One of the most persistent challenges in condition monitoring and vibration analysis is not finding signals. Modern wireless condition monitoring systems are excellent at that. The harder problem is understanding what those signals actually mean within the context of rotating equipment dynamics.

We recently evaluated a pump at a midstream facility where industrial vibration analysis showed vibration levels increasing sharply as operating speed approached roughly 1125 rpm. The frequency spectrum made the issue immediately visible. A dominant 10× running speed harmonic emerged, then largely disappeared as speed moved away from that range.

At first glance, the solution seems obvious. Avoid that speed.

In midstream operations, however, it is rarely that simple. Flow requirements, fluid properties, and system demand often dictate operating speeds. Blocking off ranges in a variable frequency drive (VFD) is not always practical, and in many cases, not possible at all.

That is where the real work begins.

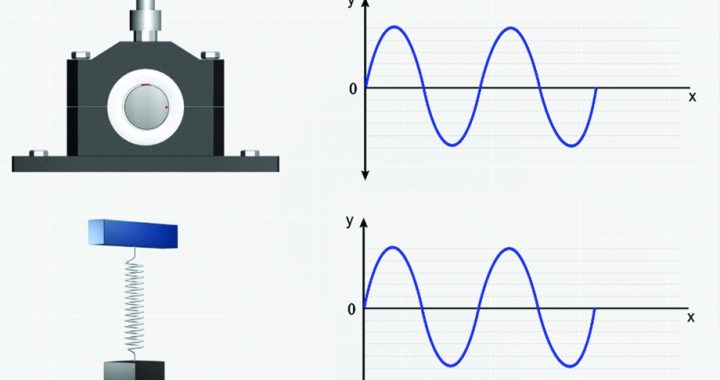

The challenge was not detecting vibration. It was determining when a structural resonance was actually being excited, how strong the response was across speed and load, and what that meant for bearings, seals, and the overall machine train over time. Without that engineering context, the signal alone is easy to misinterpret.

When we analyzed the data across the full operating envelope, the picture became clearer. This was not a machine in distress. It was a predictable speed-dependent resonance that was only excited under very specific operating conditions.

That distinction matters, because it fundamentally changes the solution.

The answer is not simply “don’t run there.” The answer is engineering the system to shift the resonance, not forcing operations to work around it. That may involve stiffness changes, mass adjustments, or other design-level interventions that address the root cause rather than the symptom.

This is the gap between monitoring and reliability. Detecting issues is only the first step. Long-term reliability comes from engineering-led condition monitoring, where system behavior is understood and engineering judgment is applied to turn signals into meaningful decisions.

Seeing a signal is easy. Understanding it is harder. If you are wrestling with pump resonance, vibration behavior, or recurring condition monitoring alarms that never quite turn into answers, let’s talk.

In-depth field testing paired with computational analysis provides a clear path to both an accurate diagnosis and a solution that has a high likelihood of success. The effectiveness of this methodology was proven for a Gulf Coast midstream company who was experiencing high vibration with their vertical freshwater pumps. By applying advanced field diagnostics, the end user was able to understand the underlying causes of the vibration and evaluate possible solutions in a theoretical environment prior to implementing them in the field.

In-depth field testing paired with computational analysis provides a clear path to both an accurate diagnosis and a solution that has a high likelihood of success. The effectiveness of this methodology was proven for a Gulf Coast midstream company who was experiencing high vibration with their vertical freshwater pumps. By applying advanced field diagnostics, the end user was able to understand the underlying causes of the vibration and evaluate possible solutions in a theoretical environment prior to implementing them in the field.