Join us for our November webinar, where instructor Mike Mancini discusses Discharge Recirculation, its effects on pump performance, and best practices for improving efficiency and reliability.

Tag Archives: reliability

Wednesday Webinar: Rolling Element Bearings

Join us for October’s webinar, where instructor Glen Powell presents a course rooted in the extensive expertise and material developed by the late Heinz Bloch, a renowned authority in machinery reliability and engineering. Bloch’s work continues to shape best practices in bearing selection, optimization, and failure prevention. This session will highlight his invaluable insights and strategies, equipping participants to improve bearing performance and confidently justify upgrades.

Wednesday Webinar: Pump Hydraulics Broken Down!

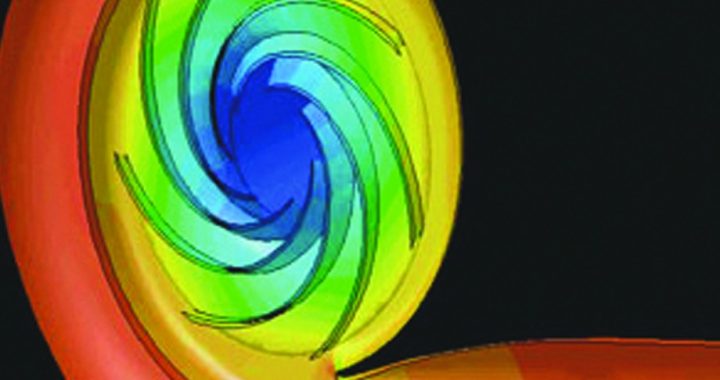

Join us for our June webinar, where Dr. Gary Dyson breaks down pump hydraulics and their effect on pump health and performance. Learn how fluid movement has consequences for pump reliability.

Wednesday Webinar: Primary Failure Mode of Single Stage Pumps

Join us for our May webinar, where instructor Mike Mancini presents an in-depth look at the failure modes of single stage pumps, including single stage double suction (BB1/BB2) pumps and overhung (OH1/OH2) pumps. Gain valuable knowledge to improve pump performance and operational reliability.

Seminar: Taming the Bad Actors- Chicago (In-Person)

Join us for our free one-day seminar on Taming the Bad Actors. Instructor Bob Jennings discusses how to identify root cause failures and improve the performance of your pumping systems.

This seminar is held in person at our HydroAire 40th Street facility in Chicago.