In this webinar, instructor Dr. Gary Dyson will present a foundational overview of essential hydraulic principles and explain how they influence pump performance in practical operating conditions.

Tag Archives: Gary Dyson

Webinar: Pump Hydraulics Broken Down!

Did you miss Gary’s discussion of pump hydraulics earlier this year? You’re in luck! We are rerunning this popular topic in a partnership with Pumps & Systems magazine.

Join instructor Dr. Gary Dyson as he discusses how fluid movement has consequences for pump reliability.

Join Our Lecture | 2025 Turbo Pump Symposia

Hydro is proud to be presenting again at the 2025 Turbo Pump Symposia in Houston, TX! Join presenters Dr. Gary Dyson and Freddy Cardenas Linero as they discuss a case study where advanced engineering was used to dramatically increase flow of a shipping pump in an oil and gas terminal facility.

Wednesday, September 17, 2025 | 2:00 – 2:45pm | Room 370A

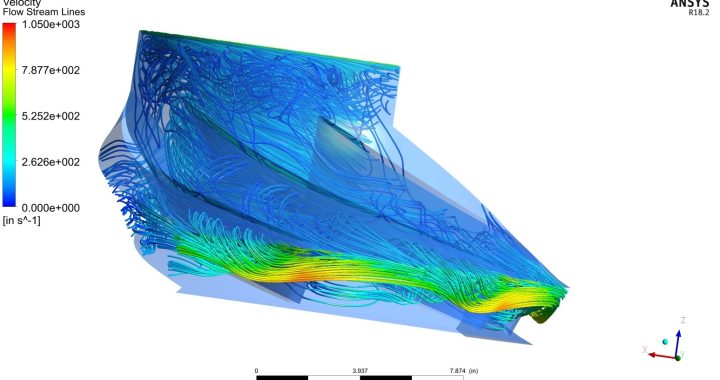

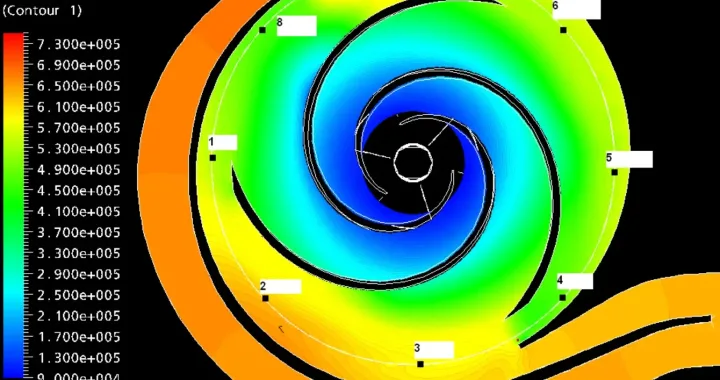

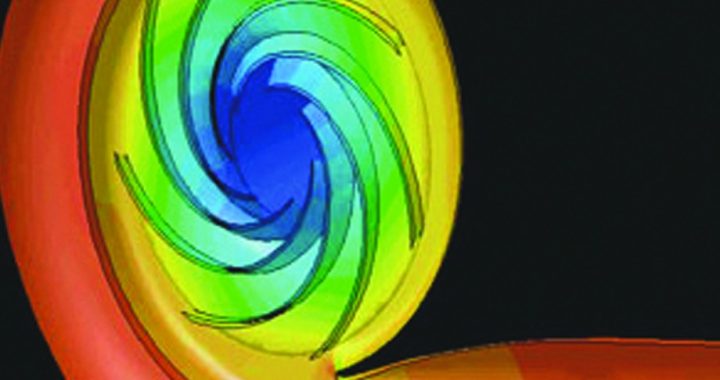

Centrifugal pumps are critical to fluid handling systems, but as operational demands evolve, optimizing performance becomes essential. This lecture will present a successful hydraulic re-rate of a propane shipping pump (P-1010) at Phoenix Park Gas Processors’ Hull facility in Texas, aiming to double railcar loading capacity without major system modifications. Instead of replacing the pump, a process requiring over 40 weeks of lead time and costly infrastructure changes, the project used a duplicate unit sourced from the aftermarket. It was reverse engineered, hydraulically redesigned, and optimized using CFD simulations to shift the Best Efficiency Point from 350 GPM to 800 GPM while reducing head by 60%.

The study highlights the importance of combining CFD analysis with mechanical evaluation to ensure reliable performance. It outlines a structured methodology from feasibility assessment to installation, including modeling, manufacturing, quality control, and commissioning. This project demonstrates how a targeted hydraulic re-rate can extend equipment life, increase throughput, and reduce energy use and capital costs, all while maintaining existing mechanical and system constraints.

Find out more about this year’s Turbo Pump Symposia here.

Learn more about Hydro’s Engineering Services.

Empowering Pumps Sustainability Summit

Hydro was proud to participate in this year’s Empowering Pumps virtual Sustainability Summit. This year’s summit explored the vital intersection of environmental responsibility and industrial innovation in the pump and equipment industry.

The summit featured prominent voices including Hydro’s Dr. Gary Dyson, who champions innovative pump design and modification. Gary was joined by Tomas Dobrovolskis of Hidrostal North America, recognized for groundbreaking sustainable equipment solutions and Todd Bush of Decarbonfuse, a leader in industrial decarbonization strategies.

The discussion, led by Empowering Pumps & Equipment President, Vince Marino, shared perspectives on a more sustainable future in industrial operations, highlighting how companies are transforming their approaches to sustainability through cutting-edge product design, sophisticated manufacturing processes, and purposeful operational improvements.

You can watch this year’s summit here:

Learn more about Empowering Pumps and Equipment here.

Read more about Hydro’s commitment to sustainability and how we help end users achieve energy savings through Hydro Energy Edge.

Wednesday Webinar: Pump Hydraulics Broken Down!

Join us for our June webinar, where Dr. Gary Dyson breaks down pump hydraulics and their effect on pump health and performance. Learn how fluid movement has consequences for pump reliability.