Maintenance documentation varies widely in quality, often being incomplete, vague, or outdated. Procedures may lack detail, rely on obsolete methods, or feature unclear diagrams. Sometimes these procedures are taken from OEM manuals, which are too generic and require design knowledge to understand which steps are applicable.

For many years, maintenance crews have been relying on the experience of their workforce to perform the work correctly despite poor instructions. However, mass retirement from an aging workforce, higher employee turnover rates, and leaner staffs have taken away this safety net of experience and leave our facilities at risk. One of the greatest risks to the safe and profitable operation of our plants is preventable errors that result in online equipment failure.

A maintenance procedure that is optimized for the world we live in now has different requirements than the procedures developed in the past. Firstly, it needs to adequately capture the institutional knowledge of skilled professionals who are familiar with the equipment. Secondly, it needs to clearly illustrate each step in the procedure in a way that is easy to follow. Thirdly, it needs to accurately reproduce the design of the installed equipment instead of being overly generic. Lastly, it needs to be delivered in a format that reflects how the new generation of workers consume information- digital and interactive.

The last requirement may seem like more of a ‘want’ than a ‘need,’ but it is just as critical as the other three. Most workers who have graduated in the past 10-15 years are what are commonly referred to as ‘digital natives’ and have been immersed in a learning environment that depends heavily on digital assets. Providing information in a way that is intuitive for them to use and matches the way they are used to interacting with information will help them retain that information and complete work more efficiently. This not only supports reducing risk for maintenance errors, it streamlines the work completed to save on labor hours needed for each job.

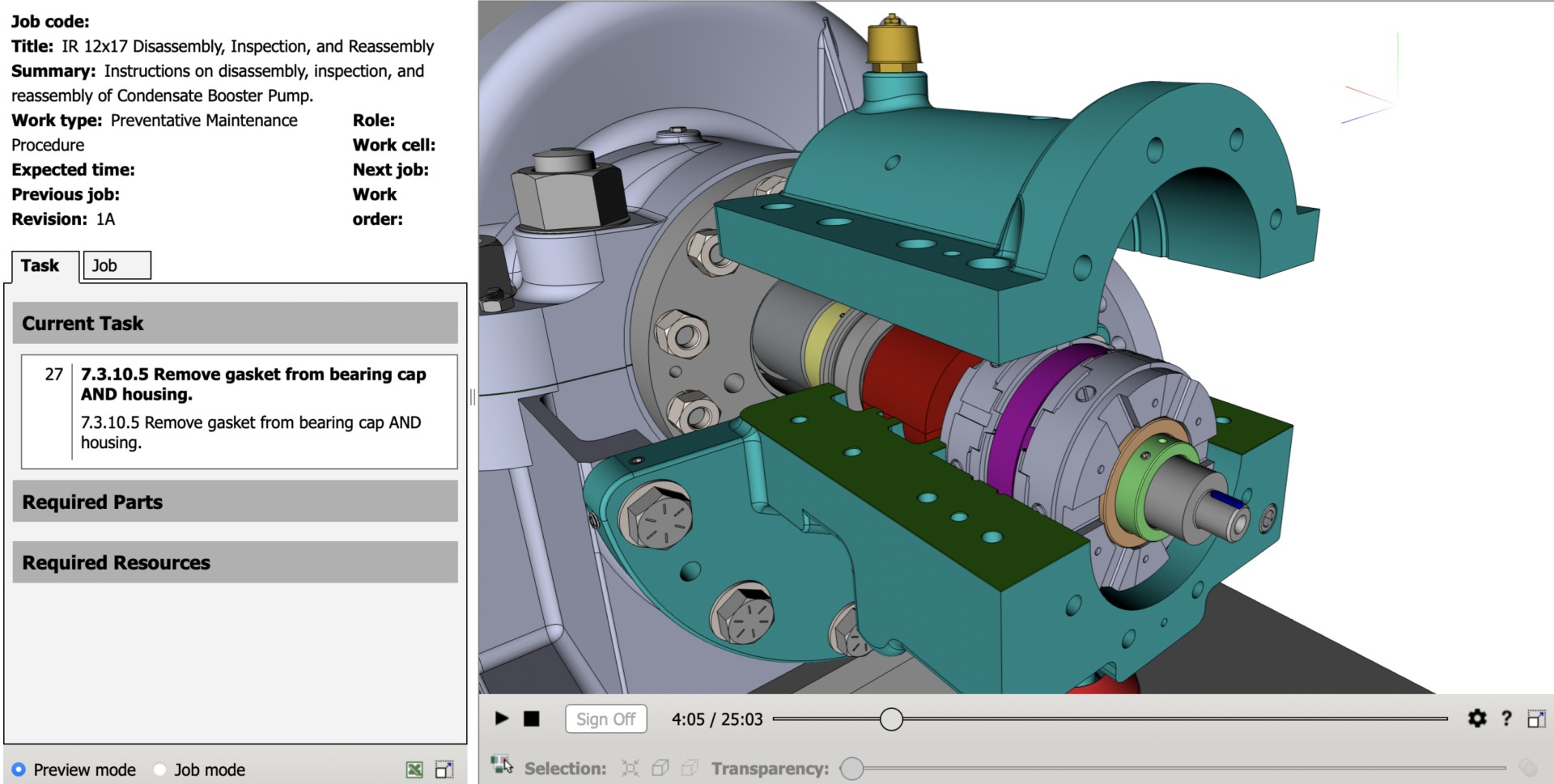

Hydro has addressed this need by developing IMPEL, an interactive, digital maintenance platform that replicates pump design and installation to clearly illustrate each step of the maintenance procedure. IMPEL uses an interactive 3D model of the equipment that is animated to illustrate each step of the maintenance procedure. Part of the development process includes an extensive overview of the procedure by Hydro’s experienced field service technicians to ensure that it includes best practices and to add notes and warnings into critical steps where mistakes may be made.

Introducing IMPEL from Hydro, Inc. on Vimeo.

Our maintenance professionals have a great responsibility- keeping our plants running safely and reliably. Let’s make sure they are armed with the best tools available.

Learn more about Hydro’s IMPEL or contact us for more information.

For those looking to engage in course material on their own schedule, Hydro University offers a breadth of online technical webinars and e-learning classes. The topics are expansive, covering a depth of knowledge such as centrifugal pump fundamentals, system optimization, vibration, failure modes, and many more.

For those looking to engage in course material on their own schedule, Hydro University offers a breadth of online technical webinars and e-learning classes. The topics are expansive, covering a depth of knowledge such as centrifugal pump fundamentals, system optimization, vibration, failure modes, and many more.

We agree with

We agree with

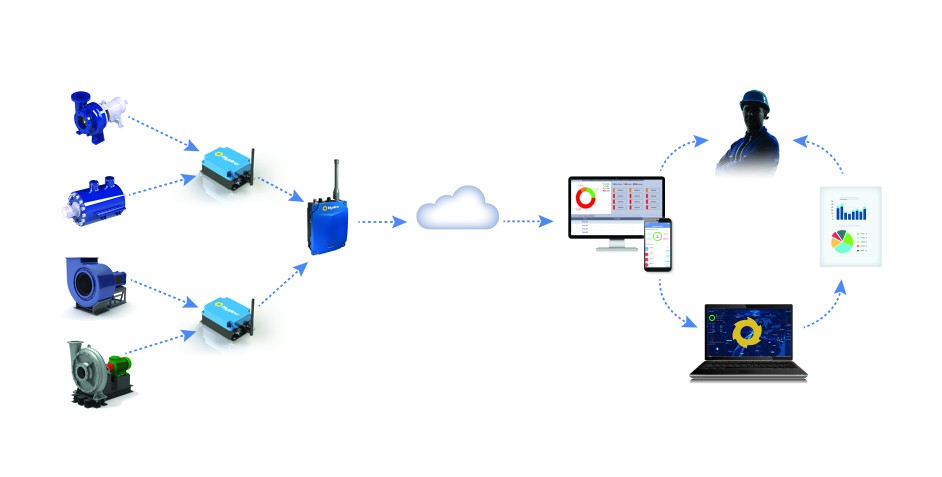

Ever wondered how to better understand equipment health but struggled with climbing the mountain of data available to come up with actionable information?

Ever wondered how to better understand equipment health but struggled with climbing the mountain of data available to come up with actionable information?