It’s estimated that 85% of pumps are not optimized to their systems, costing end users both efficiency and reliability. To achieve operational excellence and reduce environmental impact, assessing and improving our systems is essential.

Many OEMs focus on the initial pump design and providing a higher peak efficiency. While this can provide energy savings, it misses some of the greatest gains available. With our history in developing solutions for the aftermarket, Hydro approaches energy efficiency differently. Our unique experience as a brand-agnostic company focused on end users’ existing installed equipment has provided us with insight into improving equipment performance by understanding how it operates as a part of the greater system. This has allowed us to provide significant energy savings for our partners, as shown in successful cases such as this case study published in World Pumps magazine.

Many OEMs focus on the initial pump design and providing a higher peak efficiency. While this can provide energy savings, it misses some of the greatest gains available. With our history in developing solutions for the aftermarket, Hydro approaches energy efficiency differently. Our unique experience as a brand-agnostic company focused on end users’ existing installed equipment has provided us with insight into improving equipment performance by understanding how it operates as a part of the greater system. This has allowed us to provide significant energy savings for our partners, as shown in successful cases such as this case study published in World Pumps magazine.

Hydro’s Energy Edge program takes advantage of our in-house engineering, field testing, remanufacturing, and parts capabilities to provide an end-to-end solution to improve energy usage and reliability. The process starts with getting the necessary design and operation data to perform a comprehensive analysis of current performance and identify opportunities for improvement. Depending on the findings, solutions can range from system operations recommendations to hydraulic modifications to a completely redesigned drop-in replacement. By providing a custom solution instead of an off-the-shelf replacement, Hydro not only optimizes performance, but minimizes cost, lead time, and risk by ensuring that the solutions fits into the existing equipment footprint.

Hydro’s Energy Edge program takes advantage of our in-house engineering, field testing, remanufacturing, and parts capabilities to provide an end-to-end solution to improve energy usage and reliability. The process starts with getting the necessary design and operation data to perform a comprehensive analysis of current performance and identify opportunities for improvement. Depending on the findings, solutions can range from system operations recommendations to hydraulic modifications to a completely redesigned drop-in replacement. By providing a custom solution instead of an off-the-shelf replacement, Hydro not only optimizes performance, but minimizes cost, lead time, and risk by ensuring that the solutions fits into the existing equipment footprint.

Some of the aspects of an energy optimization project may include:

- Energy Savings Audit: Field performance testing provides a performance baseline and identifies areas where improvements can be made

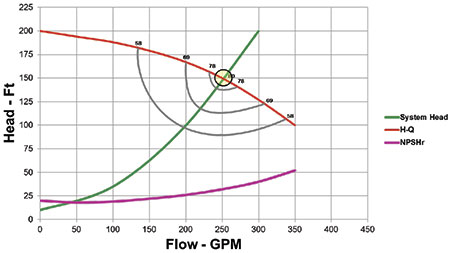

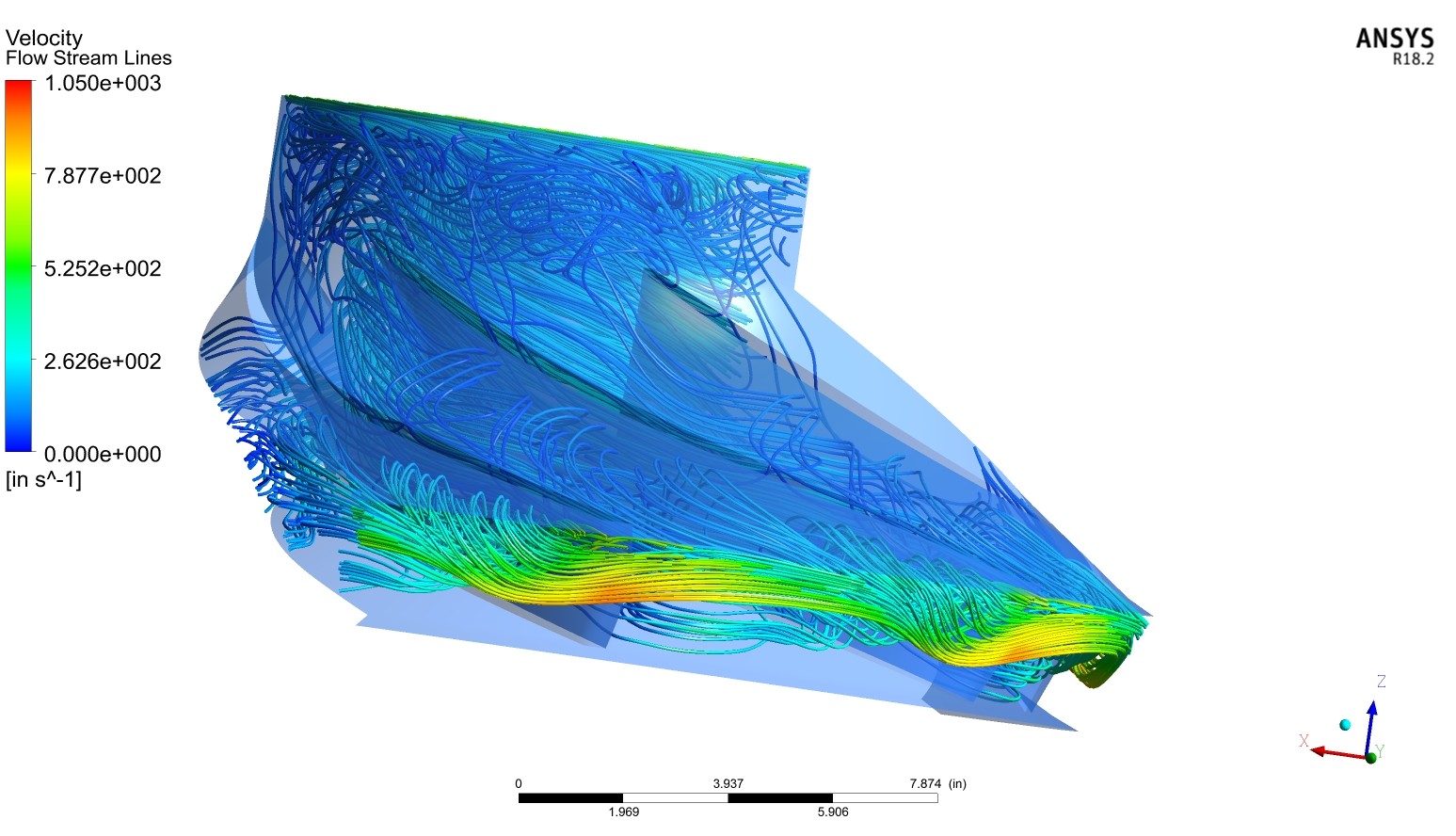

- System Analysis: Using system design experience and AFT Fathom hydraulic analysis software, Hydro’s engineers model and simulate fluid flow through the system to accurately predict system behavior and optimize performance.

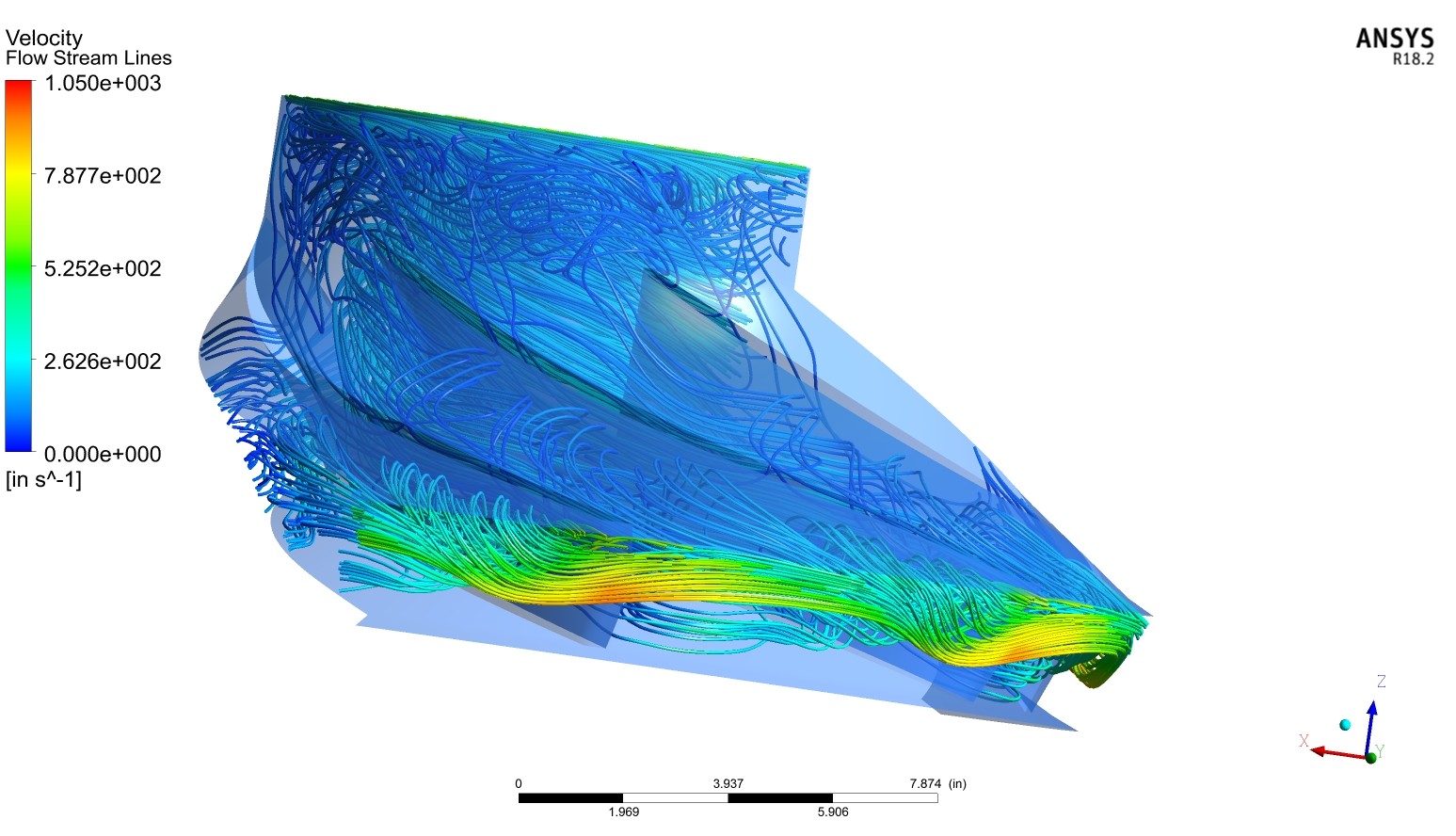

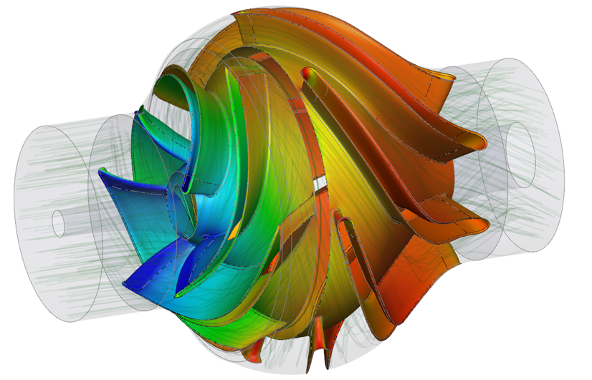

- Hydraulic Modification: Modification to existing hydraulic components or design of new components provides hydraulic performance optimized to meet system needs. Our hydraulic specialists use both design knowledge and CFD analysis to provide the best fit design for the application

- Equipment Remanufacturing and Parts Supply: Modifications are implemented through Hydro’s service center network, ensuring oversight and communication with the engineering design team. New cast parts are provided by our Parts Solutions division, ensuring control over parts quality and lead time.

- Performance Testing: Testing in our HI-certified performance test lab validates new hydraulics and provides a new certified performance curve. Post-modification field testing can also be performed to provide data on field performance.

- Continuous Monitoring: Using Hydro’s Centaur condition monitoring solution, equipment mechanical performance can be continuously monitored to provide better insight into equipment health into the future.

Want to learn more about energy efficiency and pump performance? Watch Bob Jennings’ presentation on the subject during Empowering Pumps 2024 Maintenance and Reliability Summit or read our co-authored eBook with Plant Services magazine.

By combining reverse engineered data, analytical tools and engineering expertise, a comprehensive approach can be developed to understand and modify hydraulic performance. This process allows pumping equipment to function exactly as required by the system that it fits within.

By combining reverse engineered data, analytical tools and engineering expertise, a comprehensive approach can be developed to understand and modify hydraulic performance. This process allows pumping equipment to function exactly as required by the system that it fits within.

Many OEMs focus on the initial pump design and providing a higher peak efficiency. While this can provide energy savings, it misses some of the greatest gains available. With our history in developing solutions for the aftermarket, Hydro approaches energy efficiency differently. Our unique experience as a brand-agnostic company focused on end users’ existing installed equipment has provided us with insight into improving equipment performance by understanding how it operates as a part of the greater system. This has allowed us to provide significant energy savings for our partners, as shown in successful cases such as

Many OEMs focus on the initial pump design and providing a higher peak efficiency. While this can provide energy savings, it misses some of the greatest gains available. With our history in developing solutions for the aftermarket, Hydro approaches energy efficiency differently. Our unique experience as a brand-agnostic company focused on end users’ existing installed equipment has provided us with insight into improving equipment performance by understanding how it operates as a part of the greater system. This has allowed us to provide significant energy savings for our partners, as shown in successful cases such as  Hydro’s Energy Edge program takes advantage of our in-house engineering, field testing, remanufacturing, and parts capabilities to provide an end-to-end solution to improve energy usage and reliability. The process starts with getting the necessary design and operation data to perform a comprehensive analysis of current performance and identify opportunities for improvement. Depending on the findings, solutions can range from system operations recommendations to hydraulic modifications to a completely redesigned drop-in replacement. By providing a custom solution instead of an off-the-shelf replacement, Hydro not only optimizes performance, but minimizes cost, lead time, and risk by ensuring that the solutions fits into the existing equipment footprint.

Hydro’s Energy Edge program takes advantage of our in-house engineering, field testing, remanufacturing, and parts capabilities to provide an end-to-end solution to improve energy usage and reliability. The process starts with getting the necessary design and operation data to perform a comprehensive analysis of current performance and identify opportunities for improvement. Depending on the findings, solutions can range from system operations recommendations to hydraulic modifications to a completely redesigned drop-in replacement. By providing a custom solution instead of an off-the-shelf replacement, Hydro not only optimizes performance, but minimizes cost, lead time, and risk by ensuring that the solutions fits into the existing equipment footprint.