Join instructor Mike Mancini as he explores how to determine where your equipment is running relative to the best efficiency point and how to use this information to optimize operation. This will include a discussion of pump curves, system curves, and detecting performance degradation using field data. Strategies for achieving peak efficiency and the benefits of these actions will also be discussed.

Tag Archives: energy edge

Lecture: Energy and Reliability Savings on Pump Equipment- A Comprehensive Approach

Join Hydro at the Turbo Pump Symposia as we co-present with Petroleum Development Oman on how energy and reliability savings can be achieved on pump equipment.

Presentation authors include Dr. Gary Dyson and Freddy Lineros of Hydro, Inc and Paul Willcox of Petroleum Development Oman.

The presentation will be held from 2:00pm to 2:45pm on Wednesday, August 21, 2024 in Room 370A.

Lecture Focus:

The costs associated with operating and maintaining an extensive fleet of oil pumping equipment are significant. The equipment consumes a large amount of power, it operates in harsh conditions and the production requirements mean that reliability is important. The equipment is responsible for large amounts of oil revenue that is essential to the Oman economy.

The combination of these aspects means that there is a great opportunity to minimize the cost of oil production and maximize oil production by ensuring equipment is exactly matched to the demand.

Further to this, there is also the environmental impact of the CO2 generated by the power needed to operate the equipment. As the leading energy producer in Oman, Petroleum Development Oman (PDO) has refreshed its strategy, so it is suited to a dynamic energy landscape with a new focus on creating value, driving sustainability and advancing renewable energy initiatives while expanding their presence in the oil and gas sector. Environmental sustainability is therefore of the utmost importance to PDO and the reduction in CO2 emissions based on reduction of consumed power is significant both environmentally and from a cost standpoint.

The philosophy employed by PDO for reducing emissions and modifying equipment for power saving, operational availability and reliability is outlined in this presentation along with illustrating how the system-based approach has led to major cost savings.

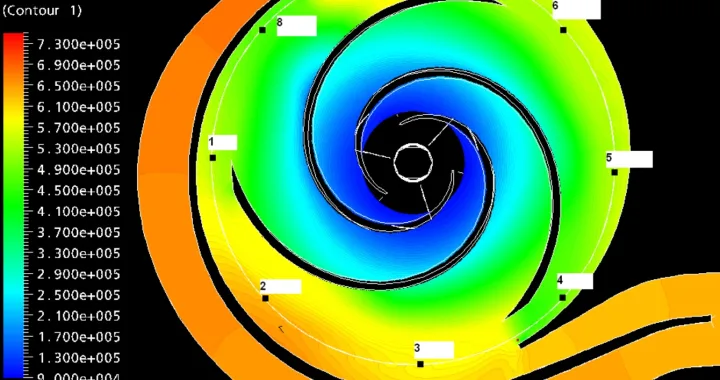

Two examples of modifications made to high energy pumping equipment to reduce the power consumption are outlined, alongside the associated technical challenges. The approach considers the operating regimes, the pump system interaction and the long-term operating requirements of the equipment. These requirements flow into the design process to re-rate the equipment with new hydraulics performance and impellers designed using CFD to match the system and operational requirements. The design process not only considers hydraulic performance but also uses the time dependent nature of the flow to evaluate changes in vibration caused by the modified designs.

Reliability of the equipment is also considered as the pump operating regime moves close to BEP at all conditions.