In the intricate world of industrial operations, pumps play a pivotal role. When a pump fails, it can disrupt entire production lines, leading to significant financial losses and safety hazards. Regardless of the quality of equipment construction or refurbishment, a proper field installation is critical to ensure reliable performance and achieve maximum life.

Unfortunately, the industrial sector is currently facing a significant challenge: the retirement of a large cohort of experienced workers. This exodus has created a skills gap, particularly in areas like field service. The expertise and knowledge these seasoned professionals possess are invaluable, and their absence can leave companies vulnerable.

That’s why partnering with a skilled and experienced field service team is critical.

Hydro’s field service technicians and technical field advisors (TFA) are highly knowledgeable professionals with experience over a wide range of pump applications, manufacturers, and models. This experience is a critical factor in ensuring that field projects are performed effectively:

- Hydro’s technicians are pump subject matter experts and have an extensive understanding of pump systems, their components, and common issues. This knowledge allows them to diagnose problems quickly and accurately.

- Experience has provided our field service technicians with the ability to think quickly on their feet and develop exceptional problem-solving skills. They can handle unexpected challenges, devise creative solutions, and minimize downtime.

- Experienced technicians are more efficient at their tasks. They know the best practices, processes, and tools to use, resulting in faster turnaround times without compromising the accuracy or quality of the field activity.

At Hydro, our on-site services team is comprised of subject matter experts in their field. Their knowledge across OEMs and industries is combined with Hydro’s extensive library historical data and global engineering support. It is also augmented by our field engineering division, which provides on-site performance and mechanical testing and troubleshooting. This powerful combination allows us to provide tailored solutions for your pump problems, enhance your reliability, and reduce your pump-related operating and maintenance costs.

Meet Hydro’s Technical Field Advisors:

Our Field Service Offerings

Hydro’s comprehensive field service offerings include:

- Installation and start-up

- Field machining and onsite welding

- Turnkey services

- Project management

- Vibration analysis

- Laser alignment

- Pump system troubleshooting

- Field engineering

- Emergency field response

- Hands-on training

Read more about how Hydro’s On-Site Services team has supported end user’s in the field with this case study from the Nuclear Power industry.

Contact us to discuss scheduling on-site support.

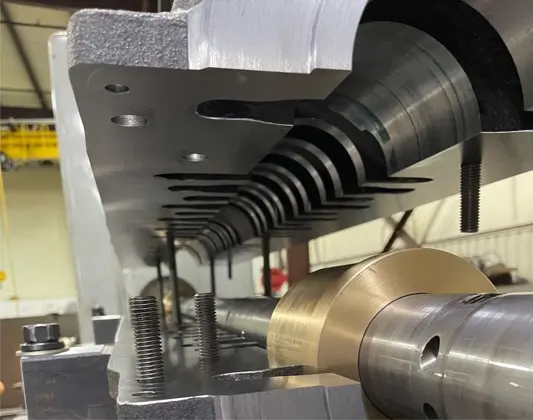

By cultivating strong relationships with local foundries, Hydro Parts Solutions can provide expedited lead times while maintaining control of product quality throughout the manufacturing process. They adhere to strict process control procedures, including providing standardized parts numbers and generating drawings for every part.

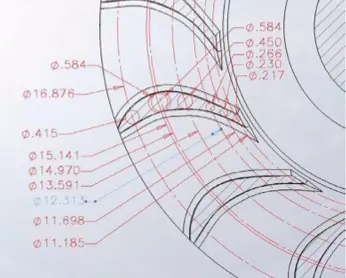

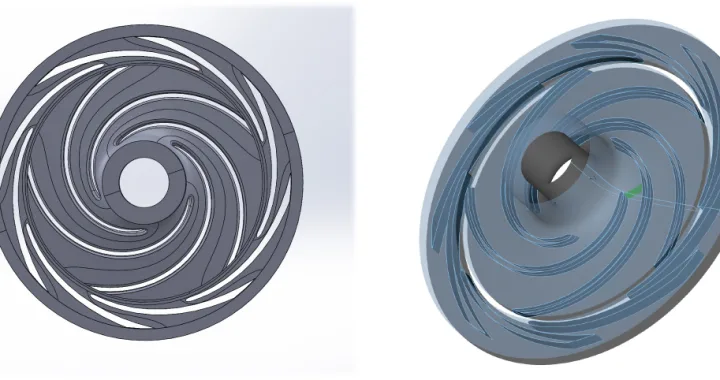

By cultivating strong relationships with local foundries, Hydro Parts Solutions can provide expedited lead times while maintaining control of product quality throughout the manufacturing process. They adhere to strict process control procedures, including providing standardized parts numbers and generating drawings for every part. As pump experts, Hydro has the experience to reverse engineer and supply complex hydraulic components and the resources to diagnose design problems and suggest targeted upgrades. Hydro routinely upgrades vintage equipment with proven design component design upgrades that counteract known failure modes. Our global engineering team works closely with our parts division to perform hydraulic modifications that increase efficiency or help end users meet changed system requirements.

As pump experts, Hydro has the experience to reverse engineer and supply complex hydraulic components and the resources to diagnose design problems and suggest targeted upgrades. Hydro routinely upgrades vintage equipment with proven design component design upgrades that counteract known failure modes. Our global engineering team works closely with our parts division to perform hydraulic modifications that increase efficiency or help end users meet changed system requirements.

To maintain safe, reliable and cost-effective operation, it is important to ensure pump systems are optimized. When approached with the need to optimize a pump system, many end users will look to purchase new equipment for the changed demand. This can be a costly and time-intensive endeavor, as new equipment installation is often accompanied by baseplate and piping modifications that require the system to be taken offline. In contrast, modifying the existing equipment to meet the new system needs provides a custom solution that maintains the original footprint, can be completed on a more aggressive timeline and often provides a more custom fit to the system.

To maintain safe, reliable and cost-effective operation, it is important to ensure pump systems are optimized. When approached with the need to optimize a pump system, many end users will look to purchase new equipment for the changed demand. This can be a costly and time-intensive endeavor, as new equipment installation is often accompanied by baseplate and piping modifications that require the system to be taken offline. In contrast, modifying the existing equipment to meet the new system needs provides a custom solution that maintains the original footprint, can be completed on a more aggressive timeline and often provides a more custom fit to the system.