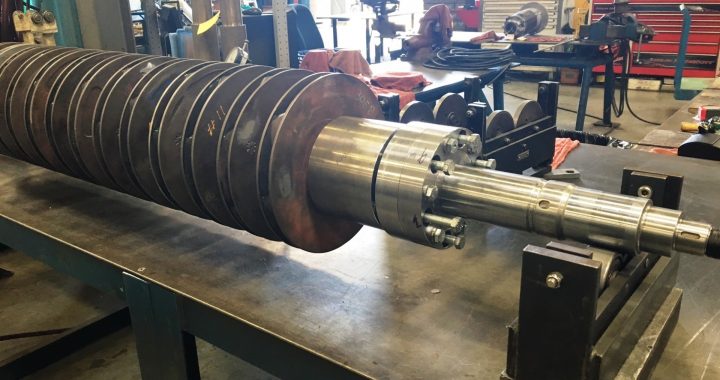

A major power plant in the United States experienced high vibration and recirculation issues with several ring section (BB4) boiler feed pumps, resulting in multiple catastrophic failures and unplanned outages. This case study details one of the pumps that was shipped to an aftermarket pump service center for a full analysis, troubleshooting, repair plan, rebuild and performance testing.

In combined-cycle plants, the demand for robust, yet expensive, barrel pumps diminished as the industry moved toward less expensive segmental rings pumps. Due to the recent shifts in the power industry, operators often face a shorter mean time between repair (MTBR), internal wear and high vibration issues on newly installed units.

After experiencing numerous boiler feed pump performance and reliability issues at their power plant, the plant owner opted to pursue a comprehensive root cause analysis and repair plan with an aftermarket pump service center in Los Angeles, California. The investigation ultimately revealed a series of underlying issues linked to the performance problems and unexpected pump failures.

Video: https://vimeo.com/452266877

Source: https://www.pumpsandsystems.com/analysis-engineering-upgrades-solve-ring-section-pump-failure