Application: Make-Up Liquor

Pump Details: Ahlstrom Model 2LRS-20

Pump Type: 2-Stage Overhung

When a pulp mill’s make-up liquor pump failed, it was sent to Hydro’s Scotford facility for refurbishment and upgrade to restore reliability.

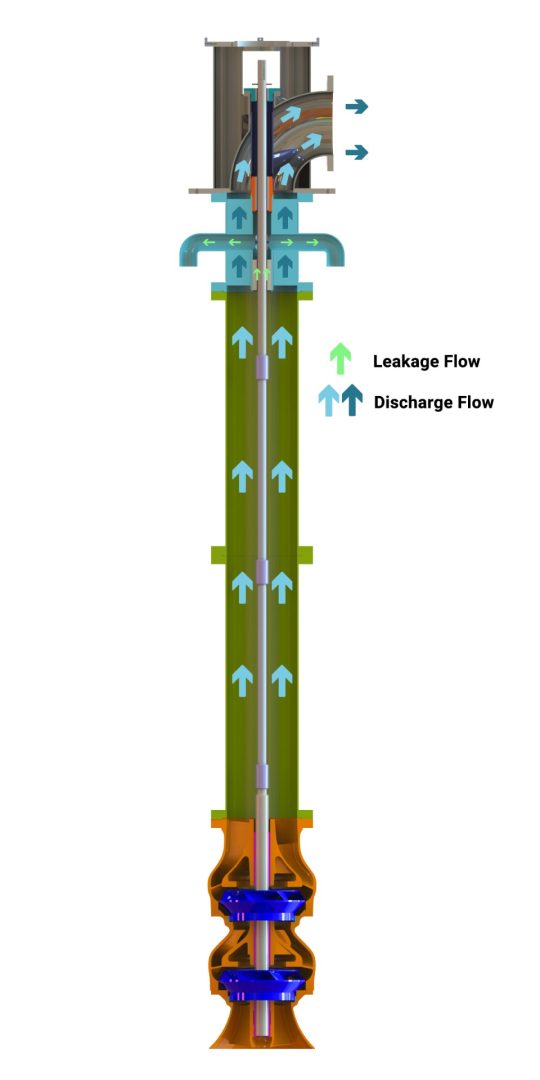

Hydro’s standard disassembly and inspection process uncovered a path for abrasives to reach the wear rings. Heavy localized wear was identified at the casing, behind the casing wear ring.

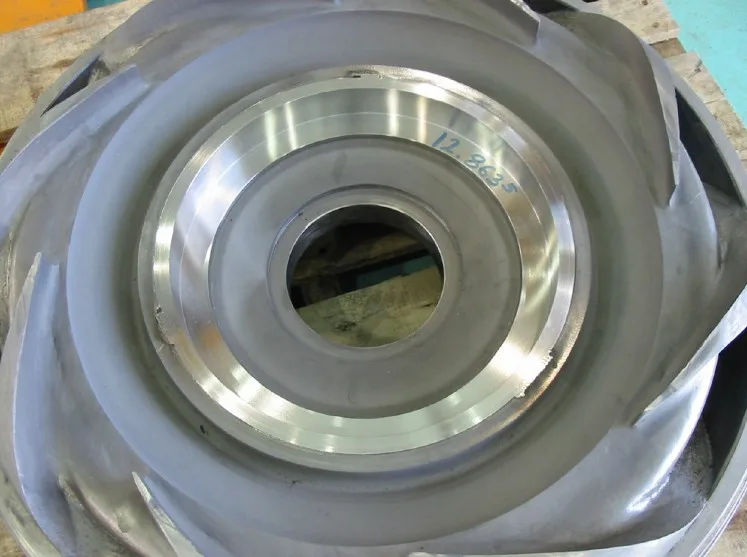

Additionally, the pump was experiencing excessive leakage of the seal water and black liquor. The millwrights were unable to properly adjust the packing gland because the 2-bolt packing gland follower was cocked on the studs due to the high pressure of the seal water. This misalignment also caused significant wear to the diffuser vane tips.

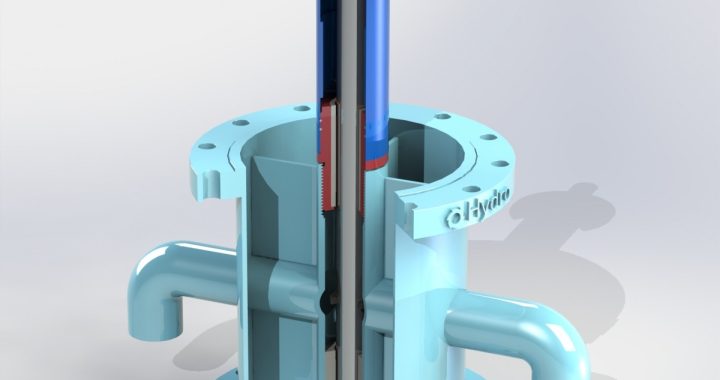

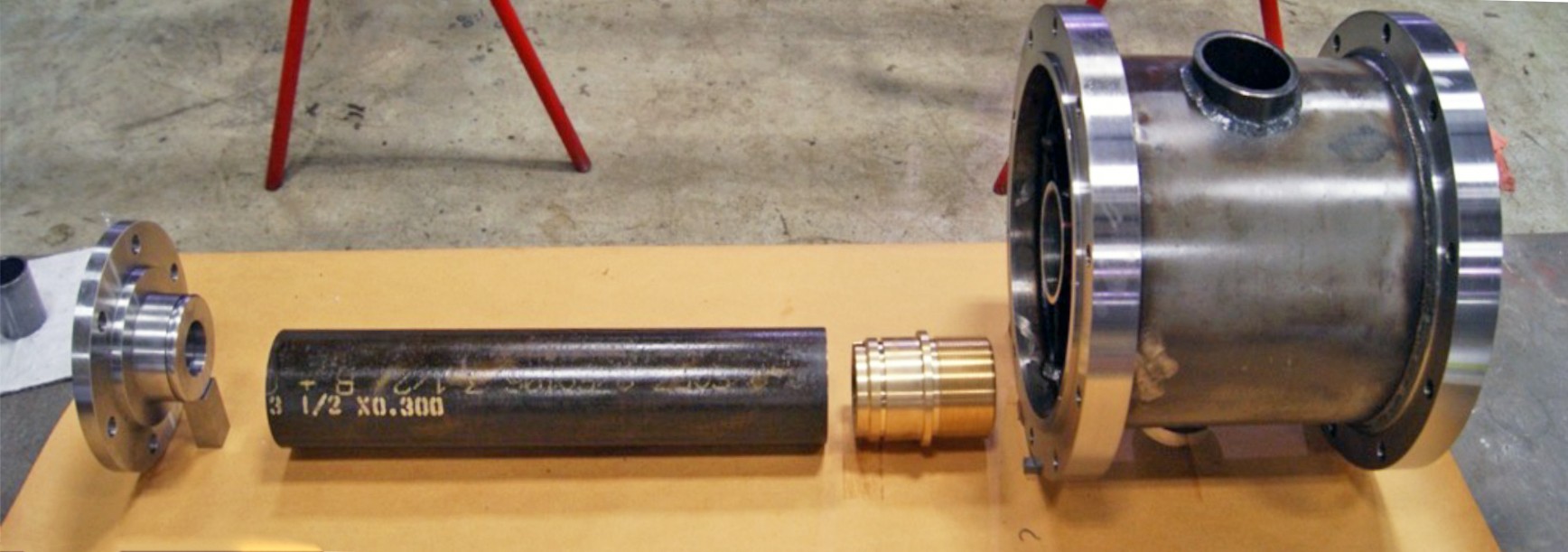

Hydro manufactured new wear rings without slots to prevent the abrasive material from damaging the case and minimize wear behind the casing wear rings. The worn areas of the casing and a new sleeve were overlaid with tungsten carbide to prevent further damage.

Hydro manufactured new wear rings without slots to prevent the abrasive material from damaging the case and minimize wear behind the casing wear rings. The worn areas of the casing and a new sleeve were overlaid with tungsten carbide to prevent further damage.

Hydro designed and machined a 4-bolt split packing gland follower to help maintain alignment of the packing gland follower with the stuffing box. A special material was installed to help cool and lubricate the seal to allow the proper distribution of seal water.

The diffuser vane tips were welded to restore them to their pre-wear length and the impellers were balanced to a stringent level of 2 W/N. The 2 stage pump was built vertically to ensure centerline compatibility of stationary components.

This engineered rebuild provided improved reliability for the makeup liquor pump.

Learn more about Hydro’s focused improvements for the pulp and paper industry here. Read more about Hydro Scotford here.