Why look backwards when you can be looking forward?

The problems you inherited with your pump and system design shouldn’t be an anchor holding you back from stable operation. Hydro’s mission to increase pump reliability extends beyond our service facilities and into the field. Hydro Reliability Services provides expert troubleshooting, advanced engineering analysis, and field mechanical and hydraulic testing for your rotating equipment.

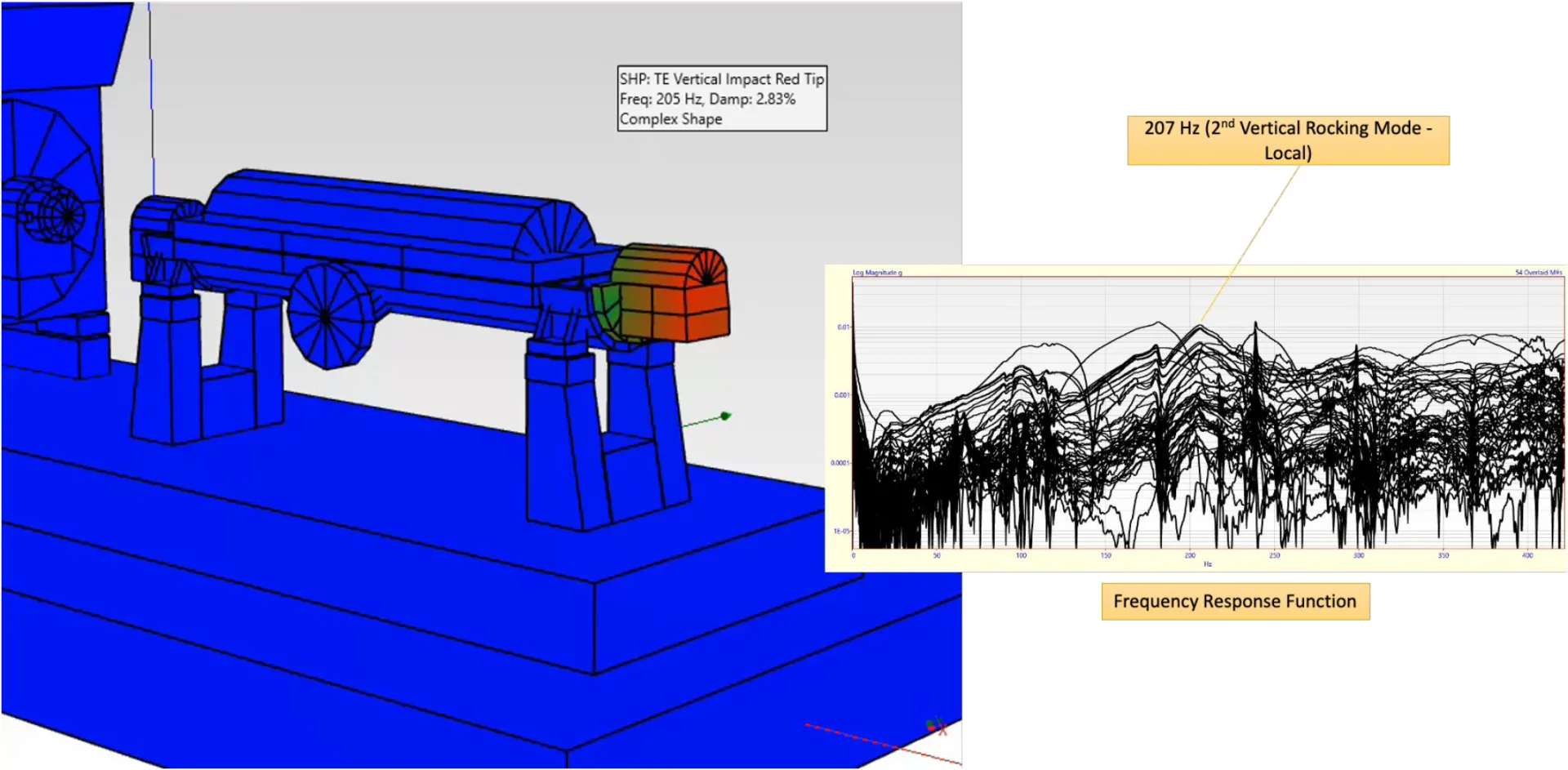

Many pump applications experience ongoing vibration and reliability issues; aging installations are also seeing margins between operation and resonant conditions eroding and previously reliable equipment being pulled into problems. The root cause of these problems is often resonance, a condition that is often misdiagnosed and commonly goes undiagnosed, resulting in persistent high amplitude vibration issues for long periods of time. Structural resonance typically results in highly directional vibration and increased amplitudes that can be difficult to resolve without the proper engineering approach. Fortunately, technology has developed to diagnose resonance and develop effective solutions without resorting to costly trial-and-error methods.

Many pump applications experience ongoing vibration and reliability issues; aging installations are also seeing margins between operation and resonant conditions eroding and previously reliable equipment being pulled into problems. The root cause of these problems is often resonance, a condition that is often misdiagnosed and commonly goes undiagnosed, resulting in persistent high amplitude vibration issues for long periods of time. Structural resonance typically results in highly directional vibration and increased amplitudes that can be difficult to resolve without the proper engineering approach. Fortunately, technology has developed to diagnose resonance and develop effective solutions without resorting to costly trial-and-error methods.

To help our customers solve complex problems with critical pumping equipment, Hydro Reliability Services’ engineers bring an array of technology to the site. Monitoring of traditional health indicators – flow, power, vibration, and pressure – is supplemented with advanced technology, such as Operating Deflection Shape and Experimental Modal Analysis. Leveraging their expertise and advanced modeling software, Hydro’s reliability engineers analyze this data to determine design and system weaknesses and propose improvements. This assessment gives you the ammunition you need to make an informed judgment about the risk of current and future operation.

Read our recent case study in Pumps & Systems magazine to learn more about how field testing and troubleshooting helped a power plant resolve a vibration issue in a critical application.

What does more effective troubleshooting mean for you?

- Maintaining a competitive edge in your marketplace through reduced operation and maintenance costs

- Creating a safer workplace with much lower risk of equipment-related accidents and reduced exposure to hazardous materials

- Contribution towards a sustainable future through more efficient operation and reduced risk of product leakage into the environment

- Ability to focus resources on proactive strategies and process innovation instead of continuously reacting to problem equipment