A nuclear utility had been observing axial shuttling on their three single stage, double suction Condensate Booster pumps. To better understand the circumstances driving this phenomenon, they asked Hydro Reliability Services to provide in-depth field testing of the equipment at different operating loads.

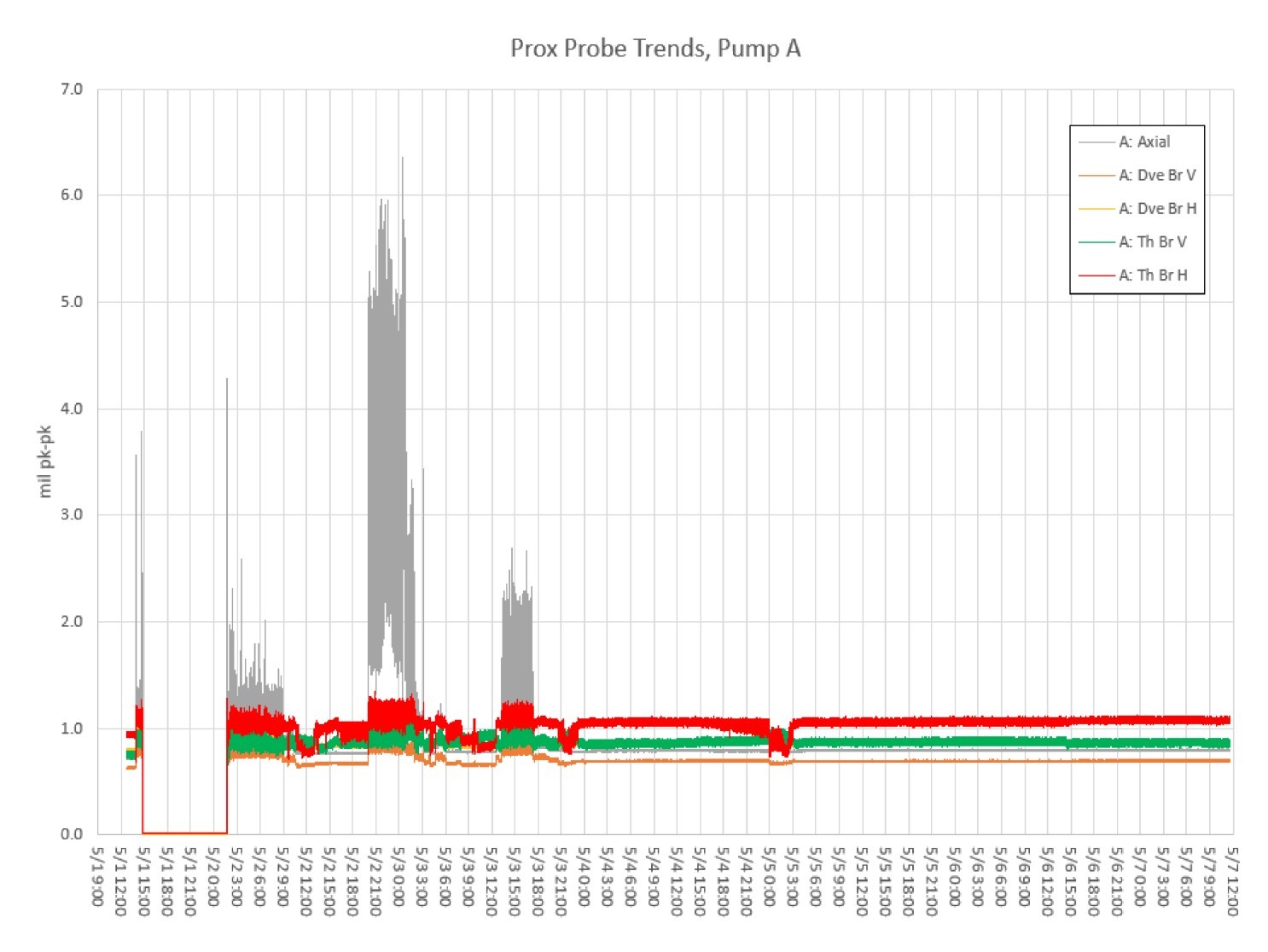

Evaluation of the vibration performance took place over the course of six days, in which data was recorded from the startup of the plant through to full unit load. To properly identify and understand the axial shuttling described by site personnel, the broad range of data was studied and fifteen individual data points more closely examined.

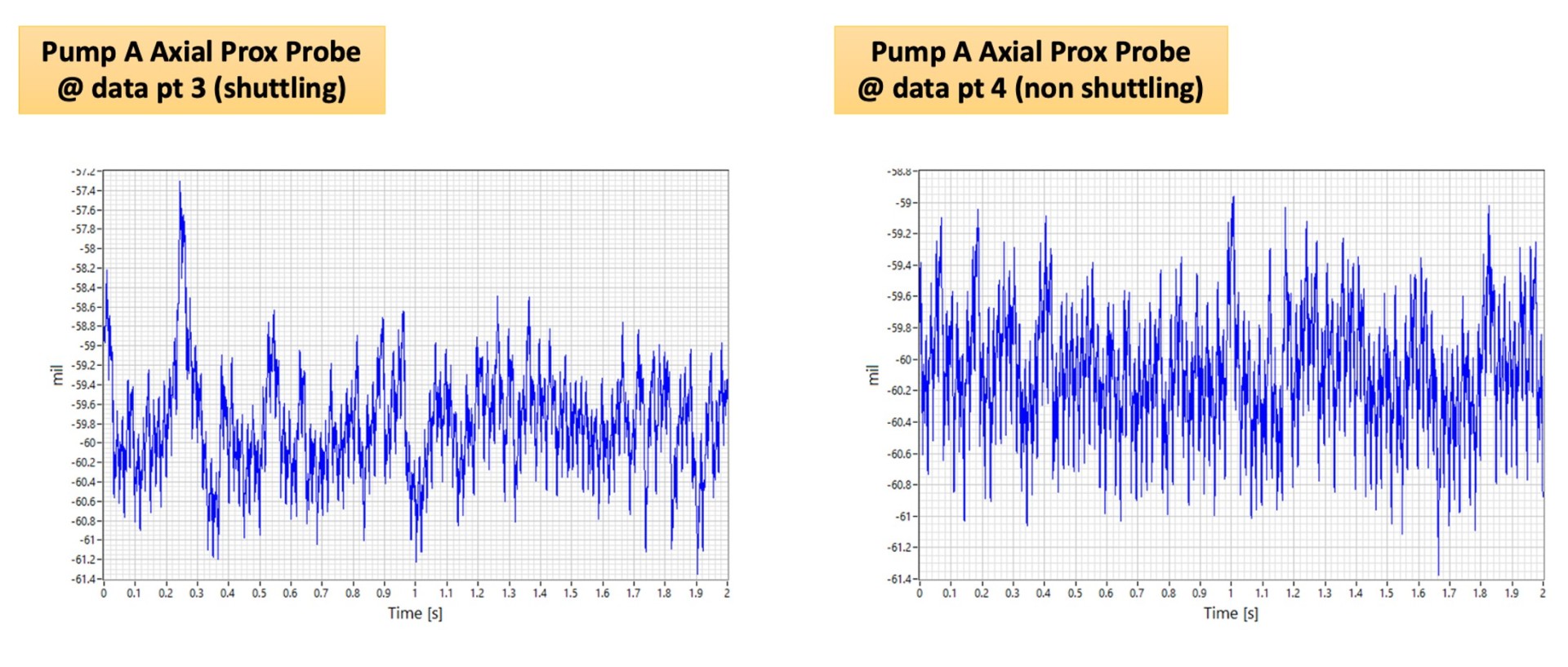

Axial shuttling is observed in proximity probe data to be a sub-synchronous event with non-periodic perturbations (spikes) occurring at low frequency. These perturbations are not present in radial channels and spectra of radial channels do not show sub-synchronous excitation.

The field data taken shows that axial shuttling occurs in cases where the flow rate is below 70% of the rated flow and occurs most frequently and with a higher incipient flow rate in Pump A. For pumps B and C, the axial shuttling was not as widely observed and only occurred in the lowest flow rate scenarios, where the flow was less than 55% of the rated flow.

It was determined that the axial shutting could not be detected in the bearing housing vibration, only the rotor vibration, and does not appear to negatively impact hydraulic performance. However, it is very likely that prolonged operation with axial shuttling will reduce the life of the pumps, motors, and mechanical seals.

Understanding which pumps are more susceptible to axial shuttling and under what operating conditions helps the plant to assess the combination of pumps working in parallel for different operating modes. Knowing that Pump A is more prone to axial shuttling and will exhibit thrust reversals at a higher flow rate gives an important insight into how to operate the system more reliably.