Performance testing in a controlled environment is an important tool for pump designers and users alike. Understanding how the pump will react hydraulically and mechanically throughout the full range of operation enables improved equipment reliability, optimized efficiency, and reduced operating and maintenance costs.

Performance testing in a controlled environment is an important tool for pump designers and users alike. Understanding how the pump will react hydraulically and mechanically throughout the full range of operation enables improved equipment reliability, optimized efficiency, and reduced operating and maintenance costs.

In the aftermarket, performance testing helps equipment owners:

- Identify discrepancies between actual and expected performance before equipment is returned to the field

- Validate acceptable mechanical performance of critical equipment post-repair- before significant damage occurs

- Confirm effectiveness of hydraulic modifications by validating that theoretical performance is accurate and repeatable

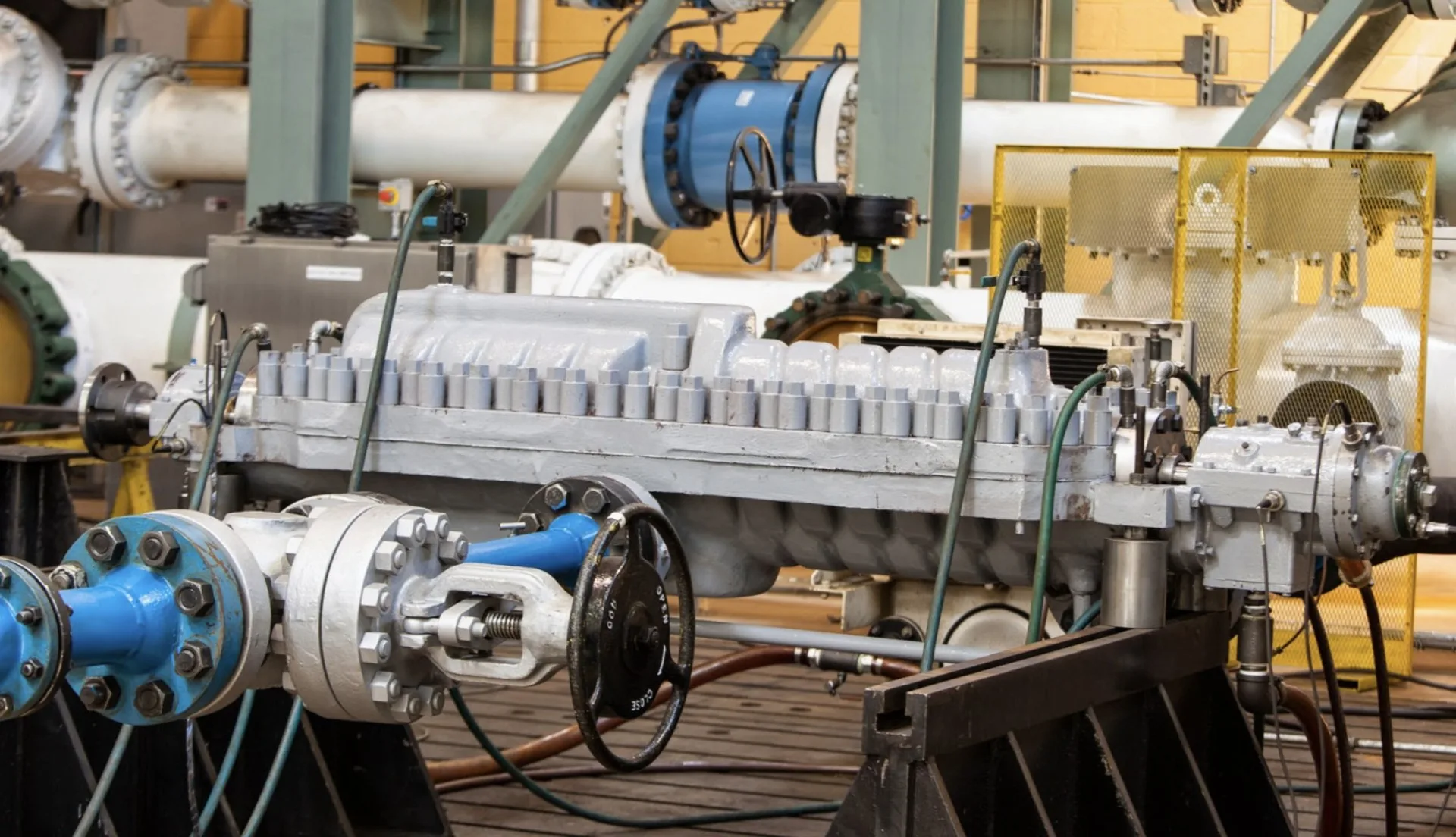

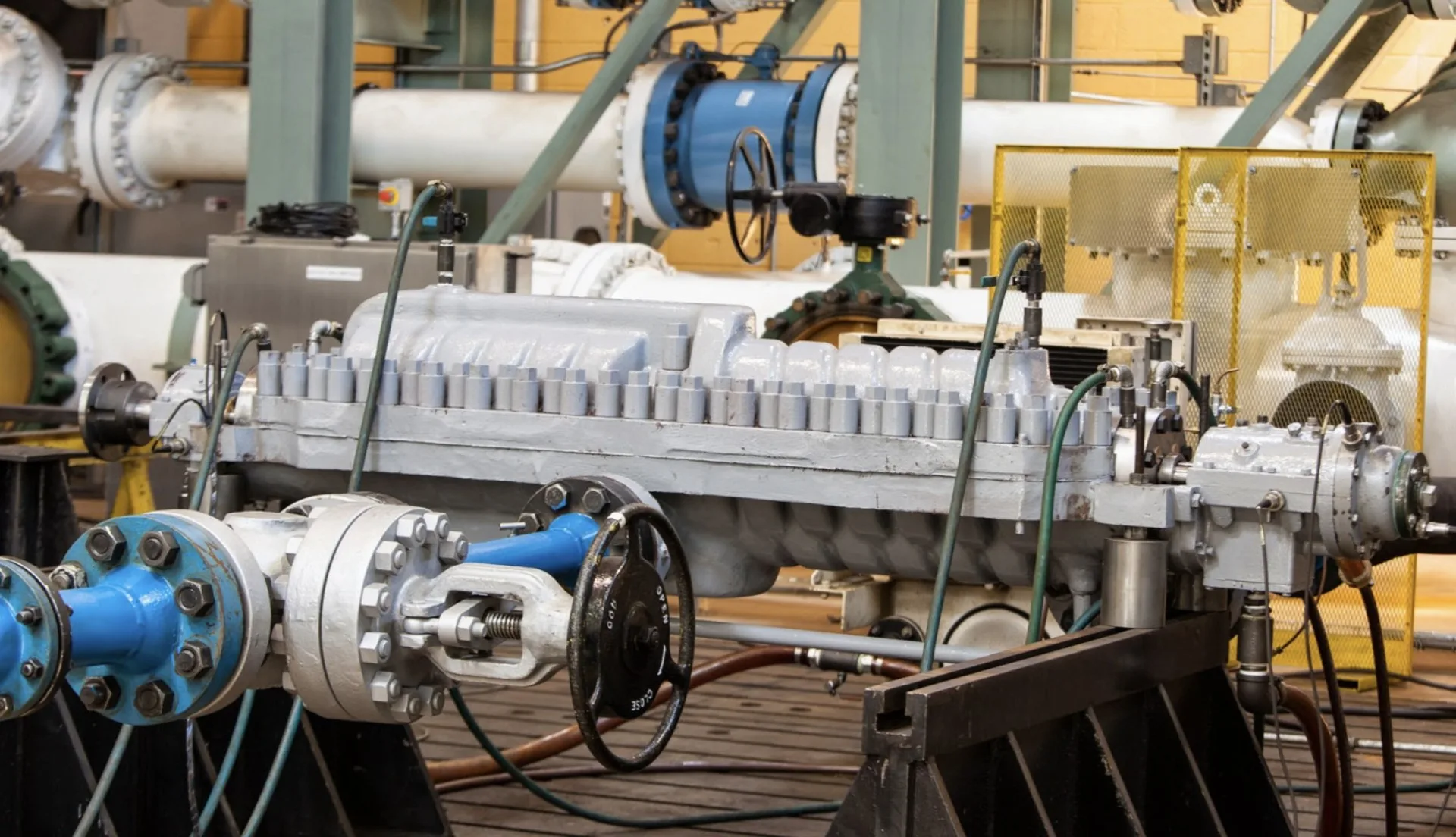

To support end users in understanding equipment health and performance, Hydro built its Certified Performance Test Lab at the HydroAire 40th Street service center in Chicago. Our test lab was the first to be certified by the Hydraulic Institute’s Pump Test Lab Approval Program, and all testing is completed in accordance with Hydraulic Institute (HI) 14.6/40.6 and/or API 610, ASME, or ISO, as relevant.

To support end users in understanding equipment health and performance, Hydro built its Certified Performance Test Lab at the HydroAire 40th Street service center in Chicago. Our test lab was the first to be certified by the Hydraulic Institute’s Pump Test Lab Approval Program, and all testing is completed in accordance with Hydraulic Institute (HI) 14.6/40.6 and/or API 610, ASME, or ISO, as relevant.

Hydro’s test lab is tailored to the demands of the aftermarket, focusing on flexibility and data transparency. Instead of moving the piping to the pump, Hydro’s Test Lab moves the pump to the piping:

- A 36’x20’ baseplate allows for quick and customized installation

- A multitude of piping inlets/outlets suitable for a wide range of nozzle sizes

- Accommodates hundreds of different pump configurations

- Allows multiple pumps to be staged for testing simultaneously

This flexible configuration enables Hydro to set the standard for turnaround times on aftermarket testing. In addition to common offerings such as hydraulic performance, mechanical performance, NPSH, endurance, and critical speed testing, Hydro has performed custom testing configurations to help end users understand specific problems. This is illustrated in the Test Lab’s inaugural test, which was a series of tests for a nuclear safety-related service to help an end user prove to the NRC that this service was capable of handling transient air voids in the system.

Learn more about Hydro’s Certified Performance Test Lab or contact us to schedule a pump test.

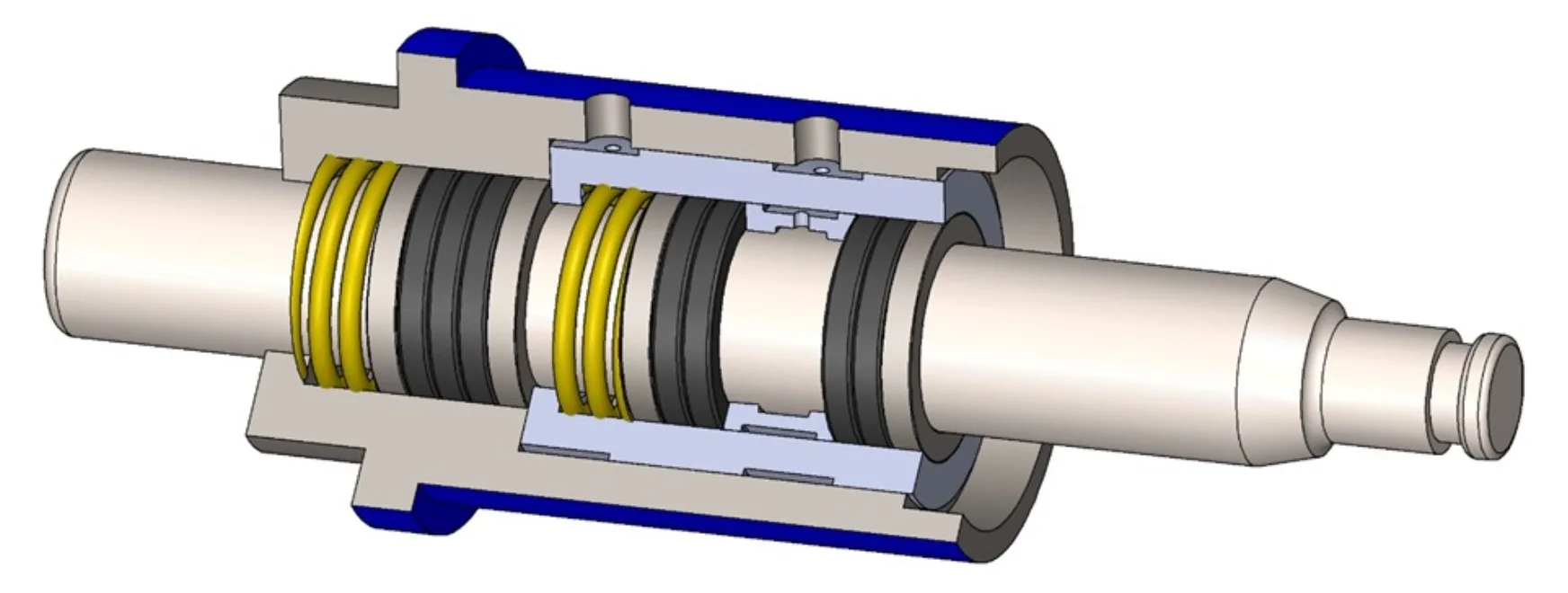

The successful operation of reciprocating power pumps hinges on a careful understanding of their sealing mechanisms and meticulous maintenance practices to ensure long-term reliability and minimal downtime.

The successful operation of reciprocating power pumps hinges on a careful understanding of their sealing mechanisms and meticulous maintenance practices to ensure long-term reliability and minimal downtime.

Performance testing in a controlled environment is an important tool for pump designers and users alike. Understanding how the pump will react hydraulically and mechanically throughout the full range of operation enables improved equipment reliability, optimized efficiency, and reduced operating and maintenance costs.

Performance testing in a controlled environment is an important tool for pump designers and users alike. Understanding how the pump will react hydraulically and mechanically throughout the full range of operation enables improved equipment reliability, optimized efficiency, and reduced operating and maintenance costs. To support end users in understanding equipment health and performance, Hydro built its Certified Performance Test Lab at the HydroAire 40th Street service center in Chicago. Our test lab was the first to be certified by the Hydraulic Institute’s

To support end users in understanding equipment health and performance, Hydro built its Certified Performance Test Lab at the HydroAire 40th Street service center in Chicago. Our test lab was the first to be certified by the Hydraulic Institute’s

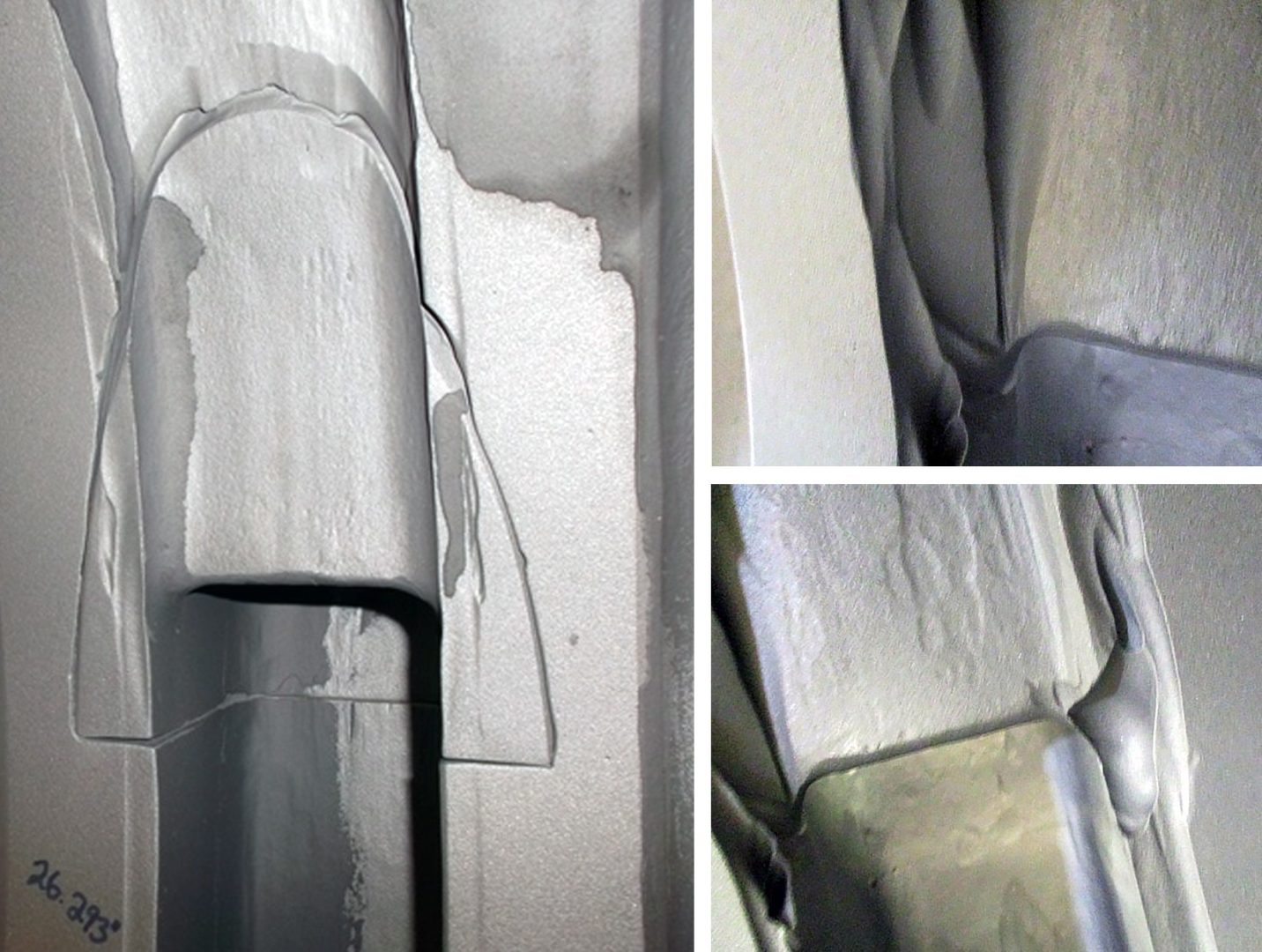

Many of our aging facilities are still using the pumps that were purchased and commissioned during plant construction. Despite the age of this equipment, effective maintenance strategies and upgrade opportunities can extend useful life for decades more. Older pumps are often more robust than current designs, which take advantage of new manufacturing technologies to reduce the raw materials needed for construction. However, vintage equipment has its downfalls as well. It is important to understand the challenges we face when operating and maintaining vintage equipment so that we can stay ahead of potential sources for decreased reliability.

Many of our aging facilities are still using the pumps that were purchased and commissioned during plant construction. Despite the age of this equipment, effective maintenance strategies and upgrade opportunities can extend useful life for decades more. Older pumps are often more robust than current designs, which take advantage of new manufacturing technologies to reduce the raw materials needed for construction. However, vintage equipment has its downfalls as well. It is important to understand the challenges we face when operating and maintaining vintage equipment so that we can stay ahead of potential sources for decreased reliability.