Join instructor Mike Mancini as he explores how to determine where your equipment is running relative to the best efficiency point and how to use this information to optimize operation. This will include a discussion of pump curves, system curves, and detecting performance degradation using field data. Strategies for achieving peak efficiency and the benefits of these actions will also be discussed.

Tag Archives: energy savings

Empowering Pumps Maintenance & Reliability Summit

Join Hydro’s Bob Jennings for Empowering Pumps‘ Maintenance and Reliability Summit. Bob will be speaking at 11am CDT on Winning the Trifecta of Efficiency, Reliability, & Sustainability.

This presentation focuses on the technological advancements that have been made in recent years regarding data capturing, impeller redesign, impeller casting, CNC manufacturing (i.e., 5-axis milling), and acceptance testing.

It showcases the fact that technology is advancing so rapidly that processes that we used 5-10 years ago have become obsolete. Remedies which were cost prohibitive 10 years ago can now be readily and economically achieved. The pump repair industry has moved from product-based processes remedies to solution-based processes.

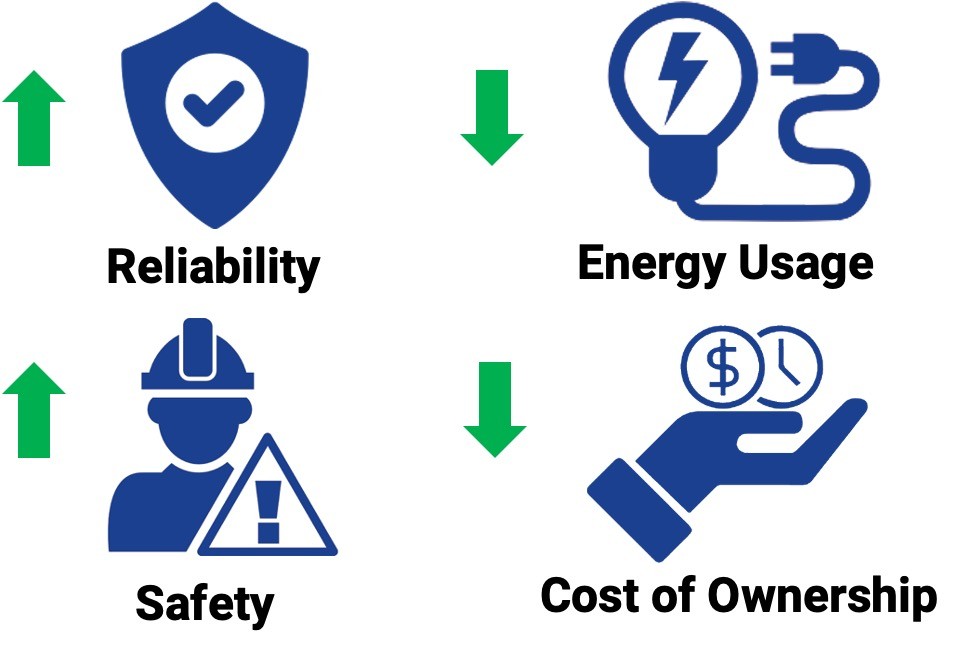

Combined, these result in meaningful energy reduction, improved equipment reliability and sustainability, while assisting the end user improve ESG scores through quantifiable reporting.

System Optimization

Boost Energy Efficiency and Accelerate Savings

It’s estimated that 85% of pumps are not optimized to their systems, costing end users both efficiency and reliability. To achieve operational excellence and reduce environmental impact, assessing and improving our systems is essential.

There is a lot of focus on buying new equipment with a higher energy efficiency rating. In reality, the efficiency gains available in optimizing efficiency within the pump design is usually dwarfed by the energy savings available by optimizing the way the pump operates within its system. Not only does optimizing a pump to its system result in a reduction in energy usage, it allows the pump to operate at its best efficiency point (BEP), where reliability is the greatest.

With today’s technology, optimizing a pumping system is achievable with less cost and a greater return on investment. Advancements in testing capabilities and analytical modeling help us to better understand and predict how fluid moves through a system, allowing us to identify more opportunities for improvement. These technologies also eliminate the uncertainty of planned modifications by assessing their effectiveness in a virtual environment.

When optimizing a pump to its system, it’s important to have a holistic mindset- looking beyond the pump boundaries, considering both mechanical and hydraulic performance, and understanding that system operation is affected as much by the people who operate it as it is the physical system itself. What tools are useful to have in your toolbox when approaching a system optimization project?

Energy Savings Audits- Understanding your Savings Potential

Many pump users focus on efficiency ratings when purchasing new equipment, but a much greater source of wasted energy is found when looking at the overall system instead of limiting optimization to the pump design itself. It is rare that a system is operating with equipment that is optimized to deliver flow while operating close to its best efficiency point. More often, pumps are oversized for their systems and achieve the desired flow rate by throttling a valve. The friction added by this valve changes the system curve to achieve the design operating flow; this action is one of the greatest sources of wasted energy in a pump system. Continue reading

Wednesday Webinar- Pump Curves and Energy Optimization

Join instructor Bob Jennings discusses pump curves and how to optimize pumps to their system to achieve energy savings.