Hydro is proud to be presenting again at the 2025 Turbo Pump Symposia in Houston, TX! Join presenters Dr. Gary Dyson and Freddy Cardenas Linero as they discuss a case study where advanced engineering was used to dramatically increase flow of a shipping pump in an oil and gas terminal facility.

Wednesday, September 17, 2025 | 2:00 – 2:45pm | Room 370A

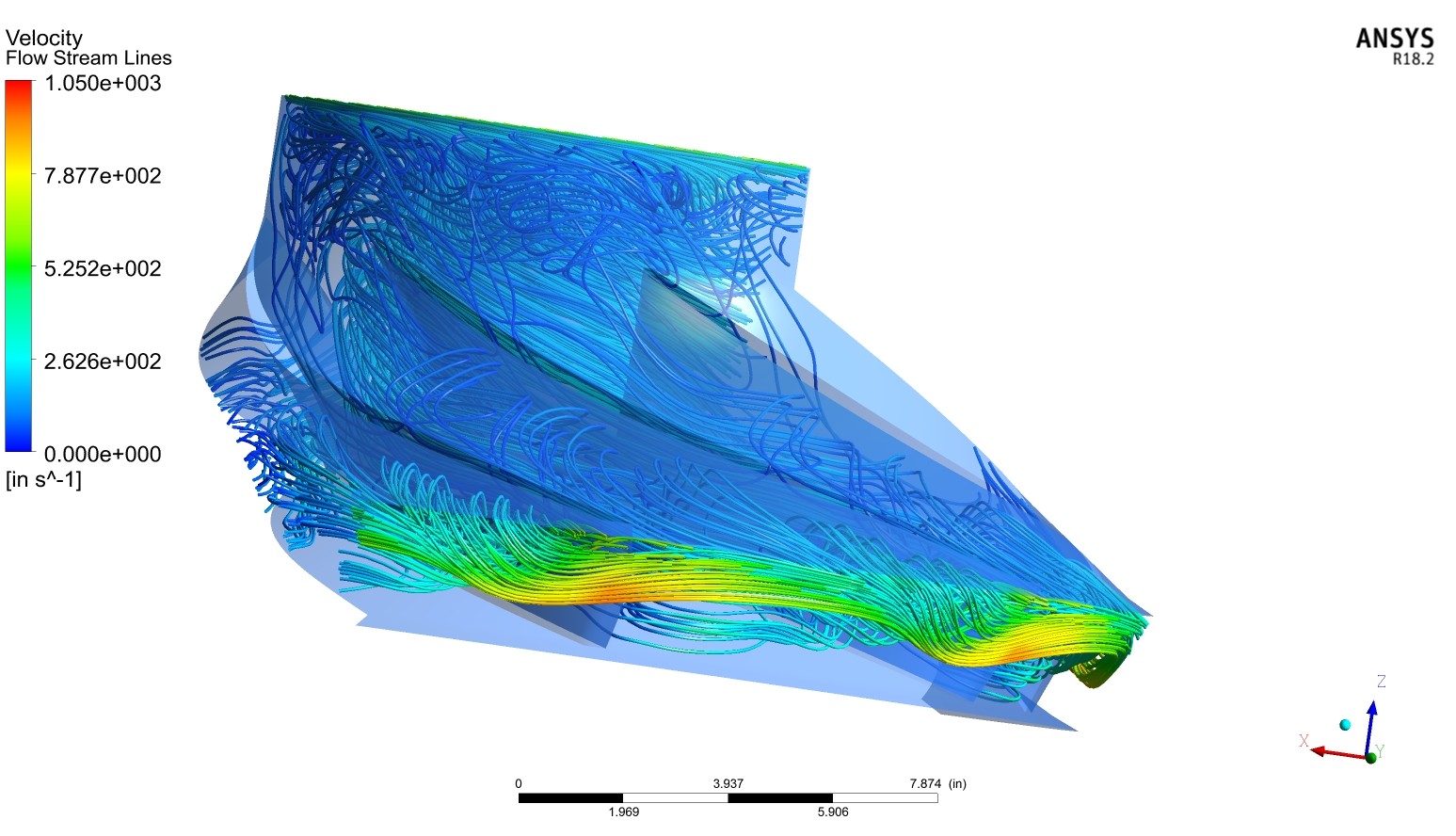

Centrifugal pumps are critical to fluid handling systems, but as operational demands evolve, optimizing performance becomes essential. This lecture will present a successful hydraulic re-rate of a propane shipping pump (P-1010) at Phoenix Park Gas Processors’ Hull facility in Texas, aiming to double railcar loading capacity without major system modifications. Instead of replacing the pump, a process requiring over 40 weeks of lead time and costly infrastructure changes, the project used a duplicate unit sourced from the aftermarket. It was reverse engineered, hydraulically redesigned, and optimized using CFD simulations to shift the Best Efficiency Point from 350 GPM to 800 GPM while reducing head by 60%.

The study highlights the importance of combining CFD analysis with mechanical evaluation to ensure reliable performance. It outlines a structured methodology from feasibility assessment to installation, including modeling, manufacturing, quality control, and commissioning. This project demonstrates how a targeted hydraulic re-rate can extend equipment life, increase throughput, and reduce energy use and capital costs, all while maintaining existing mechanical and system constraints.

Find out more about this year’s Turbo Pump Symposia here.

Learn more about Hydro’s Engineering Services.

Operating a pump off its design point has many drawbacks. Inefficiency and wasting energy across a throttled valve bothrequire more horsepower than an optimized system. Running away from the best efficiency point increases risk of degradation, which may cause recurring premature component failures due to higher radial loads, hydraulic instability, and other influences. These factors negatively affect reliability while simultaneously driving up the cost of equipment operation and maintenance. For this reason, opportunities to optimize a pump are extremely beneficial and have a very short payback period.

Operating a pump off its design point has many drawbacks. Inefficiency and wasting energy across a throttled valve bothrequire more horsepower than an optimized system. Running away from the best efficiency point increases risk of degradation, which may cause recurring premature component failures due to higher radial loads, hydraulic instability, and other influences. These factors negatively affect reliability while simultaneously driving up the cost of equipment operation and maintenance. For this reason, opportunities to optimize a pump are extremely beneficial and have a very short payback period. The benefits of modifying pump performance to better match system demand were demonstrated in a recent project undertaken at a Gulf Coast refinery. The refinery had a single-stage, double suction (BB2) pump where the required output had been greatly reduced from the original design. The mechanical seals were repeatedly failing, which resulted in frequent maintenance and seal replacements. The refinery partnered with Hydro, Inc to perform a field evaluation of the pump and develop a design upgrade to increase reliability and efficiency.

The benefits of modifying pump performance to better match system demand were demonstrated in a recent project undertaken at a Gulf Coast refinery. The refinery had a single-stage, double suction (BB2) pump where the required output had been greatly reduced from the original design. The mechanical seals were repeatedly failing, which resulted in frequent maintenance and seal replacements. The refinery partnered with Hydro, Inc to perform a field evaluation of the pump and develop a design upgrade to increase reliability and efficiency.

Many OEMs focus on the initial pump design and providing a higher peak efficiency. While this can provide energy savings, it misses some of the greatest gains available. With our history in developing solutions for the aftermarket, Hydro approaches energy efficiency differently. Our unique experience as a brand-agnostic company focused on end users’ existing installed equipment has provided us with insight into improving equipment performance by understanding how it operates as a part of the greater system. This has allowed us to provide significant energy savings for our partners, as shown in successful cases such as

Many OEMs focus on the initial pump design and providing a higher peak efficiency. While this can provide energy savings, it misses some of the greatest gains available. With our history in developing solutions for the aftermarket, Hydro approaches energy efficiency differently. Our unique experience as a brand-agnostic company focused on end users’ existing installed equipment has provided us with insight into improving equipment performance by understanding how it operates as a part of the greater system. This has allowed us to provide significant energy savings for our partners, as shown in successful cases such as  Hydro’s Energy Edge program takes advantage of our in-house engineering, field testing, remanufacturing, and parts capabilities to provide an end-to-end solution to improve energy usage and reliability. The process starts with getting the necessary design and operation data to perform a comprehensive analysis of current performance and identify opportunities for improvement. Depending on the findings, solutions can range from system operations recommendations to hydraulic modifications to a completely redesigned drop-in replacement. By providing a custom solution instead of an off-the-shelf replacement, Hydro not only optimizes performance, but minimizes cost, lead time, and risk by ensuring that the solutions fits into the existing equipment footprint.

Hydro’s Energy Edge program takes advantage of our in-house engineering, field testing, remanufacturing, and parts capabilities to provide an end-to-end solution to improve energy usage and reliability. The process starts with getting the necessary design and operation data to perform a comprehensive analysis of current performance and identify opportunities for improvement. Depending on the findings, solutions can range from system operations recommendations to hydraulic modifications to a completely redesigned drop-in replacement. By providing a custom solution instead of an off-the-shelf replacement, Hydro not only optimizes performance, but minimizes cost, lead time, and risk by ensuring that the solutions fits into the existing equipment footprint.