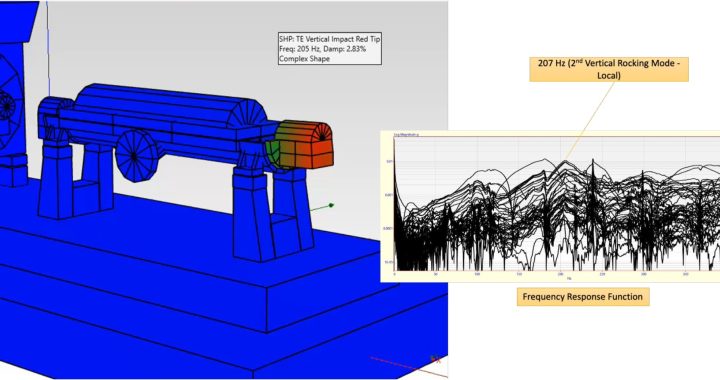

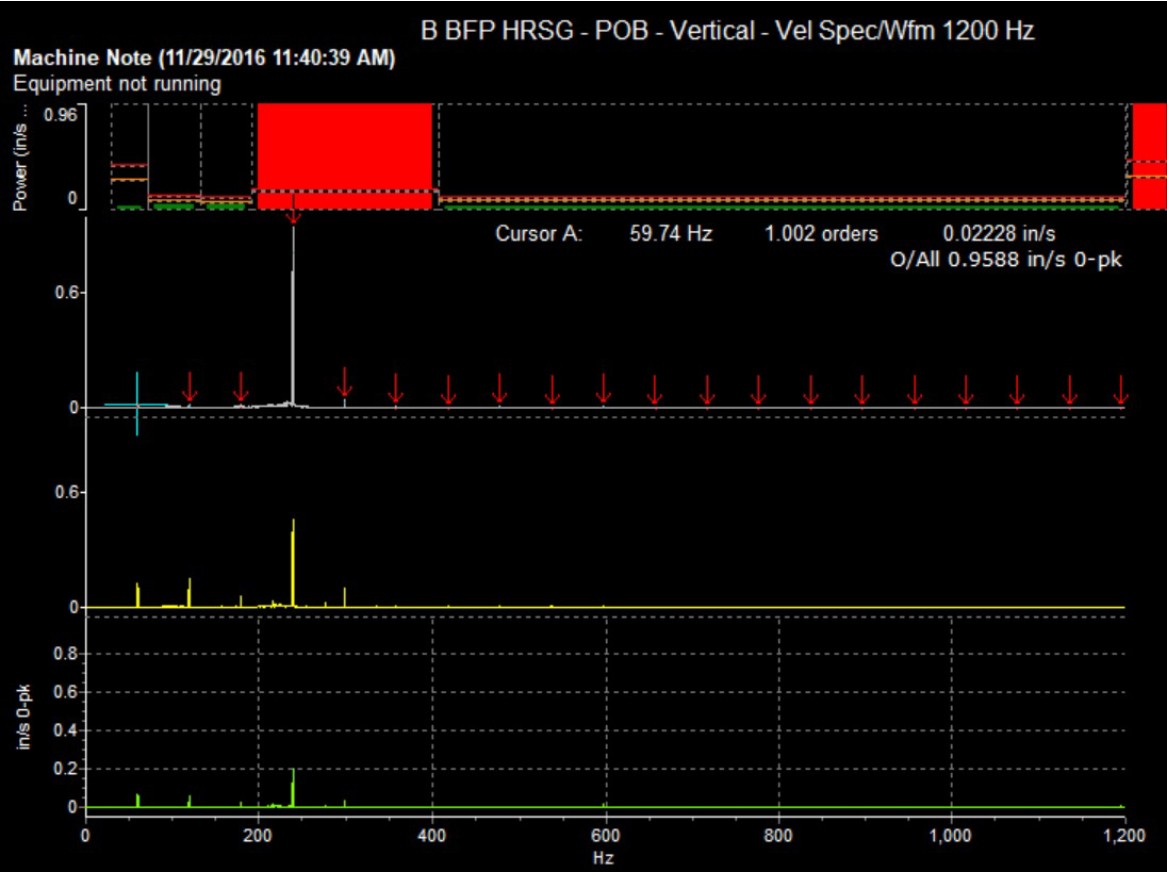

Vertical pumps are especially susceptible to minor conditions that can result in elevated vibration amplitudes. The vertically suspended design and long stationary element lengths often combine into natural frequencies that are near forcing frequencies, such as running speed or even sub-synchronous faults. The complexity of these issues makes it difficult to diagnose and resolve persistent vibration issues with the type of data that is routinely available to the end users.

In-depth field testing paired with computational analysis provides a clear path to both an accurate diagnosis and a solution that has a high likelihood of success. The effectiveness of this methodology was proven for a Gulf Coast midstream company who was experiencing high vibration with their vertical freshwater pumps. By applying advanced field diagnostics, the end user was able to understand the underlying causes of the vibration and evaluate possible solutions in a theoretical environment prior to implementing them in the field.

In-depth field testing paired with computational analysis provides a clear path to both an accurate diagnosis and a solution that has a high likelihood of success. The effectiveness of this methodology was proven for a Gulf Coast midstream company who was experiencing high vibration with their vertical freshwater pumps. By applying advanced field diagnostics, the end user was able to understand the underlying causes of the vibration and evaluate possible solutions in a theoretical environment prior to implementing them in the field.

Read the full case study, published in the May 2025 edition of Pumps & Systems magazine, here.

Read more case studies on vibration analysis and the work completed by Hydro Reliability Services here.