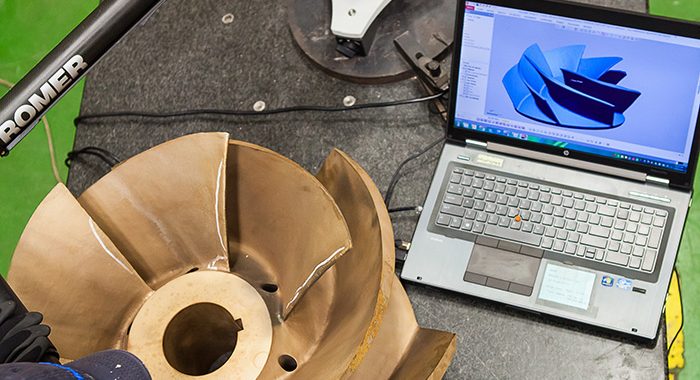

Hydro Middle East has a state-of-the-art manufacturing and service facility for comprehensive pump maintenance and rebuilding needs.

Hydro Middle East Inc. will provide aftermarket support for maintenance, rebuilds, retrofits, upgrades, re-rates, provide engineering support, conduct field service, and manufacture spare parts for PDO‘s entire centrifugal pump portfolio. Hydro Middle East has a state-of-the-art manufacturing and service facility for comprehensive pump maintenance and rebuilding needs.

Last year, Hydro Middle East and its agent Global Pavilion LLC were awarded a major 10 year contract by Petroleum Development Oman (PDO), the leading exploration and production company in Oman which is majority owned by the Government of Oman with Royal Dutch Shell, Total and Partex being the minority shareholders.

Hydro Middle East, the Dubai branch of Hydro Inc. group of companies having worldwide operations and headquartered in Chicago USA, has entered into a contract with PDO. With this contract, Hydro Middle East and its local partner Global Pavilion LLC will be responsible for a complete range of pump aftermarket services for both PDO’s high and low energy centrifugal pumps. In addition to the vital expertise that Hydro Middle East will provide to PDO, this contract also serves and supports the government’s initiatives to train young Omani engineers and utilize local resources within PDO local facilities.

Thomas Arakal, managing director of Hydro Middle East, noted that prior to Hydro’s arrival in the region, a need for high-level niche aftermarket engineering was not being served to industry here. “Hydro’s considerable engineering capabilities, along with ready and affordable access to our pool of experienced aftermarket engineers from our worldwide locations allow us to offer quick turnaround.”

George Harris, CEO of Hydro Inc. added, “With this new contract, Hydro looks forward to serving PDO’s needs while making an impact on young engineers in the region and helping to spread cutting-edge pump-engineering technology to this crucial region of the world.”

Hydro Middle East was established in Dubai’s National Industries Park with a state-of-the-art manufacturing and service facility for comprehensive pump maintenance and rebuilding needs. They are also licensed by American Petroleum Institute for drilling services (manufacture, service, testing, inspection of well control, pressure control and rig and drilling equipment, onshore and offshore).

Hydro has carved out a niche as the premier engineering and solutions based company for the oil and gas, power utility, nuclear, desalination, mining and petrochemical industries in the region.

Source: oilreviewmiddleeast.com

The Problem

The Problem