Did you know that Hydro can provide aftermarket parts solutions for critical pump parts and rotating equipment?

Hydro Parts Solutions, a subsidiary of Hydro, Inc., offers complex solutions to obsolescence as well as difficult-to-source replacement parts.

Utilizing state-of-the-art technology, such as laser scanning and 3D printing, Hydro Parts Solutions has established itself as a proven solution that possesses both the knowledge and sophisticated casting capabilities to expedite casting projects from months to weeks.

Types of items we can cast (and more):

- Impellers

- Diffusers

- Discharge Heads

- Casing Bowls

- Suction Bells

Hydro Parts Solutions supports emergency component replacements at an optimal time frame while reducing risk, operational downtime, and unforeseen costs.

Engineered Quality Parts – On Demand, delivering:

- Consistent Quality

- 3D Sand Printing

- Computer-aided machining

- Emergency Repair

- Industry Standards and Design Control Processes

- Short Turnaround

- Catalogue Data for Future Use

- Transparency and Communication for our Customers

Want to take a detailed look into our proven parts process? Click on the link to view our redesigned webpage: https://hydroinc.com/parts-solutions/

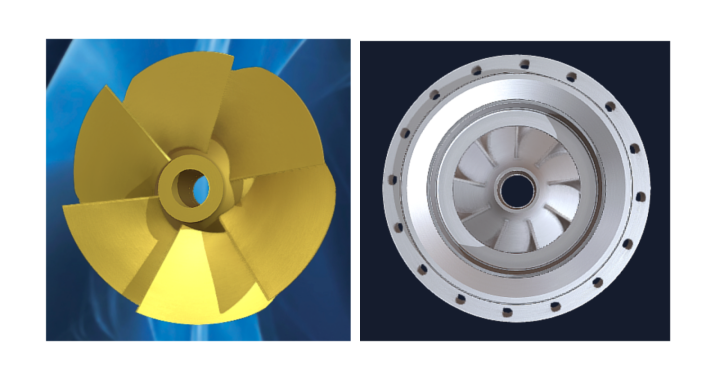

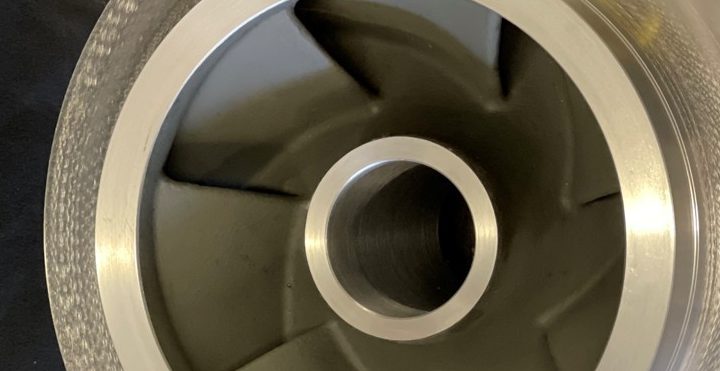

State of the Art Parts: Hydro Parts Solutions recently supplied a new impeller as part of a project to improve the operation of a pump that was not performing per the OEM curve. The first step in the process was reverse-engineering the used sample impellers. The reverse-engineered model was used by Hydro’s Global Engineering team to perform a computational fluid dynamics (CFD) analysis to determine the best possible hydraulic design for the plant’s expected operating range.

State of the Art Parts: Hydro Parts Solutions recently supplied a new impeller as part of a project to improve the operation of a pump that was not performing per the OEM curve. The first step in the process was reverse-engineering the used sample impellers. The reverse-engineered model was used by Hydro’s Global Engineering team to perform a computational fluid dynamics (CFD) analysis to determine the best possible hydraulic design for the plant’s expected operating range.

The OEM had provided a minimum delivery time of 10-12 weeks for both parts. Because these parts were necessary for the equipment to be returned to service, the customer sought out a qualified vendor who could provide the components in a shorter turnaround time. Hydro Parts Solutions was able to offer a 5-6 week delivery.

The OEM had provided a minimum delivery time of 10-12 weeks for both parts. Because these parts were necessary for the equipment to be returned to service, the customer sought out a qualified vendor who could provide the components in a shorter turnaround time. Hydro Parts Solutions was able to offer a 5-6 week delivery.