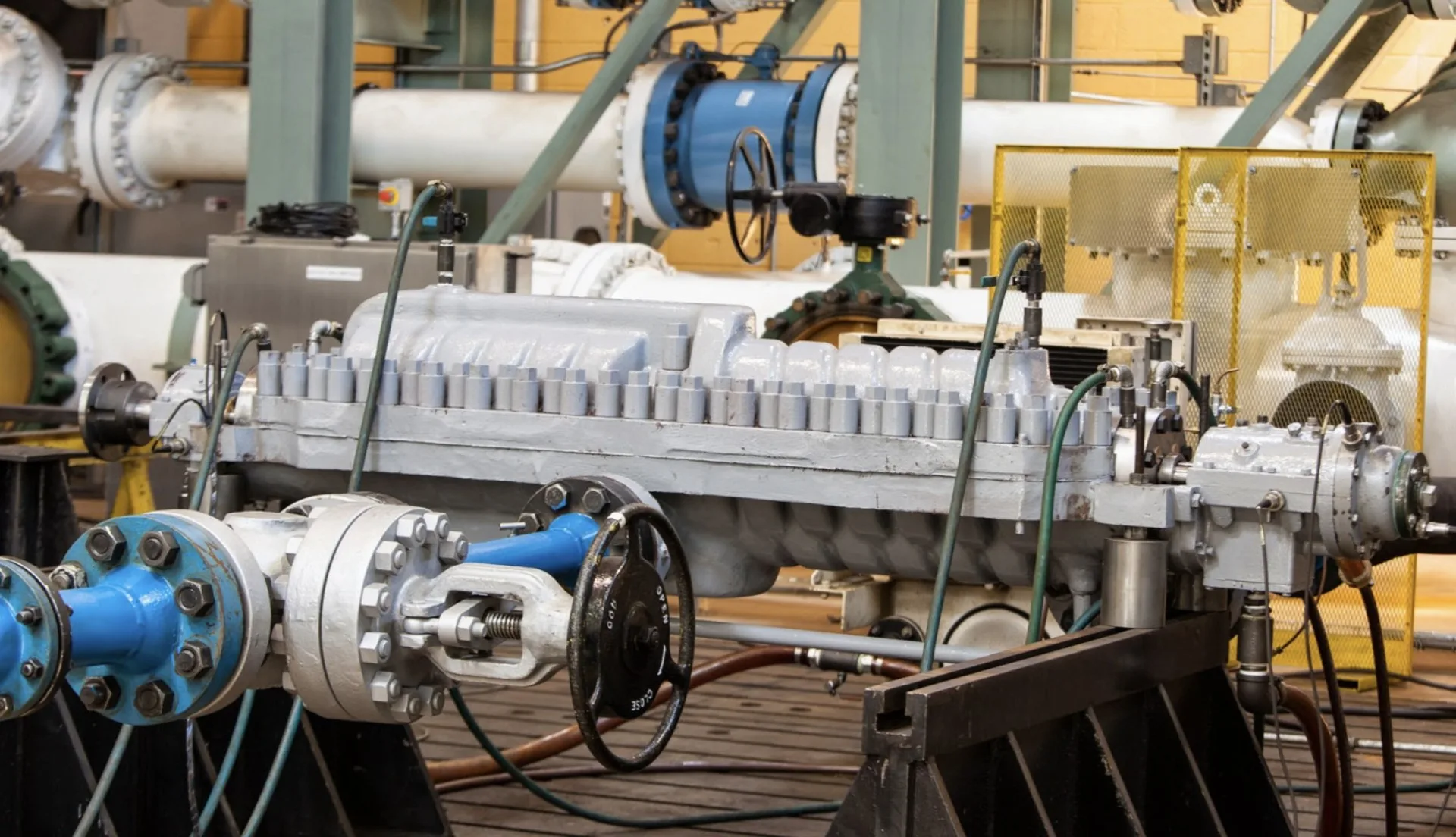

Performance testing in a controlled environment is an important tool for pump designers and users alike. Understanding how the pump will react hydraulically and mechanically throughout the full range of operation enables improved equipment reliability, optimized efficiency, and reduced operating and maintenance costs.

Performance testing in a controlled environment is an important tool for pump designers and users alike. Understanding how the pump will react hydraulically and mechanically throughout the full range of operation enables improved equipment reliability, optimized efficiency, and reduced operating and maintenance costs. To support end users in understanding equipment health and performance, Hydro built its Certified Performance Test Lab at the HydroAire 40th Street service center in Chicago. Our test lab was the first to be certified by the Hydraulic Institute’s

To support end users in understanding equipment health and performance, Hydro built its Certified Performance Test Lab at the HydroAire 40th Street service center in Chicago. Our test lab was the first to be certified by the Hydraulic Institute’s

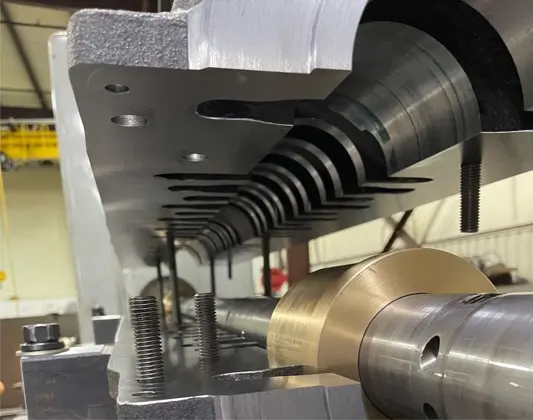

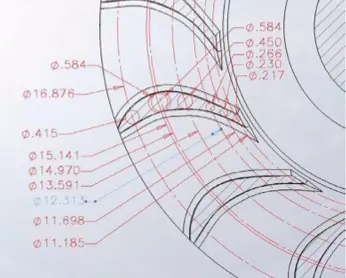

By cultivating strong relationships with local foundries, Hydro Parts Solutions can provide expedited lead times while maintaining control of product quality throughout the manufacturing process. They adhere to strict process control procedures, including providing standardized parts numbers and generating drawings for every part.

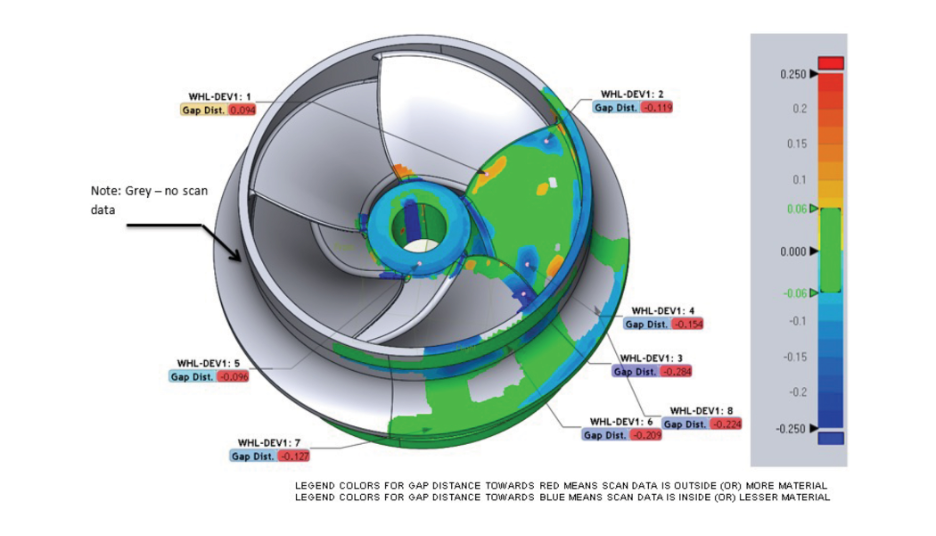

By cultivating strong relationships with local foundries, Hydro Parts Solutions can provide expedited lead times while maintaining control of product quality throughout the manufacturing process. They adhere to strict process control procedures, including providing standardized parts numbers and generating drawings for every part. As pump experts, Hydro has the experience to reverse engineer and supply complex hydraulic components and the resources to diagnose design problems and suggest targeted upgrades. Hydro routinely upgrades vintage equipment with proven design component design upgrades that counteract known failure modes. Our global engineering team works closely with our parts division to perform hydraulic modifications that increase efficiency or help end users meet changed system requirements.

As pump experts, Hydro has the experience to reverse engineer and supply complex hydraulic components and the resources to diagnose design problems and suggest targeted upgrades. Hydro routinely upgrades vintage equipment with proven design component design upgrades that counteract known failure modes. Our global engineering team works closely with our parts division to perform hydraulic modifications that increase efficiency or help end users meet changed system requirements.