Why Technical Expertise plays a Critical Role in Equipment Maintenance

As the industrial world becomes more competitive, reducing costs is key for maintaining an advantage in the marketplace. As such, many end users have become more cost-conscious when approaching equipment repair. In some services- where equipment is not complex and performance doesn’t affect process availability or quality- this strategy can provide some benefit. However, the short-term gain of a lower repair price often turns into long-term cost increases when a lack of engineering capability impacts equipment reliability and performance.

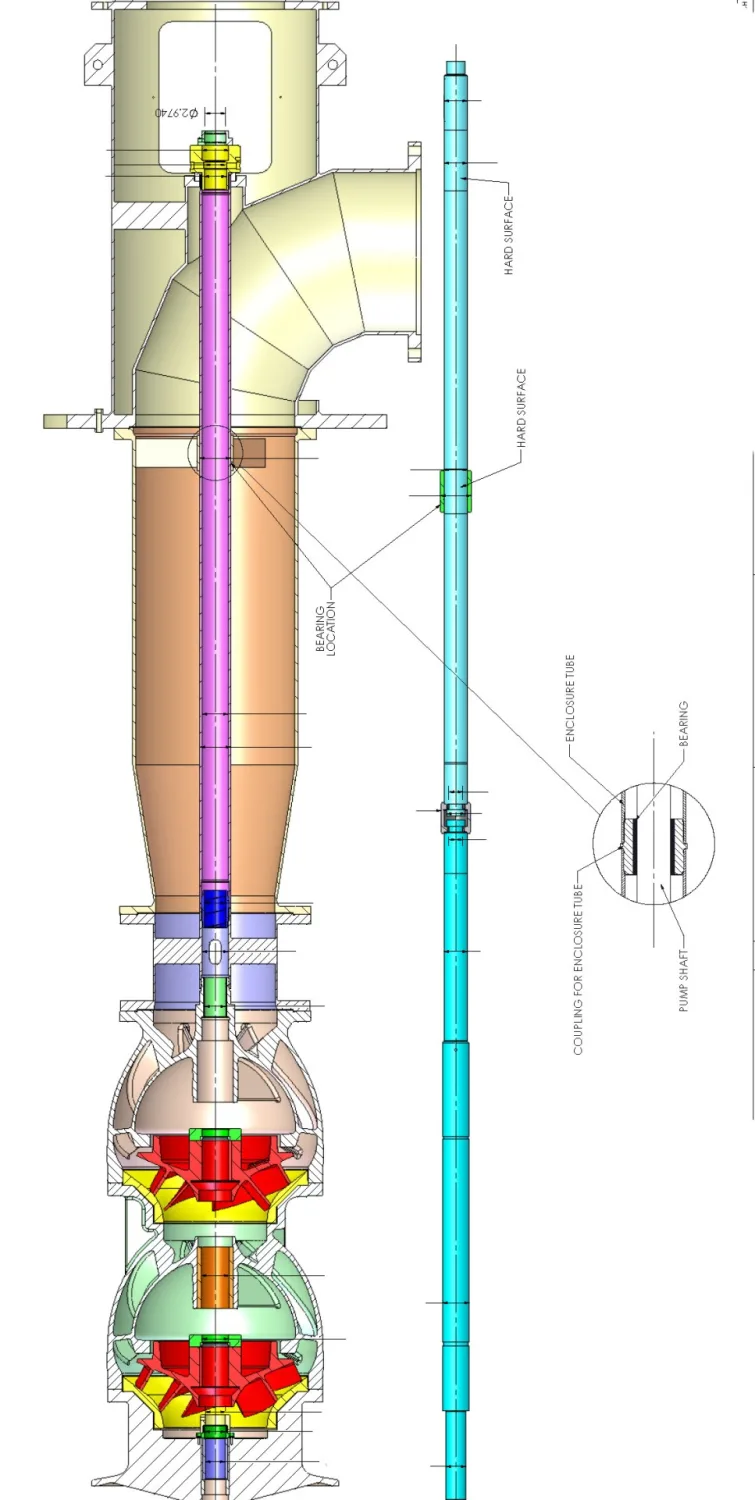

The importance of engaging with a facility that has strong engineering capabilities and subject matter expertise was proven during a series of boiler feed pump repairs for a Canadian biomass power plant. Like many biomass facilities, this plant had segmental ring boiler feed pumps, also commonly referred to as BB4 pumps. This is a complex design installed in a high energy, critical application, with numerous stacked and nested components that must be kept in alignment.

The importance of engaging with a facility that has strong engineering capabilities and subject matter expertise was proven during a series of boiler feed pump repairs for a Canadian biomass power plant. Like many biomass facilities, this plant had segmental ring boiler feed pumps, also commonly referred to as BB4 pumps. This is a complex design installed in a high energy, critical application, with numerous stacked and nested components that must be kept in alignment.

In this case, a small shop had completed several repairs that had resulted in high vibration and performance issues. These pumps were a legacy design that was no longer supported by the OEM and required engineering knowledge to properly refurbish and set the balance device. As such, it was important to find a repair partner that had a strong understanding of pump design. The plant worked with Hydro’s Scotford facility to bring these “bad actor” pumps back to optimal performance.

Read the full case study in World Pumps‘ March/April 2025 edition here.

Many of our aging facilities are still using the pumps that were purchased and commissioned during plant construction. Despite the age of this equipment, effective maintenance strategies and upgrade opportunities can extend useful life for decades more. Older pumps are often more robust than current designs, which take advantage of new manufacturing technologies to reduce the raw materials needed for construction. However, vintage equipment has its downfalls as well. It is important to understand the challenges we face when operating and maintaining vintage equipment so that we can stay ahead of potential sources for decreased reliability.

Many of our aging facilities are still using the pumps that were purchased and commissioned during plant construction. Despite the age of this equipment, effective maintenance strategies and upgrade opportunities can extend useful life for decades more. Older pumps are often more robust than current designs, which take advantage of new manufacturing technologies to reduce the raw materials needed for construction. However, vintage equipment has its downfalls as well. It is important to understand the challenges we face when operating and maintaining vintage equipment so that we can stay ahead of potential sources for decreased reliability.

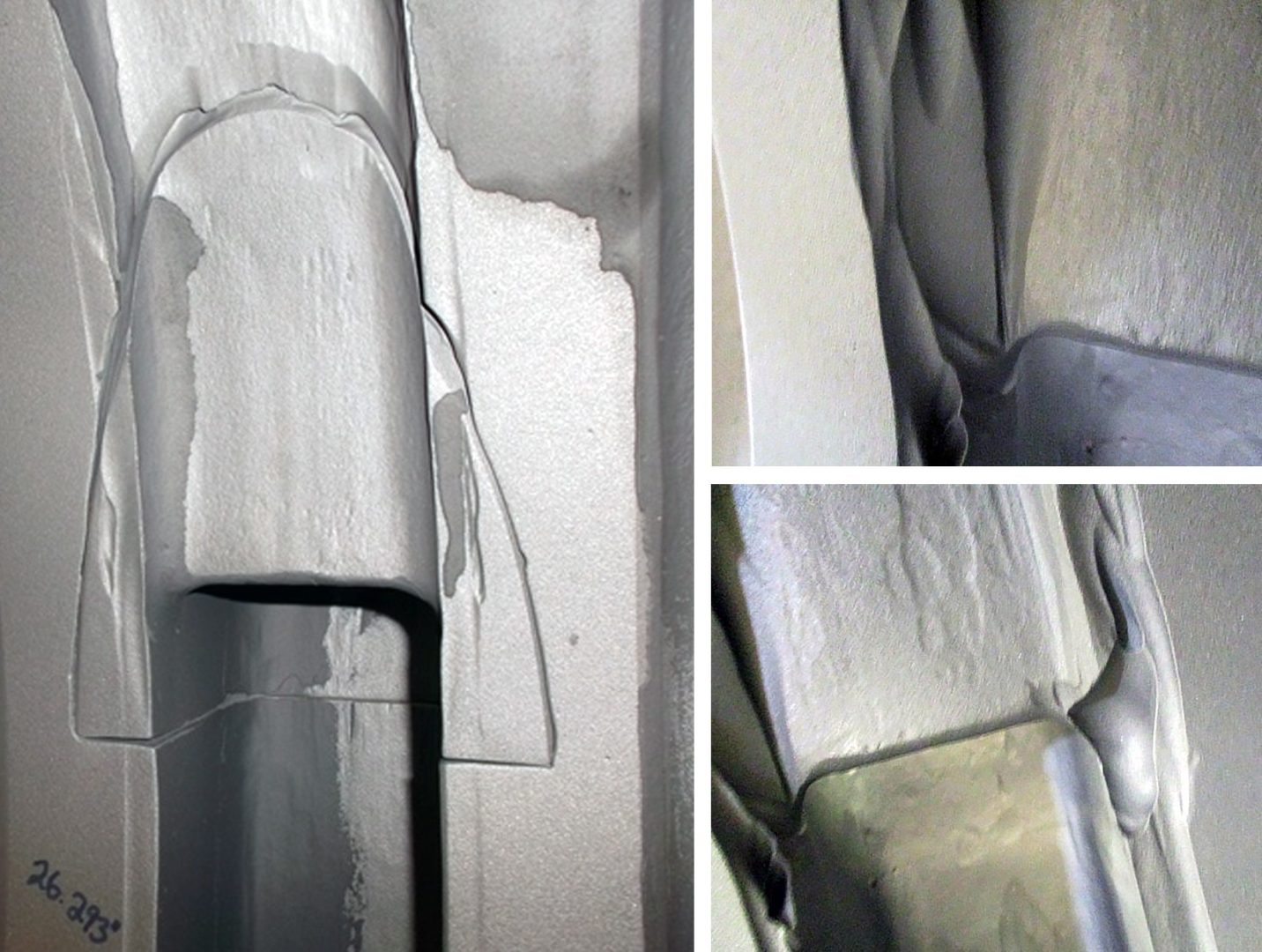

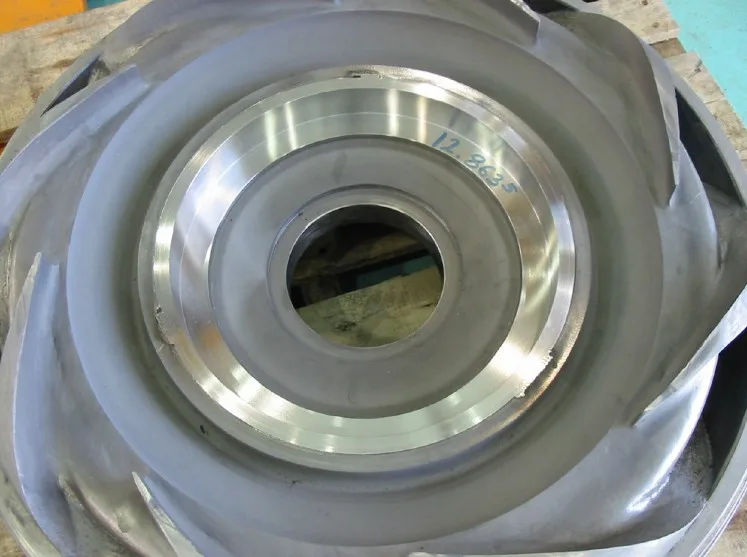

Hydro manufactured new wear rings without slots to prevent the abrasive material from damaging the case and minimize wear behind the casing wear rings. The worn areas of the casing and a new sleeve were overlaid with tungsten carbide to prevent further damage.

Hydro manufactured new wear rings without slots to prevent the abrasive material from damaging the case and minimize wear behind the casing wear rings. The worn areas of the casing and a new sleeve were overlaid with tungsten carbide to prevent further damage.

Industrial pumps are sometimes repaired or modified by smaller local repair shops that do not have the engineering oversight to ensure that the repairs and modifications meet the original design’s intent. When Hydro received this pump, it was clear that prior modifications that had been performed without engineering review were causing problems.

Industrial pumps are sometimes repaired or modified by smaller local repair shops that do not have the engineering oversight to ensure that the repairs and modifications meet the original design’s intent. When Hydro received this pump, it was clear that prior modifications that had been performed without engineering review were causing problems.