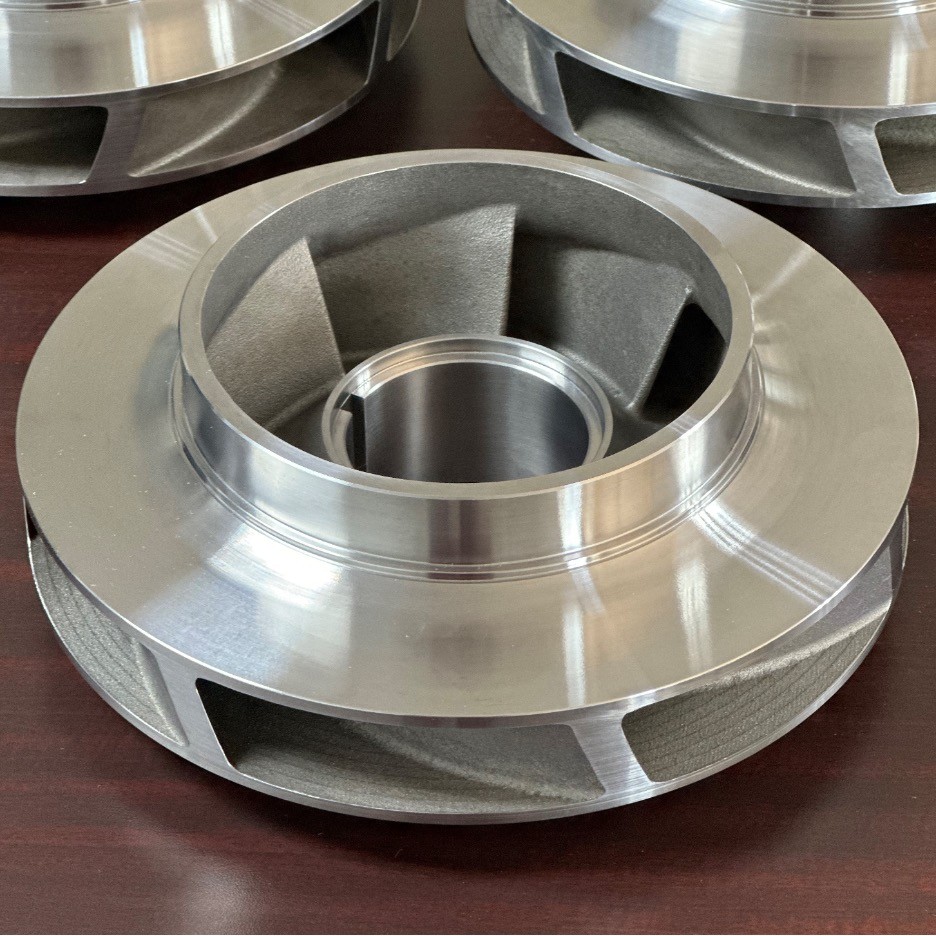

Hydro Parts Solutions recently manufactured three impellers for a rerate project being developed through Hydro’s Rocky Mountain service center in Denver, CO. Hydro Global Engineering determined the new hydraulic design for the rerated pump, which required modifications to the casing and new impellers.

Hydro Parts Solutions recently manufactured three impellers for a rerate project being developed through Hydro’s Rocky Mountain service center in Denver, CO. Hydro Global Engineering determined the new hydraulic design for the rerated pump, which required modifications to the casing and new impellers.

The end user chose to have the new impellers manufactured out of CA6NM using investment casting, which provides a smoother surface finish to slightly increase the impeller efficiency. Hydro Parts Solutions drove the project from casting package design through final machining, with the impellers being cast and finish-machined within 6 weeks.

The new pump design was successfully tested at Hydro’s performance test lab, validating the new hydraulics. The custom performance will help the midstream end user achieve their desired system flow with maximum reliability and minimum energy usage.

Explore Hydro Parts Solutions’ design process in this video case study.

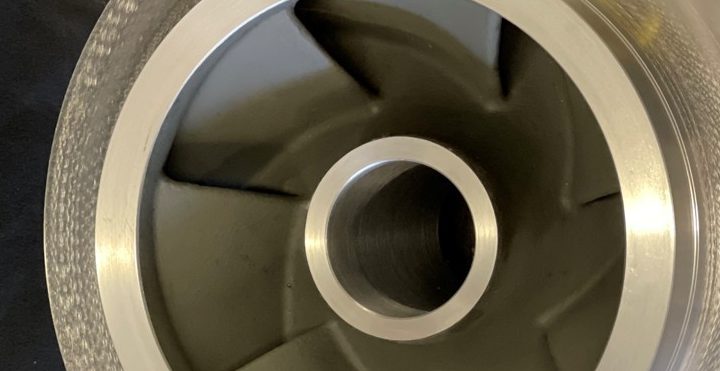

State of the Art Parts: Hydro Parts Solutions recently supplied a new impeller as part of a project to improve the operation of a pump that was not performing per the OEM curve. The first step in the process was reverse-engineering the used sample impellers. The reverse-engineered model was used by Hydro’s Global Engineering team to perform a computational fluid dynamics (CFD) analysis to determine the best possible hydraulic design for the plant’s expected operating range.

State of the Art Parts: Hydro Parts Solutions recently supplied a new impeller as part of a project to improve the operation of a pump that was not performing per the OEM curve. The first step in the process was reverse-engineering the used sample impellers. The reverse-engineered model was used by Hydro’s Global Engineering team to perform a computational fluid dynamics (CFD) analysis to determine the best possible hydraulic design for the plant’s expected operating range.