Hydro, Inc. introduces Centaur, its Wireless Condition Monitoring Solution. Centaur provides users with remote monitoring allowing for operators and engineers to observe equipment performance in real-time enabling predictive analytics, vibration monitoring, and temperature readings to optimize critical asset maintenance strategies.

Centaur offers advanced data analysis support, backed by Hydro’s diversified and unbiased pump knowledge base, which spans across a broad spectrum of manufacturers and designs. With highly customized dashboards and automated alarm notifications, Centaur can alert users before a critical asset experiences a failure or previously unforeseen event.

The benefits realized with Hydro’s Wireless Condition Monitoring Solution are:

- Real-time data – not dependent on the next route cycle

- High-frequency data collection – no more missed events or issues

- Increased safety resources available for data analysis – reducing in-field data collection time increases availability for analysis

- Customizable alerts and alarms give users the assurance to operate their machines without concern

- Maintenance schedules can be optimized based on machine condition

For over 50 years, Hydro has been providing customers with creative engineering solutions to complex pump problems. Now, Hydro offers 360° support for customers’ rotating machinery with Centaur: Hydro’s Wireless Condition Monitoring Solution.

Do you have concerns regarding your critical asset reliability? Visit https://hydroinc.com/centaur or call 1-800-223-7867 to learn more about Hydro’s suite of services.

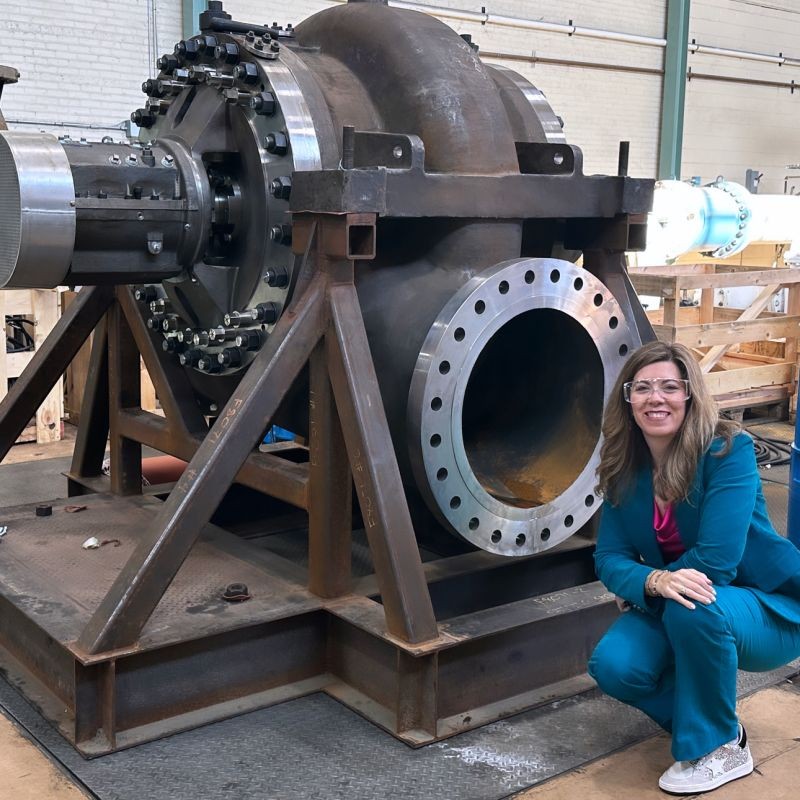

We agree with Empowering Pumps, pump testing and condition monitoring are the coolest!

We agree with Empowering Pumps, pump testing and condition monitoring are the coolest!

Ever wondered how to better understand equipment health but struggled with climbing the mountain of data available to come up with actionable information?

Ever wondered how to better understand equipment health but struggled with climbing the mountain of data available to come up with actionable information?