Why look backwards when you can be looking forward?

The problems you inherited with your pump and system design shouldn’t be an anchor holding you back from stable operation. Hydro’s mission to increase pump reliability extends beyond our service facilities and into the field. Hydro Reliability Services provides expert troubleshooting, advanced engineering analysis, and field mechanical and hydraulic testing for your rotating equipment.

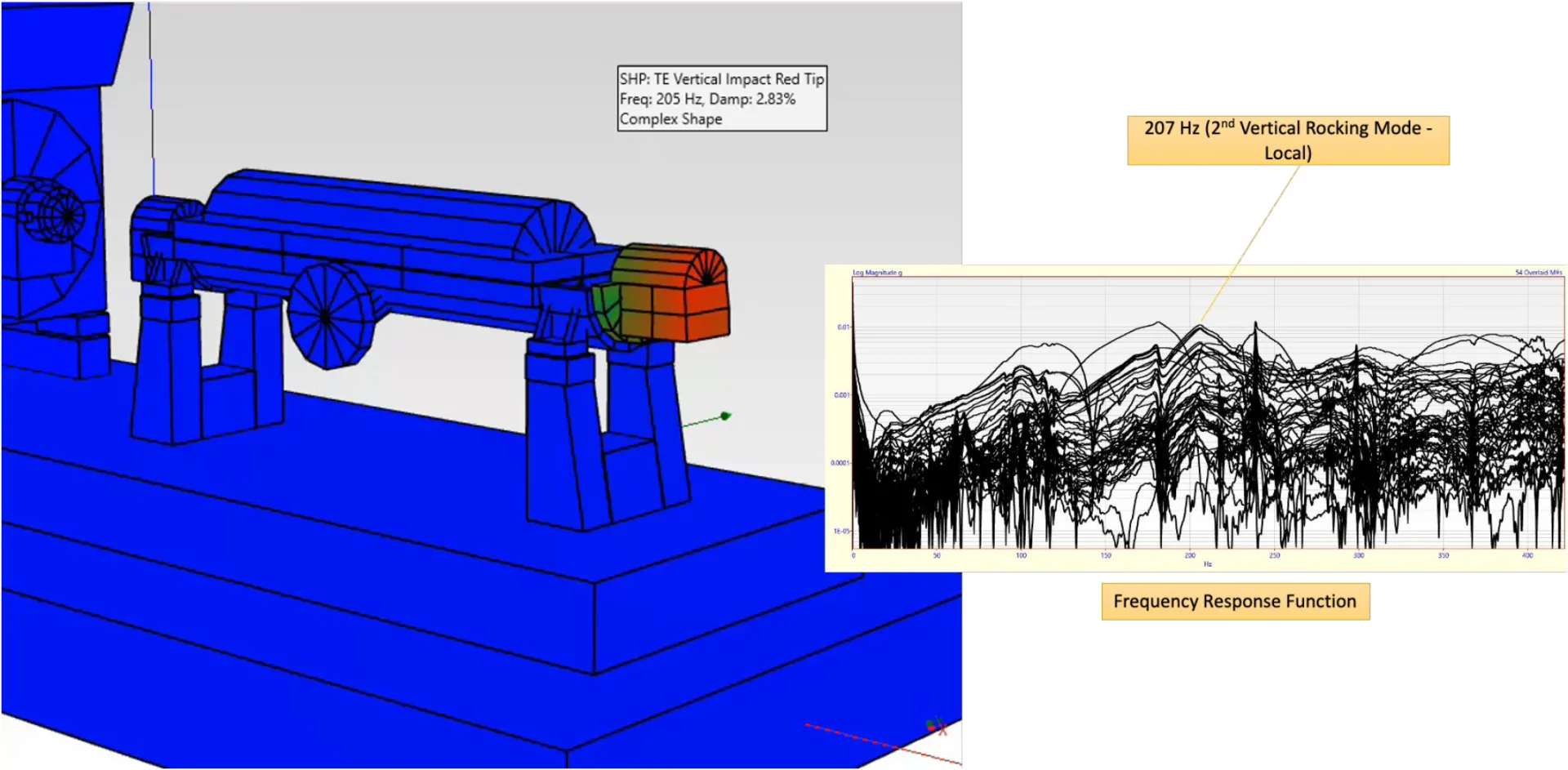

Many pump applications experience ongoing vibration and reliability issues; aging installations are also seeing margins between operation and resonant conditions eroding and previously reliable equipment being pulled into problems. The root cause of these problems is often resonance, a condition that is often misdiagnosed and commonly goes undiagnosed, resulting in persistent high amplitude vibration issues for long periods of time. Structural resonance typically results in highly directional vibration and increased amplitudes that can be difficult to resolve without the proper engineering approach. Fortunately, technology has developed to diagnose resonance and develop effective solutions without resorting to costly trial-and-error methods.

Many pump applications experience ongoing vibration and reliability issues; aging installations are also seeing margins between operation and resonant conditions eroding and previously reliable equipment being pulled into problems. The root cause of these problems is often resonance, a condition that is often misdiagnosed and commonly goes undiagnosed, resulting in persistent high amplitude vibration issues for long periods of time. Structural resonance typically results in highly directional vibration and increased amplitudes that can be difficult to resolve without the proper engineering approach. Fortunately, technology has developed to diagnose resonance and develop effective solutions without resorting to costly trial-and-error methods.

To help our customers solve complex problems with critical pumping equipment, Hydro Reliability Services’ engineers bring an array of technology to the site. Monitoring of traditional health indicators – flow, power, vibration, and pressure – is supplemented with advanced technology, such as Operating Deflection Shape and Experimental Modal Analysis. Leveraging their expertise and advanced modeling software, Hydro’s reliability engineers analyze this data to determine design and system weaknesses and propose improvements. This assessment gives you the ammunition you need to make an informed judgment about the risk of current and future operation.

Read our recent case study in Pumps & Systems magazine to learn more about how field testing and troubleshooting helped a power plant resolve a vibration issue in a critical application.

What does more effective troubleshooting mean for you?

- Maintaining a competitive edge in your marketplace through reduced operation and maintenance costs

- Creating a safer workplace with much lower risk of equipment-related accidents and reduced exposure to hazardous materials

- Contribution towards a sustainable future through more efficient operation and reduced risk of product leakage into the environment

- Ability to focus resources on proactive strategies and process innovation instead of continuously reacting to problem equipment

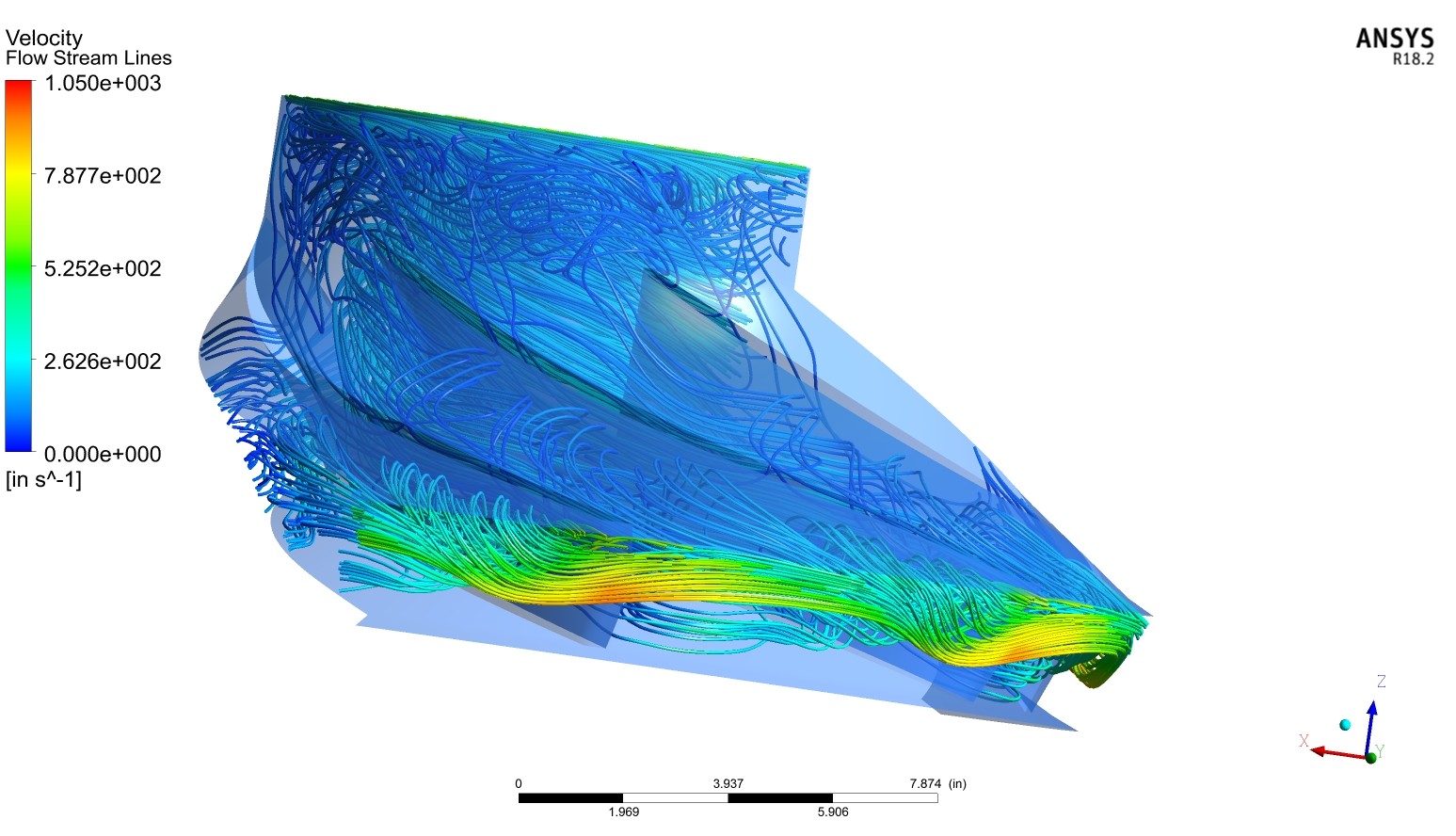

Many OEMs focus on the initial pump design and providing a higher peak efficiency. While this can provide energy savings, it misses some of the greatest gains available. With our history in developing solutions for the aftermarket, Hydro approaches energy efficiency differently. Our unique experience as a brand-agnostic company focused on end users’ existing installed equipment has provided us with insight into improving equipment performance by understanding how it operates as a part of the greater system. This has allowed us to provide significant energy savings for our partners, as shown in successful cases such as

Many OEMs focus on the initial pump design and providing a higher peak efficiency. While this can provide energy savings, it misses some of the greatest gains available. With our history in developing solutions for the aftermarket, Hydro approaches energy efficiency differently. Our unique experience as a brand-agnostic company focused on end users’ existing installed equipment has provided us with insight into improving equipment performance by understanding how it operates as a part of the greater system. This has allowed us to provide significant energy savings for our partners, as shown in successful cases such as  Hydro’s Energy Edge program takes advantage of our in-house engineering, field testing, remanufacturing, and parts capabilities to provide an end-to-end solution to improve energy usage and reliability. The process starts with getting the necessary design and operation data to perform a comprehensive analysis of current performance and identify opportunities for improvement. Depending on the findings, solutions can range from system operations recommendations to hydraulic modifications to a completely redesigned drop-in replacement. By providing a custom solution instead of an off-the-shelf replacement, Hydro not only optimizes performance, but minimizes cost, lead time, and risk by ensuring that the solutions fits into the existing equipment footprint.

Hydro’s Energy Edge program takes advantage of our in-house engineering, field testing, remanufacturing, and parts capabilities to provide an end-to-end solution to improve energy usage and reliability. The process starts with getting the necessary design and operation data to perform a comprehensive analysis of current performance and identify opportunities for improvement. Depending on the findings, solutions can range from system operations recommendations to hydraulic modifications to a completely redesigned drop-in replacement. By providing a custom solution instead of an off-the-shelf replacement, Hydro not only optimizes performance, but minimizes cost, lead time, and risk by ensuring that the solutions fits into the existing equipment footprint.

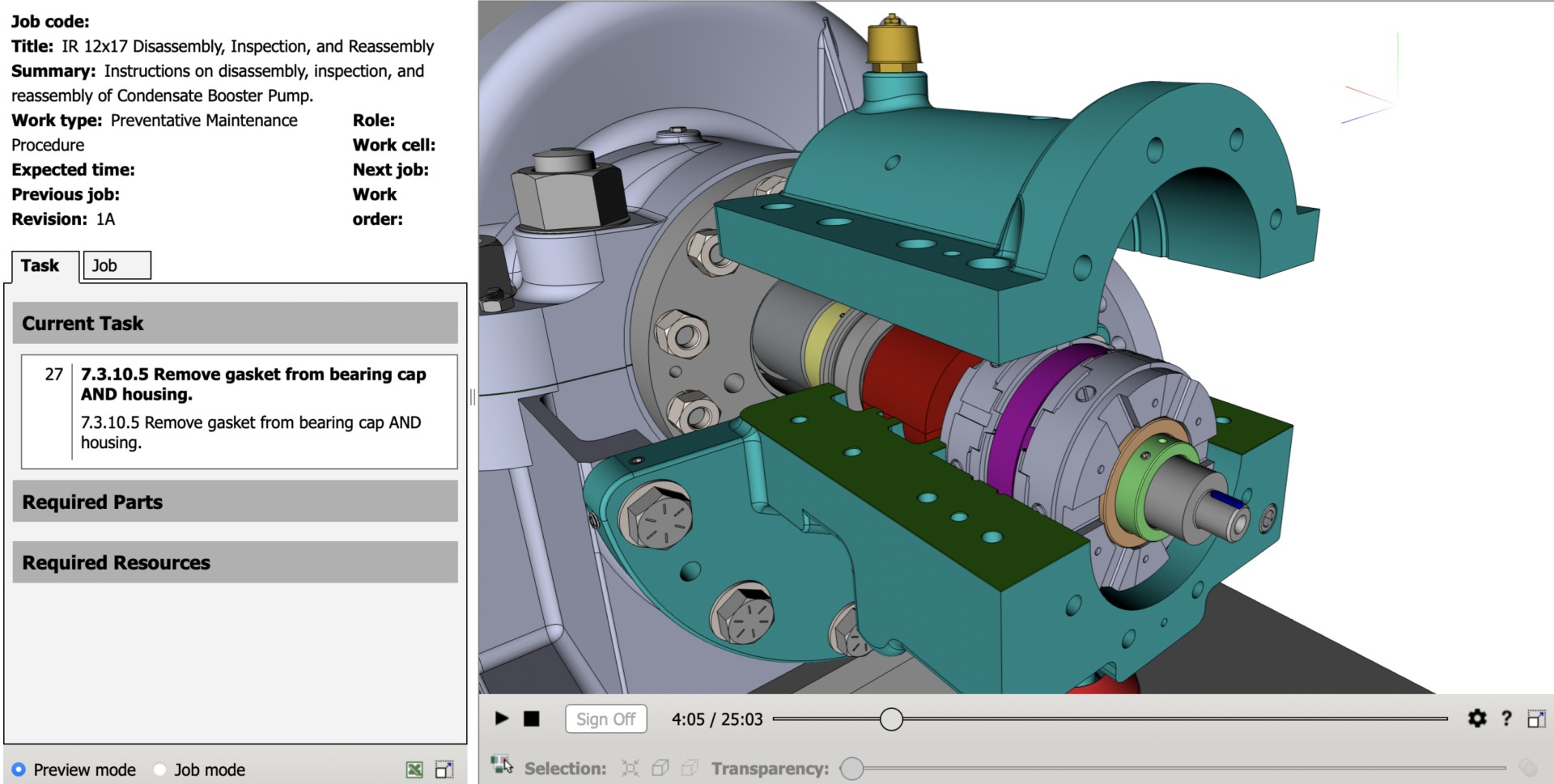

Hydro specifies machining and fit-up tolerances that often exceed the required industry standards and are best-in-class for the pump industry. Taking the extra time to meet more stringent tolerances ensures better concentricity and parallelism of critical components, reducing the risk of contact between the rotating and stationary elements during operation. Reducing component contact will result in reduced vibration and reduce the rate of wear for close clearance components. Maintaining design clearances greatly contributes to longer mean-time-between-repairs by providing greater stiffness and damping to the rotating assembly and reducing internal recirculation, which in turn affects performance and efficiency. To learn more about the importance of maintaining design clearances,

Hydro specifies machining and fit-up tolerances that often exceed the required industry standards and are best-in-class for the pump industry. Taking the extra time to meet more stringent tolerances ensures better concentricity and parallelism of critical components, reducing the risk of contact between the rotating and stationary elements during operation. Reducing component contact will result in reduced vibration and reduce the rate of wear for close clearance components. Maintaining design clearances greatly contributes to longer mean-time-between-repairs by providing greater stiffness and damping to the rotating assembly and reducing internal recirculation, which in turn affects performance and efficiency. To learn more about the importance of maintaining design clearances,

From lifting massive weights, to reverse engineering components with expansive surface areas, to troubleshooting vibration in machines susceptible to resonance problems, large vertical pumps have unique challenges. Fortunately, Hydro has cultivated specialized capabilities to meet these challenges.

From lifting massive weights, to reverse engineering components with expansive surface areas, to troubleshooting vibration in machines susceptible to resonance problems, large vertical pumps have unique challenges. Fortunately, Hydro has cultivated specialized capabilities to meet these challenges. Another challenge when working on large pumps is that they require a shop with the appropriate tooling and lifting capacity. It also requires a team dedicated to providing a higher standard of repair. Because vertical pumps are made of several stacked components, maintaining tight tolerances and best-in-class fit-ups is critical for reliable operation. Hydro’s standards are more stringent than those required by any industry body. This translates to longer life, better performance, and safer operation.

Another challenge when working on large pumps is that they require a shop with the appropriate tooling and lifting capacity. It also requires a team dedicated to providing a higher standard of repair. Because vertical pumps are made of several stacked components, maintaining tight tolerances and best-in-class fit-ups is critical for reliable operation. Hydro’s standards are more stringent than those required by any industry body. This translates to longer life, better performance, and safer operation.