Join Hydro’s Bob Jennings for Empowering Pumps‘ Maintenance and Reliability Summit. Bob will be speaking at 11am CDT on Winning the Trifecta of Efficiency, Reliability, & Sustainability.

This presentation focuses on the technological advancements that have been made in recent years regarding data capturing, impeller redesign, impeller casting, CNC manufacturing (i.e., 5-axis milling), and acceptance testing.

It showcases the fact that technology is advancing so rapidly that processes that we used 5-10 years ago have become obsolete. Remedies which were cost prohibitive 10 years ago can now be readily and economically achieved. The pump repair industry has moved from product-based processes remedies to solution-based processes.

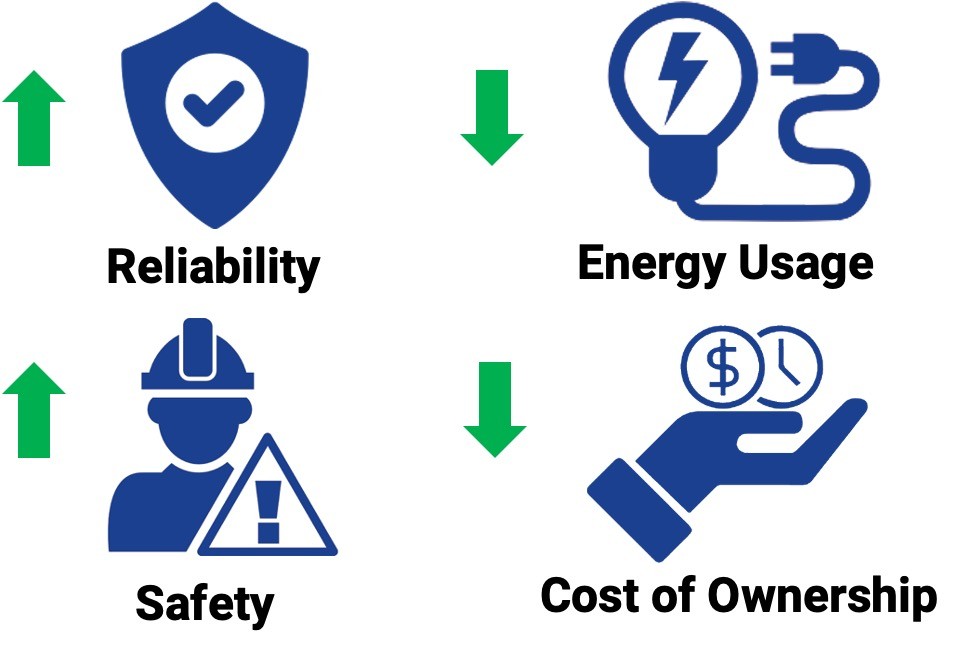

Combined, these result in meaningful energy reduction, improved equipment reliability and sustainability, while assisting the end user improve ESG scores through quantifiable reporting.