Operating a pump off its design point has many drawbacks. Inefficiency and wasting energy across a throttled valve bothrequire more horsepower than an optimized system. Running away from the best efficiency point increases risk of degradation, which may cause recurring premature component failures due to higher radial loads, hydraulic instability, and other influences. These factors negatively affect reliability while simultaneously driving up the cost of equipment operation and maintenance. For this reason, opportunities to optimize a pump are extremely beneficial and have a very short payback period.

Operating a pump off its design point has many drawbacks. Inefficiency and wasting energy across a throttled valve bothrequire more horsepower than an optimized system. Running away from the best efficiency point increases risk of degradation, which may cause recurring premature component failures due to higher radial loads, hydraulic instability, and other influences. These factors negatively affect reliability while simultaneously driving up the cost of equipment operation and maintenance. For this reason, opportunities to optimize a pump are extremely beneficial and have a very short payback period.

The benefits of modifying pump performance to better match system demand were demonstrated in a recent project undertaken at a Gulf Coast refinery. The refinery had a single-stage, double suction (BB2) pump where the required output had been greatly reduced from the original design. The mechanical seals were repeatedly failing, which resulted in frequent maintenance and seal replacements. The refinery partnered with Hydro, Inc to perform a field evaluation of the pump and develop a design upgrade to increase reliability and efficiency.

The benefits of modifying pump performance to better match system demand were demonstrated in a recent project undertaken at a Gulf Coast refinery. The refinery had a single-stage, double suction (BB2) pump where the required output had been greatly reduced from the original design. The mechanical seals were repeatedly failing, which resulted in frequent maintenance and seal replacements. The refinery partnered with Hydro, Inc to perform a field evaluation of the pump and develop a design upgrade to increase reliability and efficiency.

Read the full case study in World Pumps’ January/February digital edition to learn what steps were taken to effectively reduce flow for this “bad actor”, returning the asset to reliable operation and significantly reducing the cost to operate the equipment.

Do you have an initiative to save energy and reduce the lifecycle costs of your equipment? Hydro’s Energy Edge is a comprehensive program where we work hand-in-hand with end users to understand opportunities for asset optimization and develop plans to execute on chosen solutions.

Using experienced technical field advisors (TFAs) when performing field work is even more critical as equipment ages. During a typical lifetime, equipment will undergo multiple refurbishments that may change the dimensions of the internal element, casing, and discharge head. For BB5 pumps, commonly referred to within the industry as barrel pumps, the barrel usually remains installed in the system and is not sent out with the internal element and head for refurbishment. As the installation settles, foundation degrades, and components undergo repeated thermal expansion and contraction, this barrel can lose some of its dimensional integrity.

Using experienced technical field advisors (TFAs) when performing field work is even more critical as equipment ages. During a typical lifetime, equipment will undergo multiple refurbishments that may change the dimensions of the internal element, casing, and discharge head. For BB5 pumps, commonly referred to within the industry as barrel pumps, the barrel usually remains installed in the system and is not sent out with the internal element and head for refurbishment. As the installation settles, foundation degrades, and components undergo repeated thermal expansion and contraction, this barrel can lose some of its dimensional integrity. One of the greatest pitfalls in performing a successful field installation is blindly trusting the installation and operation manual (IOM) supplied with the equipment. While this document provides useful guidance, any component changes that have occurred, both intentional and unintentional, are not reflected here. It is also important not to presume that pumps running in parallel have identical barrels or that internal elements are interchangeable. Instead of falling victim to these assumptions, best practices include completing a field dimensional analysis.

One of the greatest pitfalls in performing a successful field installation is blindly trusting the installation and operation manual (IOM) supplied with the equipment. While this document provides useful guidance, any component changes that have occurred, both intentional and unintentional, are not reflected here. It is also important not to presume that pumps running in parallel have identical barrels or that internal elements are interchangeable. Instead of falling victim to these assumptions, best practices include completing a field dimensional analysis.

From its first storefront on Diversey Street in Chicago in 1969, Hydro has grown into an expansive service network that supports rotating equipment users worldwide. Our extensive footprint ensures that we can deliver our hallmark quality and exceptional customer service to clients across the globe.

From its first storefront on Diversey Street in Chicago in 1969, Hydro has grown into an expansive service network that supports rotating equipment users worldwide. Our extensive footprint ensures that we can deliver our hallmark quality and exceptional customer service to clients across the globe. By leveraging a diversity of expertise and resources, we can cater to the unique needs of each customer, ensuring timely and effective solutions that uphold our high standards of excellence. Some examples of niche capabilities within our network that can be leveraged by Hydro’s customers include:

By leveraging a diversity of expertise and resources, we can cater to the unique needs of each customer, ensuring timely and effective solutions that uphold our high standards of excellence. Some examples of niche capabilities within our network that can be leveraged by Hydro’s customers include:

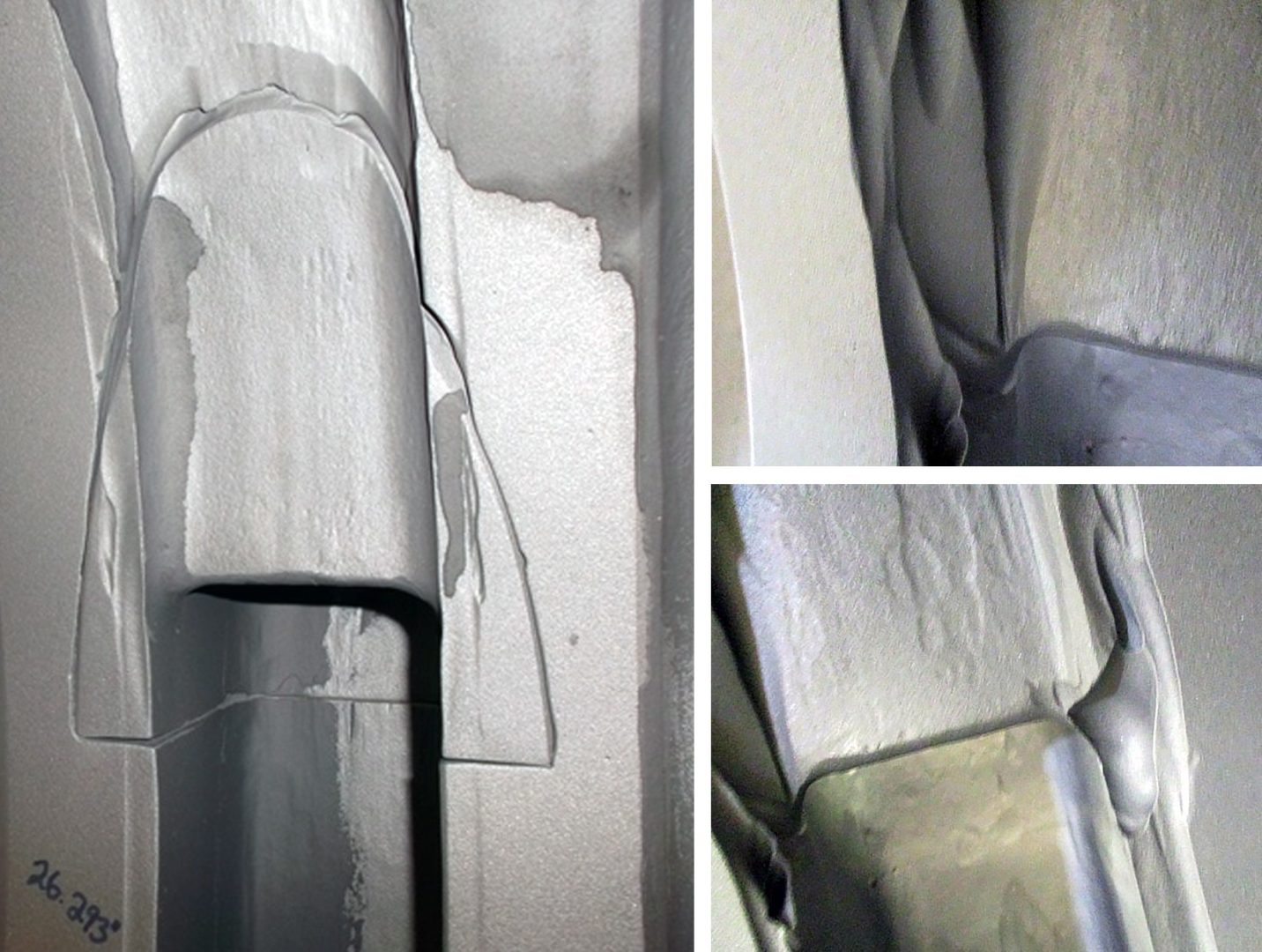

One of the key milestones in HydroTex Dynamics’ development was the time spent with Dr. Elemer Makay in the late 1980s and early 1990s perfecting the radial gap modifications (commonly known as A Gap, B Gap, and C Gap) on multistage diffuser-style pumps. Dr. Makay was a pioneer in battling impact loading and discharge recirculation in multistage pumps, failure modes that had historically caused high vibration, premature wear, and shaft failures for this equipment. He partnered with Jim Shaffer, founding partner of HydroTex Dynamics, in applying modifications that would combat these failure modes to drastically improve mean-time-between-repairs.

One of the key milestones in HydroTex Dynamics’ development was the time spent with Dr. Elemer Makay in the late 1980s and early 1990s perfecting the radial gap modifications (commonly known as A Gap, B Gap, and C Gap) on multistage diffuser-style pumps. Dr. Makay was a pioneer in battling impact loading and discharge recirculation in multistage pumps, failure modes that had historically caused high vibration, premature wear, and shaft failures for this equipment. He partnered with Jim Shaffer, founding partner of HydroTex Dynamics, in applying modifications that would combat these failure modes to drastically improve mean-time-between-repairs. Under the leadership of HydroTex Dynamics’ VP, Pete Erickson, they have continued to build upon this foundation by investing in advanced tooling, developing experienced shop talent, establishing a responsive field service unit, and fostering deep customer relationships grounded in trust and transparency. In 1995, they purchased the Pacific BFI line of BB5 pumps for North America, adding to their experience base in high energy, multistage pumps. They have on-site capability to perform 5-axis machining and can supply milled vane impellers with an industry leading turnaround time. While not currently certified, they are ISO compliant and follow all ISO practices.

Under the leadership of HydroTex Dynamics’ VP, Pete Erickson, they have continued to build upon this foundation by investing in advanced tooling, developing experienced shop talent, establishing a responsive field service unit, and fostering deep customer relationships grounded in trust and transparency. In 1995, they purchased the Pacific BFI line of BB5 pumps for North America, adding to their experience base in high energy, multistage pumps. They have on-site capability to perform 5-axis machining and can supply milled vane impellers with an industry leading turnaround time. While not currently certified, they are ISO compliant and follow all ISO practices.

Many of our aging facilities are still using the pumps that were purchased and commissioned during plant construction. Despite the age of this equipment, effective maintenance strategies and upgrade opportunities can extend useful life for decades more. Older pumps are often more robust than current designs, which take advantage of new manufacturing technologies to reduce the raw materials needed for construction. However, vintage equipment has its downfalls as well. It is important to understand the challenges we face when operating and maintaining vintage equipment so that we can stay ahead of potential sources for decreased reliability.

Many of our aging facilities are still using the pumps that were purchased and commissioned during plant construction. Despite the age of this equipment, effective maintenance strategies and upgrade opportunities can extend useful life for decades more. Older pumps are often more robust than current designs, which take advantage of new manufacturing technologies to reduce the raw materials needed for construction. However, vintage equipment has its downfalls as well. It is important to understand the challenges we face when operating and maintaining vintage equipment so that we can stay ahead of potential sources for decreased reliability.