Many industries are facing a difficult situation as they struggle to maintain operational excellence of an aging asset base. The difficulties that come with older equipment have been aggravated by a loss of institutional knowledge that accompanies the mass retirement of an aging workforce.

In today’s competitive work environment, new talent with experience in the field is difficult to attract and retain. This often leads to a reduction in employee number and employee specialization; workers are taking on greater and increasingly diverse responsibilities with little time to focus beyond immediate needs. The lack of resources and knowledge has made the development of long-term proactive strategies extremely difficult.

The fundamental trend away from abundant, qualified talent is the underlying source of increases in maintenance costs, unexpected downtime events, more rework, longer cycle time for solving failures, and other problems that are negatively affecting plant profitability.

One solution is workforce training to replenish and even increase the essential knowledge necessary to effectively operate at acceptable profit margins. Customary training however will not achieve desired results for the following reasons:

-

- The training material does not fully address the workforce requirements for satisfactory job performance

- Retention of information provided in the classroom is extremely low leading to uncertainty and errors when engineers are challenged with solving specific site issues or technicians are executing routine maintenance activities

- The required information and/or process is not available at time of need

- The required information is not formatted consistent with the visual digital world of the new-age employee

- The workers trained are no longer employed, have been reassigned to other job responsibilities, or are not actively engaged in the required task.

Providing a Sound Foundation

The first step in developing a successful training program is ensuring that the material being presented is aligned with the daily job responsibilities of those being trained. Many training classes provided by OEMs are focused on the selection and application of their various products. While important for those who are purchasing new equipment, this does not address the many needs associated with operating, maintaining, and troubleshooting existing equipment.

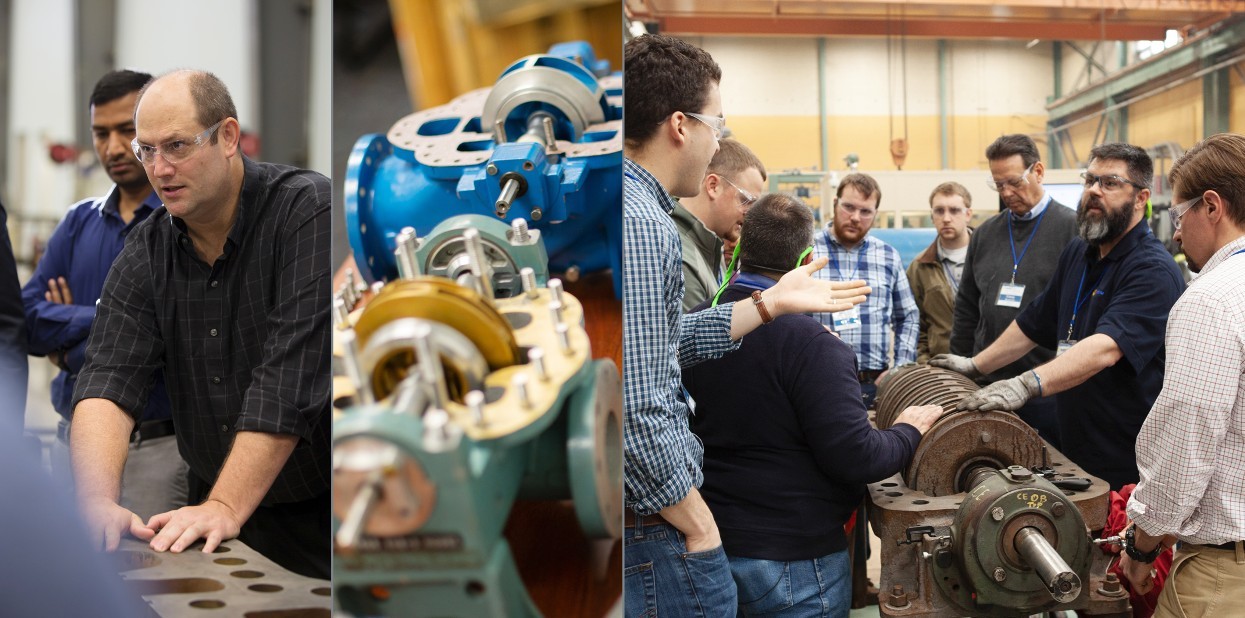

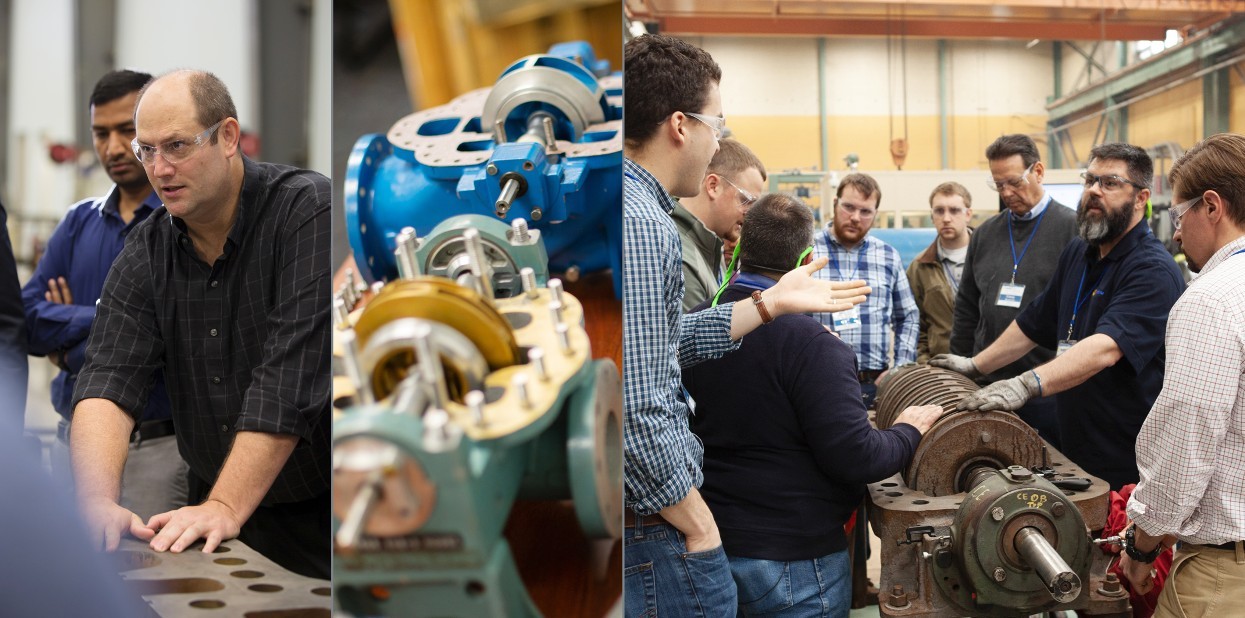

Training should provide a foundation of knowledge directly associated with the skills they need in their role. For engineers, this includes focus areas such as vibration fundamentals, failure modes organized by equipment type and observed condition, system assessment, and energy savings. Engineer training should (1) provide a base of knowledge to more effectively and efficiently perform their job function and (2) provide familiarity with internal and external resources available to supplement their own capabilities during troubleshooting and analysis. For maintenance professionals, training should focus on the form, fit, and function of components and best practices for inspection and maintenance of equipment; wherever possible, maintenance training should incorporate hands-on skill development.

Just-In-Time Resources

Even when the material being presented is directly applicable to the trainee’s job function and includes hands-on instruction, material retention is still a pervasive problem. Studies have shown that, on average, only 10% of classroom material is retained a week after the training is concluded. With this in mind, what options are available to ensure that foundational training provides the intended benefit?

Making training resources available for continuous reinforcement and just-in-time training will extend the benefit of classroom training and bolster material retention. Providing access to recordings of the training material and supplemental material for further enrichment will allow trainees to continue to engage with the material. It will also allow review of any relevant information as needed when problems arise.

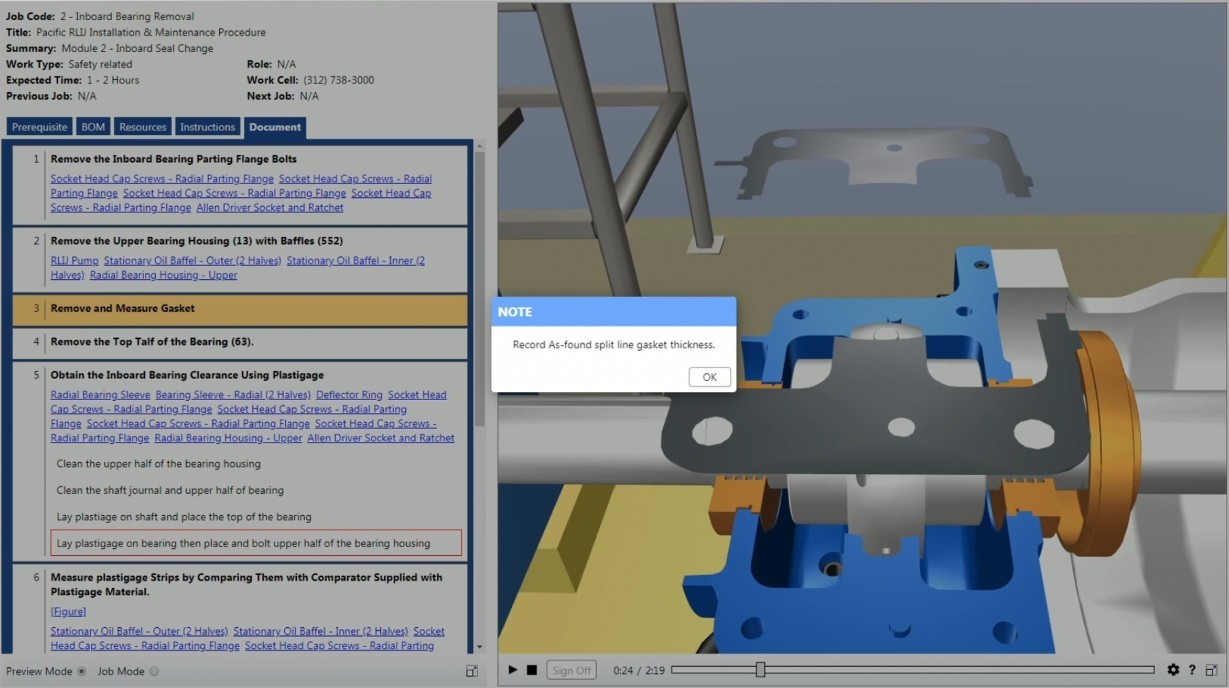

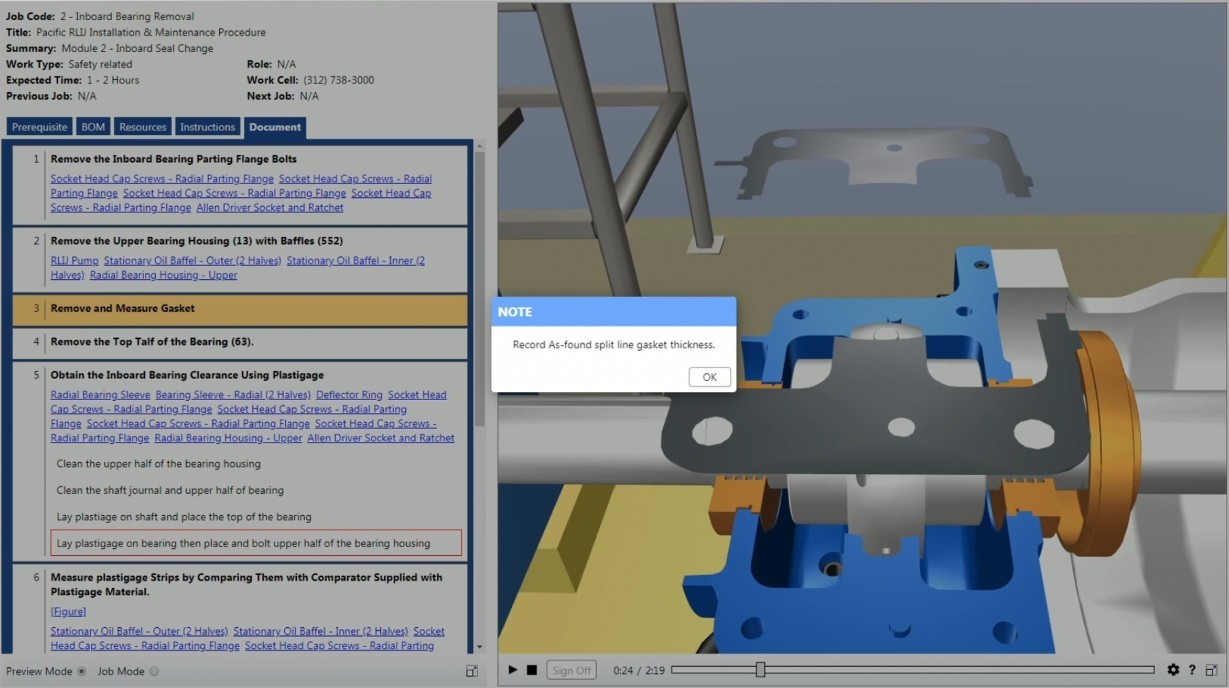

To support a reduction in maintenance errors, a review of existing procedures should be undertaken in tandem with the classroom training. This review will ensure that best practices taught in training are in alignment with site material. Upgrading existing procedures to include illustrations or animations of critical steps can also significantly improve work performance.

For training in any department, providing training resources in a digital format is essential. Digital resources introduce the material in a format that matches the learning style of the new generation of workers and offers interactivity and self-pacing.

Increasing Retention

The final piece of a successful training strategy focuses on application of the learned information. Facilitating use of the training material in the real world will greatly increase retention and identify areas where the trainee has questions or needs more clarity.

Applying knowledge in the field by instituting a mentorship program with internal and external subject matter experts not only supports material retention, it also supports worker retention. Mentorship programs communicate that the company is investing time and resources in worker development, help workers go beyond “putting out fires” to solve real problems, and deepen employees’ relationships within the company.

Ready to institute a successful training partnership? As an unbiased expert in the pump aftermarket, Hydro has developed training resources that range from single classes to long-term training partnerships. To learn more, read about Hydro University or browse our schedule of upcoming seminars and webinars.

Note: This article was originally published as a native ad with BIC.