In this webinar, instructor Dr. Gary Dyson will present a foundational overview of essential hydraulic principles and explain how they influence pump performance in practical operating conditions.

Tag Archives: CFD

White Paper: Performance Prediction for the Aftermarket

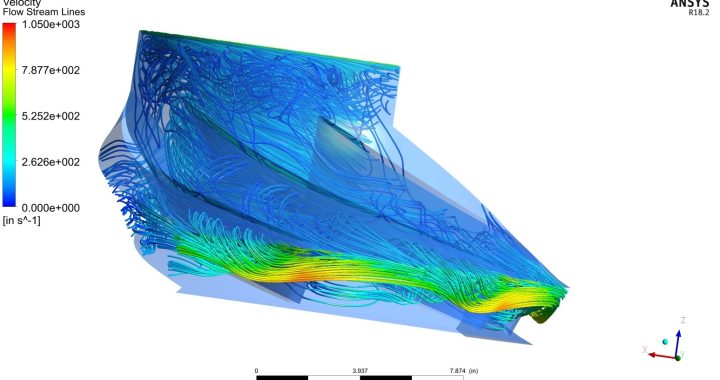

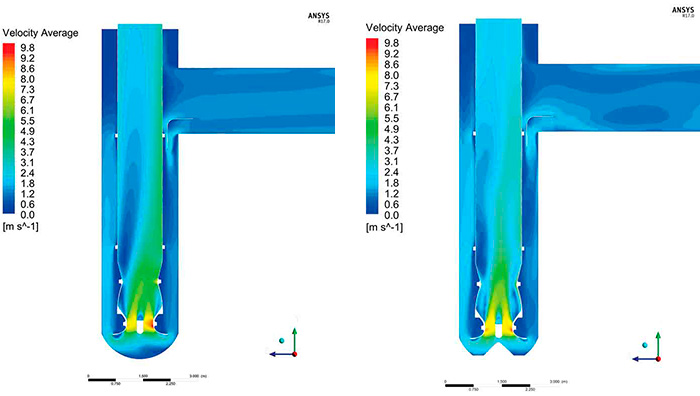

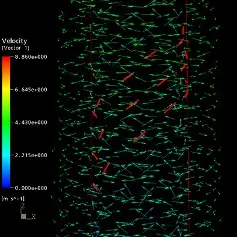

Pumps are often expected to run at low flows and on many occasions can spend their entire operating lives there. It is important to understand the complex behavior of fluid and how that affects performance and reliability so that modifications can be made to achieve optimal performance in these challenging conditions.

By combining reverse engineered data, analytical tools and engineering expertise, a comprehensive approach can be developed to understand and modify hydraulic performance. This process allows pumping equipment to function exactly as required by the system that it fits within.

By combining reverse engineered data, analytical tools and engineering expertise, a comprehensive approach can be developed to understand and modify hydraulic performance. This process allows pumping equipment to function exactly as required by the system that it fits within.

Download our latest white paper published with Pumps & Systems magazine to read Dr. Gary Dyson’s discussion of how low flow affects performance and what can be done to optimize operation and reliability.

Learn more about Hydro’s engineering services.

Using Latest Technology to Refurbish a 50-year-old Pump Element

Power pump performance improved with redesign of the first-stage, double-suction impeller and twin volute.

This project has been divided into two articles. The first, published in the June 2017 Pumps & Systems; the second, published in September 2017 Pumps & Systems.

Written by: Dave Allard & Dr. Gary Dyson

Published by: Pumps & Systems

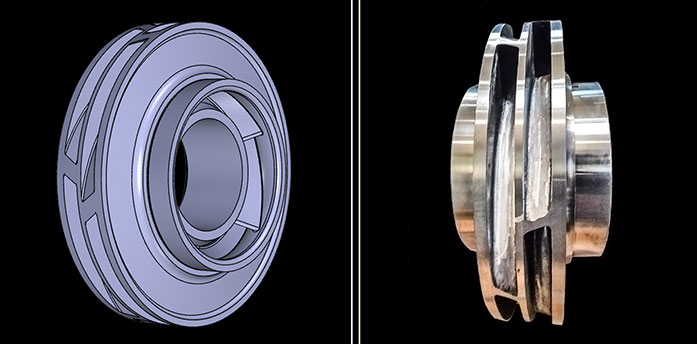

In the aftermarket business, part replication is not enough. Precision engineering combined with the latest technology are essential for manufacturing high-quality parts. A main boiler feed pump at a Midwestern United States power plant was built in 1967 using sand casting and wooden patterns, now considered outdated technology. Even though the pumps received refurbishment every six to eight years, the pumps continued to have low performance as well as vibration issues.

Using all its resources—including casting simulations, 3-D models, up-to-date foundry casting techniques and considerable engineering data—Hydro fully manufactured a complete element, performed sophisticated testing in the Pumps Test Lab Approved Program (PTLA) certified test lab, and returned the pump to operation within just 12 weeks.

This project involved the manufacture of a complete first stage twin volute and a description of the latent defects.

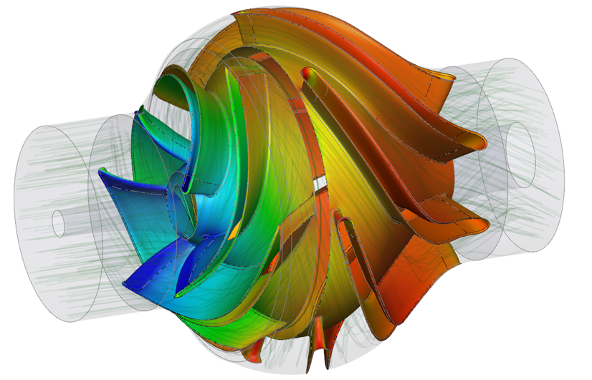

The pump suffered from ongoing vibration issues which were caused by pressure pulsations at vane frequency. To improve the vibration levels, hydraulic analysis and redesign were required to develop a new, improved design.

This project has been divided into two articles. The first is the manufacturing of the twin volute and the second is the design of a new impeller.

Image 1. A received bundle showing failure in the twin volute stage piece. Hydro received the internal element and casing (pump bundle, or element) of the pump. (Images and graphics courtesy of Hydro, Inc.)

The first-stage twin volute is a complicated casting, which failed during operation as a result of poor design.

Hydro re-engineered the casting by using sophisticated engineering and 3-D modeling, along with simulation software and 3-D sand printing.

In addition, Hydro identified the opportunity to improve the performance of the pump by redesigning the first-stage double-suction impeller. To improve vane passing frequency, the first-stage double suction impeller was redesigned with staggered and split vanes.

Hydro’s aftermarket services capability provided a completely new replacement element for this high-energy boiler feed pump and also redesigned the castings to eliminate the original latent defect in the casting design.

Hydro provided sophisticated hydraulic engineering improvements to increase the mean time between repairs (MTBR) of the newly manufactured element.

Hydro Inc. is Carving out their Niche in the Global Pump Aftermarket

Written by: Sarah Schroer

Publisher: Pump Engineer / June 2015

Pump Engineer spoke with George Harris, Hydro Inc.’s CEO and Founder, to learn more about what sets them apart from other pump aftermarket services. “Hydro has developed a unique niche where we have the capabilities, the engineering support, and the lab for testing purposes to provide comprehensive support for customers, while providing prompt capable service on a global basis,” says Harris. Hydro Inc. makes customers the cornerstone of their business. “Everything that we do is focused on the needs of the customer,” explains Brian Scorer who is the Executive VP at Hydro Inc. “We make sure we are entrepreneurial, fl exible, agile, and very quick in the way that we go about our business. We provide world class quality, world class delivery, and we wish to be competitive on cost. The foundation for what we do is built upon engineering excellence and technology. We also have some of the world’s best pump engineers.”

Werner Barnard and Dr. Gary Dyson of Hydro, Inc.

Shortcuts Can Lead to Disastrous Outcomes

Design flaws cause catastrophic failure in a geothermal power station hotwell in New Zealand.