Many of our aging facilities are still using the pumps that were purchased and commissioned during plant construction. Despite the age of this equipment, effective maintenance strategies and upgrade opportunities can extend useful life for decades more. Older pumps are often more robust than current designs, which take advantage of new manufacturing technologies to reduce the raw materials needed for construction. However, vintage equipment has its downfalls as well. It is important to understand the challenges we face when operating and maintaining vintage equipment so that we can stay ahead of potential sources for decreased reliability.

Many of our aging facilities are still using the pumps that were purchased and commissioned during plant construction. Despite the age of this equipment, effective maintenance strategies and upgrade opportunities can extend useful life for decades more. Older pumps are often more robust than current designs, which take advantage of new manufacturing technologies to reduce the raw materials needed for construction. However, vintage equipment has its downfalls as well. It is important to understand the challenges we face when operating and maintaining vintage equipment so that we can stay ahead of potential sources for decreased reliability.

These challenges were at the forefront of an improvement project undertaken by a Canadian pulp mill. Most pulp and paper mills in North America have been in operation for decades, and many are still running with the original equipment. This facility had several BB2-style makeup liquor pumps (MULP) that were experiencing a low mean-time-between-failures (MTBF). To increase pump life and reduce the risk of unexpected downtime, the pulp mill approached Hydro’s Scotford service center for support in identifying the root causes of degradation. Hydro Scotford combined a thorough inspection process with experience in upgraded designs and materials to bring the MULP system reliability back to an acceptable level and improve overall performance. The major focus points of this project – standardization, material upgrades, and improved tolerances – can be applied to aging installations in all industries.

Read the full story in our recent case study published in World Pumps magazine.

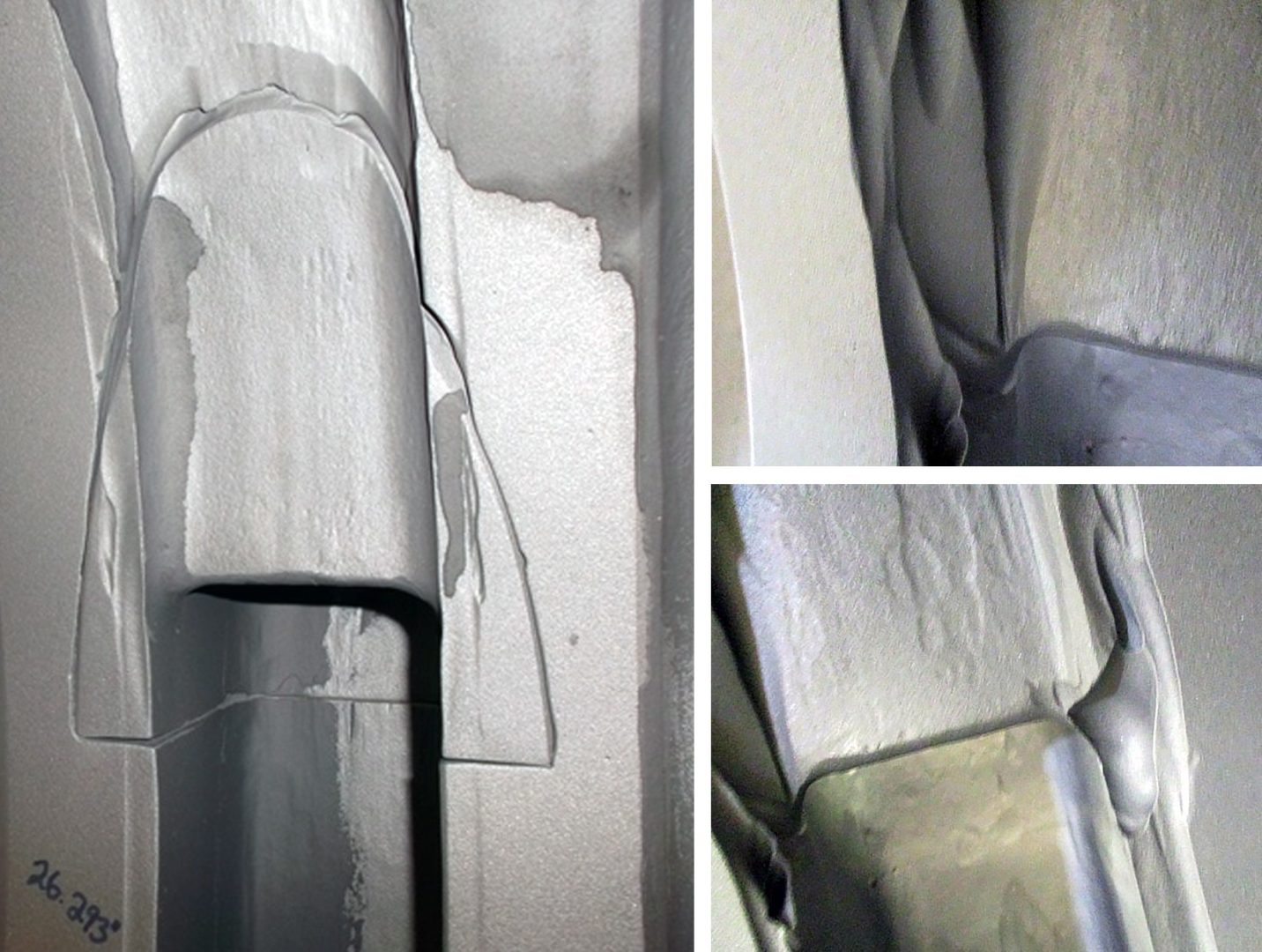

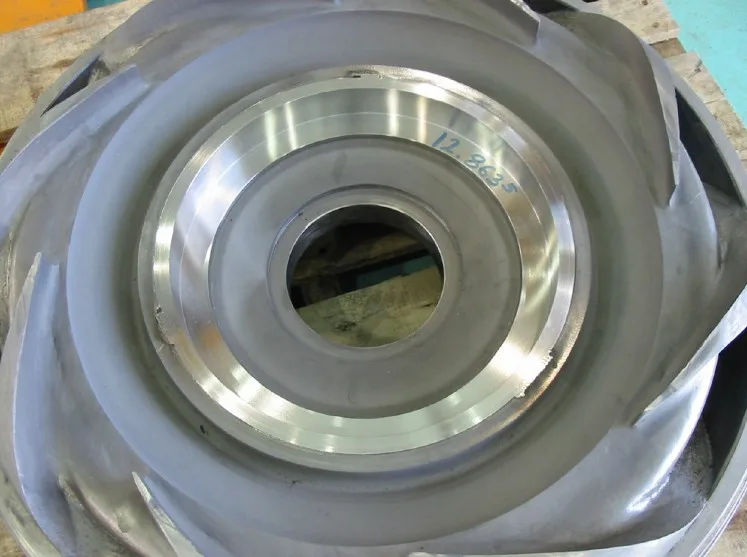

Hydro manufactured new wear rings without slots to prevent the abrasive material from damaging the case and minimize wear behind the casing wear rings. The worn areas of the casing and a new sleeve were overlaid with tungsten carbide to prevent further damage.

Hydro manufactured new wear rings without slots to prevent the abrasive material from damaging the case and minimize wear behind the casing wear rings. The worn areas of the casing and a new sleeve were overlaid with tungsten carbide to prevent further damage.