Application: Pond Process Water

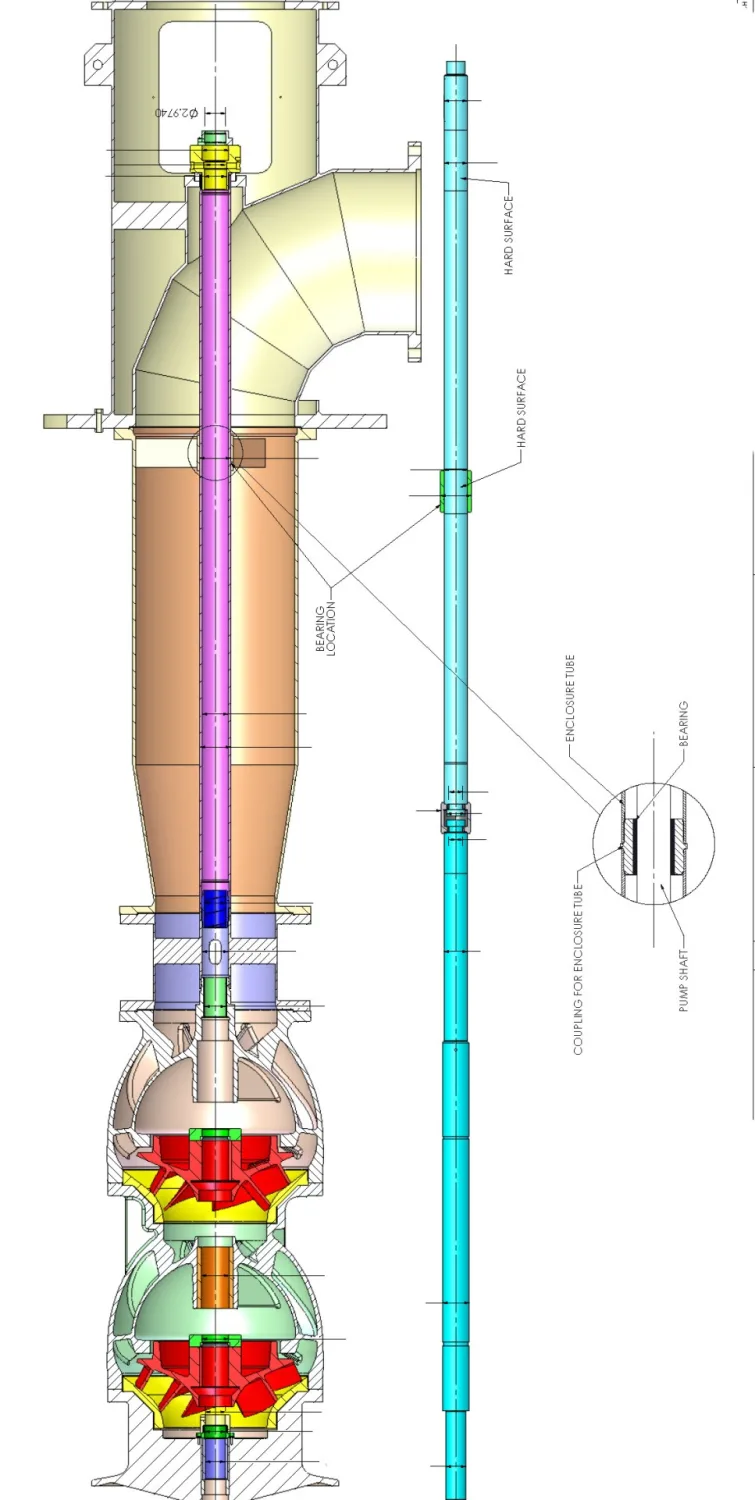

Pump Details: Byron Jackson 32KXL

Pump Type: Multi-Stage Vertical

Industrial pumps are sometimes repaired or modified by smaller local repair shops that do not have the engineering oversight to ensure that the repairs and modifications meet the original design’s intent. When Hydro received this pump, it was clear that prior modifications that had been performed without engineering review were causing problems.

Industrial pumps are sometimes repaired or modified by smaller local repair shops that do not have the engineering oversight to ensure that the repairs and modifications meet the original design’s intent. When Hydro received this pump, it was clear that prior modifications that had been performed without engineering review were causing problems.

This pump had been “upgraded” by replacing the upper bearing with an enclosure tube, which was not part of the original design. The lack of that bearing contributed to the instability of the top shaft and may have lead to the pump’s failure.

After fully reverse engineering the pump, Hydro redesigned the existing enclosure tube to incorporate the missing upper bearing. The modification involved machining the enclosure tube into two pieces and joining them together with a coupling and adding a bushing to stabilize the shaft.

Because the spare parts provided were of an older design and no longer fit the pump, Hydro manufactured several parts. These included a new transition piece, diffusers, a new bearing, and suction bell. Moreover, the impeller vane tips were weld-repaired and re-machined, and the impellers were then balanced to 4 W/N. The pump, which was rebuilt to standard specifications and reconstructed using a durable stainless steel, was returned to service successfully.

Learn more about Hydro’s targeted upgrades for the pulp and paper industry here.

Lear more about Hydro’s Scotford service center, the service center that spearheaded this project, here.