A nuclear power plant required field service support for their high energy multi-stage diffuser barrel pump when a feeler gage became lodged inside the pump element. The station had been experiencing a problem with a lube oil pump and the decision was made to flush the lube oil lines. During this process, the plant’s maintenance team recognized that the charge pump’s inboard pump bearing housing dowels had been bent and the rotor was not properly centered on the inboard end. As Murphy’s Law dictates, “anything that can go wrong, will go wrong”. While the rotor was being centered, a feeler gauge that had been left in the element broke off and became stuck in the inboard end at the first-stage wear ring between the inboard impeller shroud and cover wall.

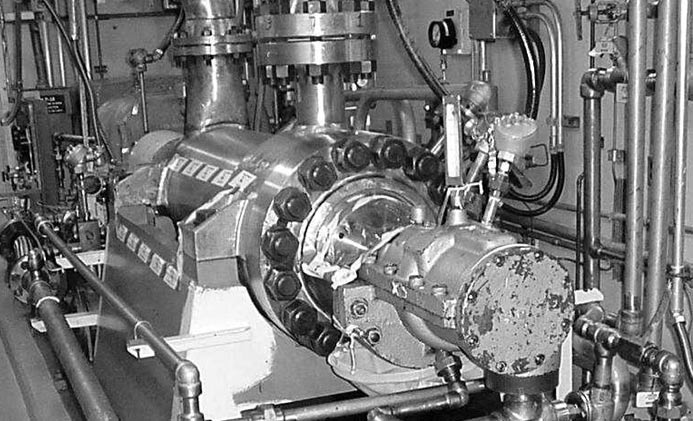

Picture above shows where feeler gage had become lodged in the element.

The rotor had shuttled and rotated a considerable amount during the original attempt to remove the broken remnant. The station contacted a reliable pump aftermarket service provider who had a highly-skilled field service team with the knowledge and experience to provide support. The station wanted to get this pump back online quickly and asked the field service team to work around the clock to retrieve the broken material and complete the pump assembly. The field service team collaborated with the station’s maintenance team to resolve the issues and get the pump back into service.

A bore scope was used to confirm the piece could not be easily extracted without removing the element. The Technical Field Advisor submitted to the station an Element Removal and Installation Procedure which defined the steps for retrieving the broken feeler gage and properly installing the element back into the barrel. Upon approval of the procedure, day and night shifts were scheduled to resolve the issues.

Resolving the Issues

An element skid was installed and scaffolding was erected in preparation for the removal of the element. The element was rigged, removed from the barrel to the skid, washed with demineralized water and wrapped. Then the element was rotated approximately 90-degrees for access to the rail key and cap screws. The rail key setscrews were removed and the key back tapped to allow for removal of the suction spacer. The suction spacer was a clearance fit to the intermediate cover, so heating was not required. The suction spacer was removed and the remnant was located in the diffuser vane. The remnant had made it past the impeller shroud to the diffuser vane as a result of shuttling and turning the rotor during initial removal attempts. Once dislodged, the maintenance teams agreed the geometry of the broken piece matched the end of the original feeler gage and everyone was confident there were no additional pieces left inside the element.

After masking for foreign material exclusion (FME), the first-stage impeller wear surface was polished in areas exhibiting localized galling which had been a result of normal wear and tear. The suction spacer, rail key, and rail key cap screws were reinstalled and the element was rotated so as to position the rail key back to the six o-clock position. Following FME inspection of the barrel, the Field Service team utilized the even pressure and positioning advantage of the discharge head to set the element into its register fit. Once the element was installed back into the barrel, the lube oil flush could be completed. The Field Service Technical Advisor assisted the station with the lube oil flush procedure.

Lessons Learned

The station personnel prevented a potentially serious situation by practicing STAR (Stop Think Act Review) and by having a “Questioning Attitude”. Their choice to bring in a highly-skilled field service team helped correct the problem in a fast and efficient manner.

Because maintenance teams often work on a variety of equipment, there are situations where specialists who are experts for specific kinds of equipment need to be onsite to provide support. It can be beneficial to have a Technical Field Advisor onsite to support your pump projects, especially during emergency outages.

Seasoned field advisors can also take the time to review existing procedures and can even help to improve them to ensure a successful removal and installation. Onsite pump support further provides confidence and instills peace of mind in the workforce.

Typical barrel pump used in high-pressure feedwater services.

John Neely, who has over 40 years experience working with pumps made by most major manufacturers, is the general manager for HydroAire Field Service, a division of HydroAire Inc. that provides comprehensive field service and turnkey support to pump users nationwide.

Download 10 Tips for Managing a Successful Field Service Project or call Tom Angerman at 800-223-7867 for information on Hydro’s comprehensive field services.