Pulp and Paper Industry Pump Repair

- Case Study Summaries

- Ahlstrom Make-Up Liquor Pump

- Byron Jackson Process Water Pump

- Sulzer Boiler Feed Water Pump

- KSB Boiler Feed Water Pump

- Sulzer Headbox Feed Pump

Repair is an Opportunity for Improvement

Worldwide competition in the pulp and paper industry make quality and reliability more important than ever. Having developed a culture of quality and reliability throughout our organization, Hydro has provided a range of pump repair, engineering and support services to the pulp and paper industry since 1969.

Click on any of the links to the left to learn more about our experience in improving the performance and reliability of your pumps.

Ahlstrom Make-Up Liquor

Application: Make-Up Liquor

Pump Details: Ahlstrom Model 2LRS-20

Pump Type: 2-Stage Overhung

When a pulp mill's make-up liquor pump failed, Hydro's standard disassembly and inspection process uncovered a path for abrasives to reach the wear rings. Heavy localized wear was identified at the casing, behind the casing wear ring. In addition, there was excessive leakage of the seal water and black liquor. The millwrights were unable to properly adjust the packing gland because the 2-bolt packing gland follower was cocked on the studs due to the high pressure of the seal water. This misalignment also caused significant wear to the diffuser vane tips.

Hydro manufactured new wear rings without slots to prevent the abrasive material from damaging the case and to minimize wear behind the casing wear rings. The worn areas of the casing and a new sleeve were overlaid with tungsten carbide to prevent further damage. Hydro designed and machined a 4-bolt split packing gland follower to help maintain alignment of the packing gland follower with the stuffing box. A special material was installed to help cool and lubricate the seal to allow the proper distribution of seal water.

The diffuser vane tips were welded to restore them to their pre-wear length and the impellers were balanced to a stringent level of 2 W/N. This engineered rebuild provided improved reliability for this pump.

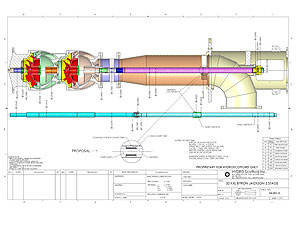

Byron Jackson Process Water

Application: Pond Process Water

Pump Details: Byron Jackson 32KXL

Pump Type: Multi-Stage Vertical

Industrial pumps are sometimes repaired or modified by smaller local repair shops that do not have the engineering oversight to ensure that the repairs and modifications meet the original design's intent. When Hydro received this pump, it was clear that prior modifications which had been performed without engineering review were causing problems.

This pump had been “upgraded” by replacing the upper bearing with an enclosure tube, which was not part of the original design. The lack of that bearing contributed to the instability of the top shaft and may have lead to the pump's failure.

After fully reverse engineering the pump, Hydro redesigned the existing enclosure tube to incorporate the missing upper bearing. The modification involved machining the enclosure tube into two pieces and joining them together with a coupling and adding a bushing to stabilize the shaft.

Because the spare parts provided were of an older design and no longer fit the pump, Hydro manufactured several parts. These included a new transition piece, diffusers, a new bearing, and suction bell. Moreover, the impeller vane tips were weld-repaired and re-machined, and the impellers were then balanced to 4 W/N. The pump, which was rebuilt to standard specifications and reconstructed using a durable stainless steel, was ret

Sulzer Boiler Feed Water

Application: Boiler Feed Water

Pump Details: Sulzer 4x6x10.5 MSD 4-Stage

Pump Type: Multi-Stage Horizontal Split Case

Upon inspection of the paper mill's failed boiler feed pump, Hydro determined that the pump seized due to loss of the thrust bearing. Though the failure caused extensive damage to the pump, Hydro rebuilt the pump with upgrades to improve rotor stability, protect the pump against dry run conditions, and improve the overall efficiency.

Hydro reverse engineered the shaft, which had been damaged by excessive heat and wear on the thrust bearing end, and manufactured a new one from a more durable stainless steel. Hydro also manufactured new impeller wear rings and case rings from upgraded material. All stationary wear components, except the throat bushing, were manufactured with composite materials to improve rotor stability. Rotor stability is greatly improved due to the reduced running clearances that are possible with composite materials - typically clearances can be reduced by 50%.

The first stage impeller was weld-repaired, stress-relieved, and machined back to standards. The clearance between the case and stationary components was returned to OEM standards. The impellers were individually balanced, then the assembled rotor was balanced to 2 W/N.

KSB Boiler Feed Water

Application: Boiler Feed Water

Pump Details: KSB Model HGC 4/6

Pump Type: Ring Segment 1500hp

A KSB boiler feed pump in service at a paper mill suffered a catastrophic failure due to a dry run event. Having dismantled the pump and performed a complete inspection of the internal components, Hydro confirmed that the impellers and diffusers were severely damaged and the wear rings were broken. The pieces which broke away from the impellers and diffusers had damaged the inside of the casing as they moved through the pump.

Four of the six diffusers had vanes which were so badly damaged they could not be repaired. Hydro manufactured new diffusers and impeller wear rings from a durable stainless steel and upgraded the bolting material that holds the diffusers to the stage casing. To help the pump survive another temporary dry run situation, the case rings were fitted with composite inserts and tack welded back into place to reduce corrosion damage.

Hydro rebuilt this pump with engineered upgrades, and since being installed at the mill over a year ago, it has been their best running pump.

Sulzer Headbox Feed

Application: Headbox Feed

Pump Details: Single-stage Sulzer ZPP 800

Pump Type: Double-suction Horizontal Split Case

After years of useful service, casings of many horizontal split case pumps are quite worn and no longer meet the original specifications. Hydro offers an alternative to purchasing a new OEM casing that offers a much lower cost and reduced turnaround time.

Due to their long-standing relationship with Hydro, a paper mill decided it was time to restore the casing of their headbox feed pump. Because this pump was in a critical application, the mill required a very short turnaround time.

To avoid a temporary shut down of the mill, Hydro was able to perform a line bore and insert upgrade within a period of three days. Utilizing around-the-clock shifts, Hydro completed the case inspection and developed machining fits and tolerances to restore the casing to its original specifications. Hydro then manufactured and mounted inserts to the casing.

Not only were the casing and wear components restored to their original fits, the upgraded materials will significantly improve mean-time-between-repair.