From lifting massive weights, to reverse engineering components with expansive surface areas, to troubleshooting vibration in machines susceptible to resonance problems, large vertical pumps have unique challenges. Fortunately, Hydro has cultivated specialized capabilities to meet these challenges.

From lifting massive weights, to reverse engineering components with expansive surface areas, to troubleshooting vibration in machines susceptible to resonance problems, large vertical pumps have unique challenges. Fortunately, Hydro has cultivated specialized capabilities to meet these challenges.

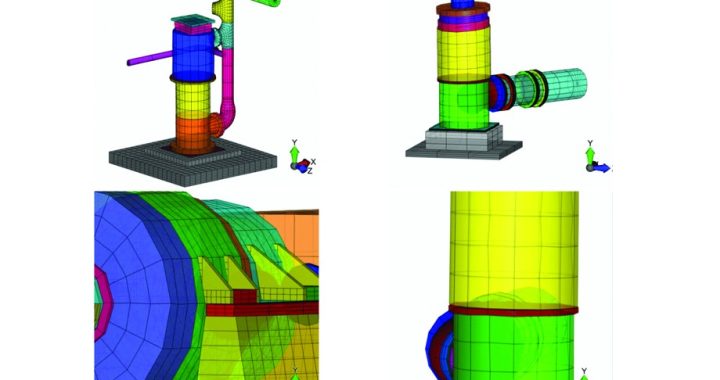

The first challenge is gathering dimensional data and providing reliable, quality parts supply. Large pumps are expensive to ship off-site and often run without a spare. Being able to capture precision measurements of critical parts on-site reduces both cost and risk. Hydro’s reverse engineering team is experienced in how to efficiently and accurately reverse engineer large components.

The field portion of the reverse engineering process for a large part can usually be accomplished in less than a day. After the measurements are taken, the pump can be returned to service while the model is completed and the part is manufactured.

Taking the initial component data is only the first step in Hydro’s reverse engineering process. Using their experience in the failure modes and upgrades of large pump designs, the reverse engineering team will recommend component upgrades or improved metallurgy to extend the life of the part. Where appropriate, they will also identify methods of refurbishment that can return a large part to reliable service in place of supplying a new component.

Another challenge when working on large pumps is that they require a shop with the appropriate tooling and lifting capacity. It also requires a team dedicated to providing a higher standard of repair. Because vertical pumps are made of several stacked components, maintaining tight tolerances and best-in-class fit-ups is critical for reliable operation. Hydro’s standards are more stringent than those required by any industry body. This translates to longer life, better performance, and safer operation.

Another challenge when working on large pumps is that they require a shop with the appropriate tooling and lifting capacity. It also requires a team dedicated to providing a higher standard of repair. Because vertical pumps are made of several stacked components, maintaining tight tolerances and best-in-class fit-ups is critical for reliable operation. Hydro’s standards are more stringent than those required by any industry body. This translates to longer life, better performance, and safer operation.

Learn more about our capabilities that support high capacity vertical pumps or contact us for more information.

From lifting massive weights, to reverse engineering components with expansive surface areas, to troubleshooting vibration in machines susceptible to resonance problems, large vertical pumps have unique challenges. Fortunately, Hydro has cultivated specialized capabilities to meet these challenges.

From lifting massive weights, to reverse engineering components with expansive surface areas, to troubleshooting vibration in machines susceptible to resonance problems, large vertical pumps have unique challenges. Fortunately, Hydro has cultivated specialized capabilities to meet these challenges. Another challenge when working on large pumps is that they require a shop with the appropriate tooling and lifting capacity. It also requires a team dedicated to providing a higher standard of repair. Because vertical pumps are made of several stacked components, maintaining tight tolerances and best-in-class fit-ups is critical for reliable operation. Hydro’s standards are more stringent than those required by any industry body. This translates to longer life, better performance, and safer operation.

Another challenge when working on large pumps is that they require a shop with the appropriate tooling and lifting capacity. It also requires a team dedicated to providing a higher standard of repair. Because vertical pumps are made of several stacked components, maintaining tight tolerances and best-in-class fit-ups is critical for reliable operation. Hydro’s standards are more stringent than those required by any industry body. This translates to longer life, better performance, and safer operation.