Written by: Ron White & Ben Roberson, HydroAire Inc.

A “temporary” repair results in five years of service.

Five years ago, an engineered pump service center in the Midwest received a call from a large municipal sanitary district. One of the company’s four submersible pumps had tripped the overloads. This 890-rpm unit operated on variable frequency drives that adjusted the motor speed to match the fluid inflow. Once it had been reset, the 290-horsepower, 42-inch diameter axial flow pump exhibited significant vibration before failing. The pump was removed and sent to the service center where it was cleaned, disassembled and inspected by a team of skilled professionals dedicated to repairing submersible pumps.

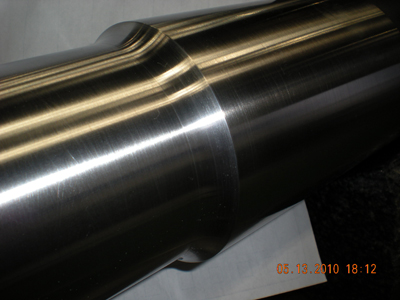

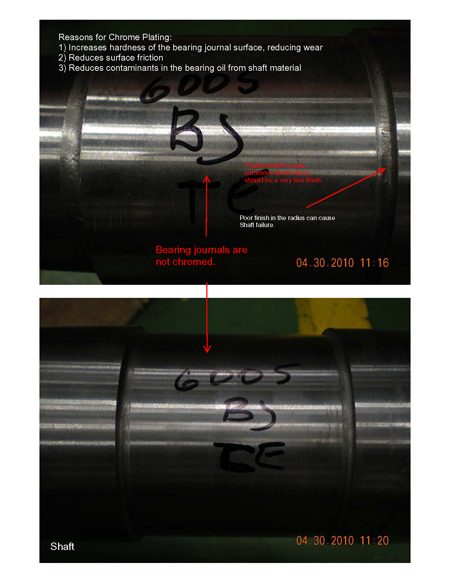

Figure 1. 290-horsepower submersible pump upon arrival at the service center

The Assessment

The initial inspection revealed that a large chunk of concrete debris from nearby sewer construction caused the submersible pump to fail. The inspection also showed that the pump had several problems:

- A section of the trailing edge of one of the impeller vanes was broken.

- The rotating ring was missing.

- The impeller hub and lower mechanical seal had cracked and caused damage to the shaft keyway.

Figure 2. The cracked impeller hub

When the municipality inquired about replacement parts from the OEM, delivery was estimated at a 12- to 14-week turnaround time on a new impeller from Europe. The municipality could not afford to be without the pump for an extended period of time. Having a great deal of experience with submersible pumps, the dedicated submersible repair division proposed a temporary solution to get the pump repaired and back into service until the municipality could obtain a new impeller from the OEM.