Vertical pumps are especially susceptible to minor conditions that can result in elevated vibration amplitudes. The vertically suspended design and long stationary element lengths often combine into natural frequencies that are near forcing frequencies, such as running speed or even sub-synchronous faults. The complexity of these issues makes it difficult to diagnose and resolve persistent vibration issues with the type of data that is routinely available to the end users.

In-depth field testing paired with computational analysis provides a clear path to both an accurate diagnosis and a solution that has a high likelihood of success. The effectiveness of this methodology was proven for a Gulf Coast midstream company who was experiencing high vibration with their vertical freshwater pumps. By applying advanced field diagnostics, the end user was able to understand the underlying causes of the vibration and evaluate possible solutions in a theoretical environment prior to implementing them in the field.

In-depth field testing paired with computational analysis provides a clear path to both an accurate diagnosis and a solution that has a high likelihood of success. The effectiveness of this methodology was proven for a Gulf Coast midstream company who was experiencing high vibration with their vertical freshwater pumps. By applying advanced field diagnostics, the end user was able to understand the underlying causes of the vibration and evaluate possible solutions in a theoretical environment prior to implementing them in the field.

Read the full case study, published in the May 2025 edition of Pumps & Systems magazine, here.

Read more case studies on vibration analysis and the work completed by Hydro Reliability Services here.

The importance of engaging with a facility that has strong engineering capabilities and subject matter expertise was proven during a series of boiler feed pump repairs for a Canadian biomass power plant. Like many biomass facilities, this plant had segmental ring boiler feed pumps, also commonly referred to as BB4 pumps. This is a complex design installed in a high energy, critical application, with numerous stacked and nested components that must be kept in alignment.

The importance of engaging with a facility that has strong engineering capabilities and subject matter expertise was proven during a series of boiler feed pump repairs for a Canadian biomass power plant. Like many biomass facilities, this plant had segmental ring boiler feed pumps, also commonly referred to as BB4 pumps. This is a complex design installed in a high energy, critical application, with numerous stacked and nested components that must be kept in alignment.

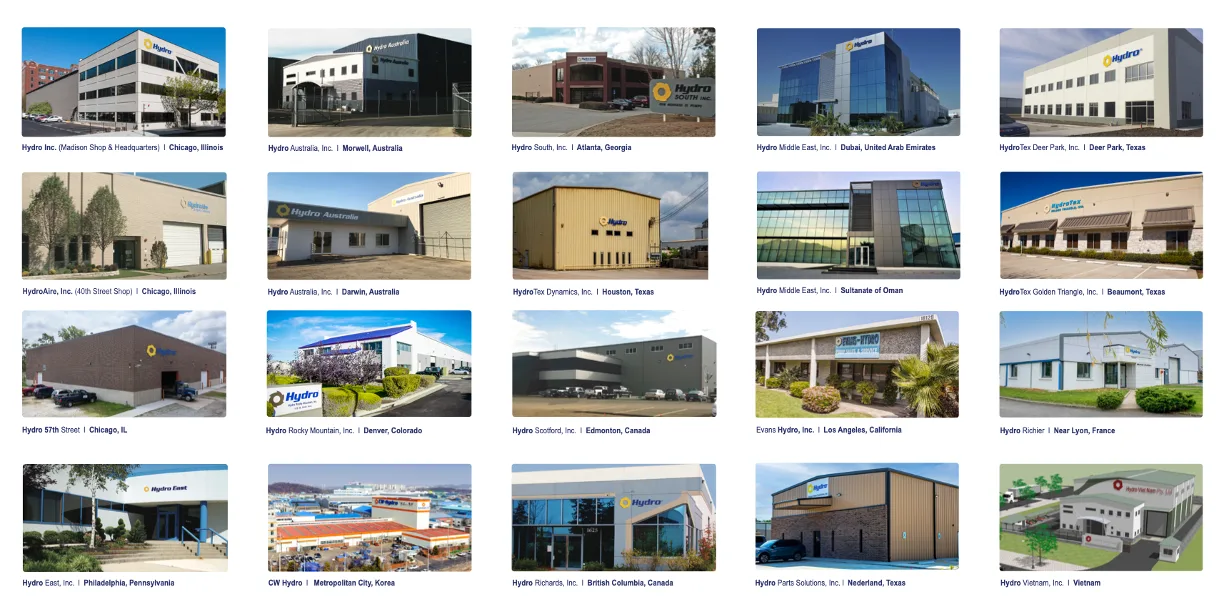

From its first storefront on Diversey Street in Chicago in 1969, Hydro has grown into an expansive service network that supports rotating equipment users worldwide. Our extensive footprint ensures that we can deliver our hallmark quality and exceptional customer service to clients across the globe.

From its first storefront on Diversey Street in Chicago in 1969, Hydro has grown into an expansive service network that supports rotating equipment users worldwide. Our extensive footprint ensures that we can deliver our hallmark quality and exceptional customer service to clients across the globe. By leveraging a diversity of expertise and resources, we can cater to the unique needs of each customer, ensuring timely and effective solutions that uphold our high standards of excellence. Some examples of niche capabilities within our network that can be leveraged by Hydro’s customers include:

By leveraging a diversity of expertise and resources, we can cater to the unique needs of each customer, ensuring timely and effective solutions that uphold our high standards of excellence. Some examples of niche capabilities within our network that can be leveraged by Hydro’s customers include:

Hydro specifies machining and fit-up tolerances that often exceed the required industry standards and are best-in-class for the pump industry. Taking the extra time to meet more stringent tolerances ensures better concentricity and parallelism of critical components, reducing the risk of contact between the rotating and stationary elements during operation. Reducing component contact will result in reduced vibration and reduce the rate of wear for close clearance components. Maintaining design clearances greatly contributes to longer mean-time-between-repairs by providing greater stiffness and damping to the rotating assembly and reducing internal recirculation, which in turn affects performance and efficiency. To learn more about the importance of maintaining design clearances,

Hydro specifies machining and fit-up tolerances that often exceed the required industry standards and are best-in-class for the pump industry. Taking the extra time to meet more stringent tolerances ensures better concentricity and parallelism of critical components, reducing the risk of contact between the rotating and stationary elements during operation. Reducing component contact will result in reduced vibration and reduce the rate of wear for close clearance components. Maintaining design clearances greatly contributes to longer mean-time-between-repairs by providing greater stiffness and damping to the rotating assembly and reducing internal recirculation, which in turn affects performance and efficiency. To learn more about the importance of maintaining design clearances,