Reliability Services

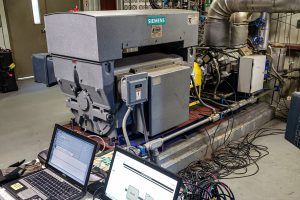

& On-Site DiagnosticsWith our highly skilled on-site reliability team, you can rest assured that your pumping systems will be in good health. Whether you need on-site troubleshooting for a complex condition or a routine field evaluation of your equipment, Hydro Reliability Services can provide comprehensive results to improve the performance.

One Source.

Total Support.

Worldwide.

Hydro Reliability Services provides expert troubleshooting and on-site engineering services for your rotating equipment. Hydro’s master pump improvement engineers work with your maintenance and engineering staff to provide complete reliability support for your pump installation base, whether the equipment is recently commissioned or has been in service for many years.

Providing On-Site Solutions for Complex Pump Problems

Hydro's highly skilled pump improvement engineers work with your maintenance and engineering staff to provide complete reliability support for your pump installation base, whether the equipment is recently commissioned or has been in service for many years.

To help our customers maintain critical pump equipment, Hydro's pump improvement engineers review the pump operating and maintenance history, provide a thorough on site inspection, and perform pump, driver, and system testing.

Hydro's Pump Improvement Engineers provide a multitude of vibration diagnostic services, ranging from minor issues, such as misalignment or imbalance, to very complex frequency analysis and testing such as natural frequency and finite element analysis.

Hydro's Reliability team, backed by Hydro's global network of service centers, provides assessments not just on your pump but the entire drive train. This testing is provided as either a troubleshooting service or a general health inspection of your equipment.

Comprehensive Reliability Service includes:

- Advanced Troubleshooting & Analysis

- Vibration Analysis

- System Related Issues

- Transient Event Diagnosis

- On-Site Pump Hydraulic Performance Testing

- Pump Capacity

- Total Dynamic Head (TDH)

- Brake Horsepower (BHP)

- Pump Efficiency

- Temperature Monitoring

- NPSH available

- Operating Deflection Shape

- Experimental Modal Analysis

- Finite Element Analysis

- Health Audits

Case Studies & Literature

Forensics

& Troubleshooting

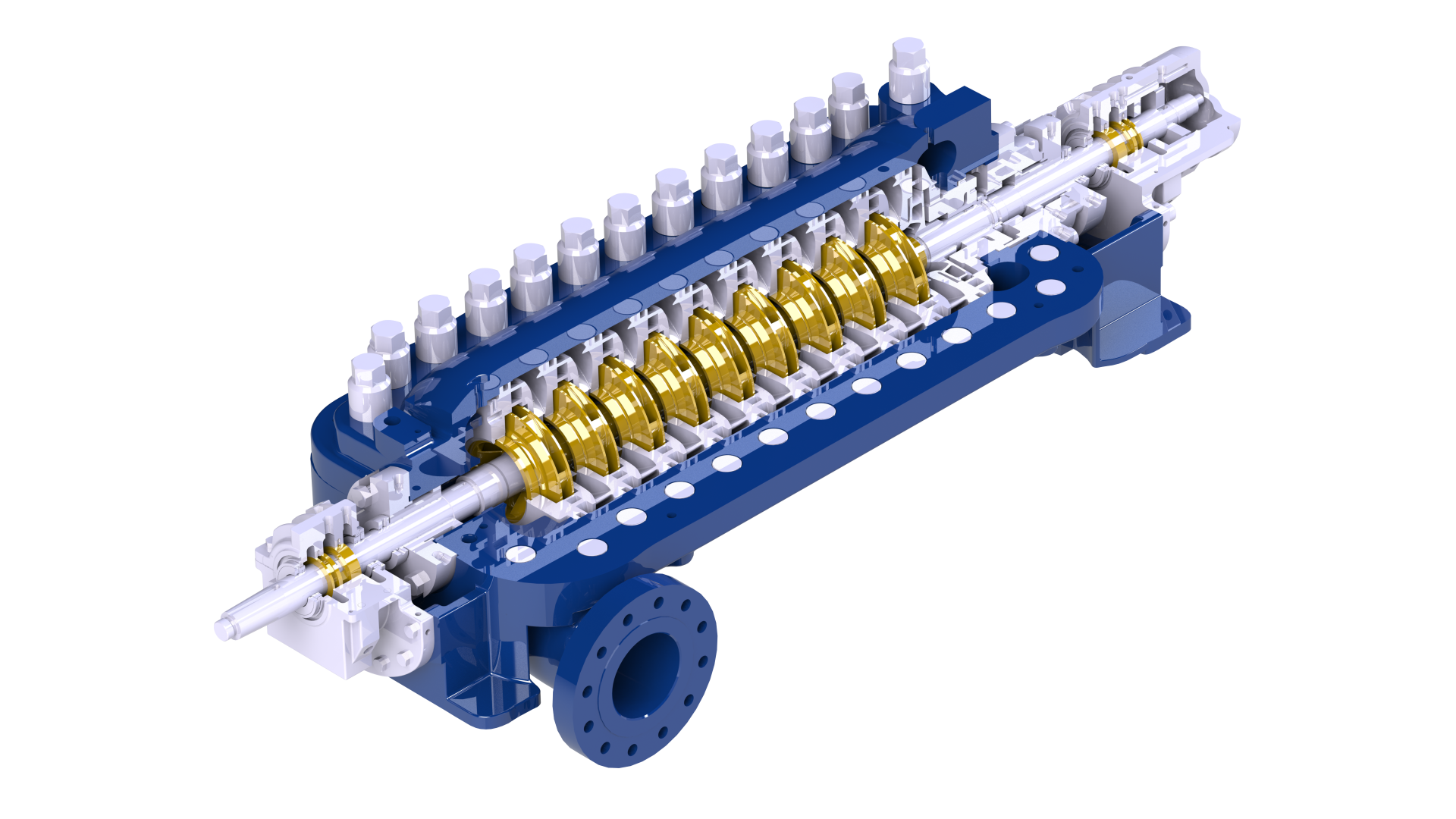

To help our customers solve complex issues with critical pumping equipment, Hydro’s Reliability engineers bring an array of technology to the site to help you get to the bottom of the issue. These issues may be related to a pump, gear box, motor, or operating system.

Hydro utilizes technology such as Operating Deflection Shape and Experimental Modal Analysis along with flow, power, and pressure monitoring. Hydro has the experience to resolve these issues.

Comprehensive

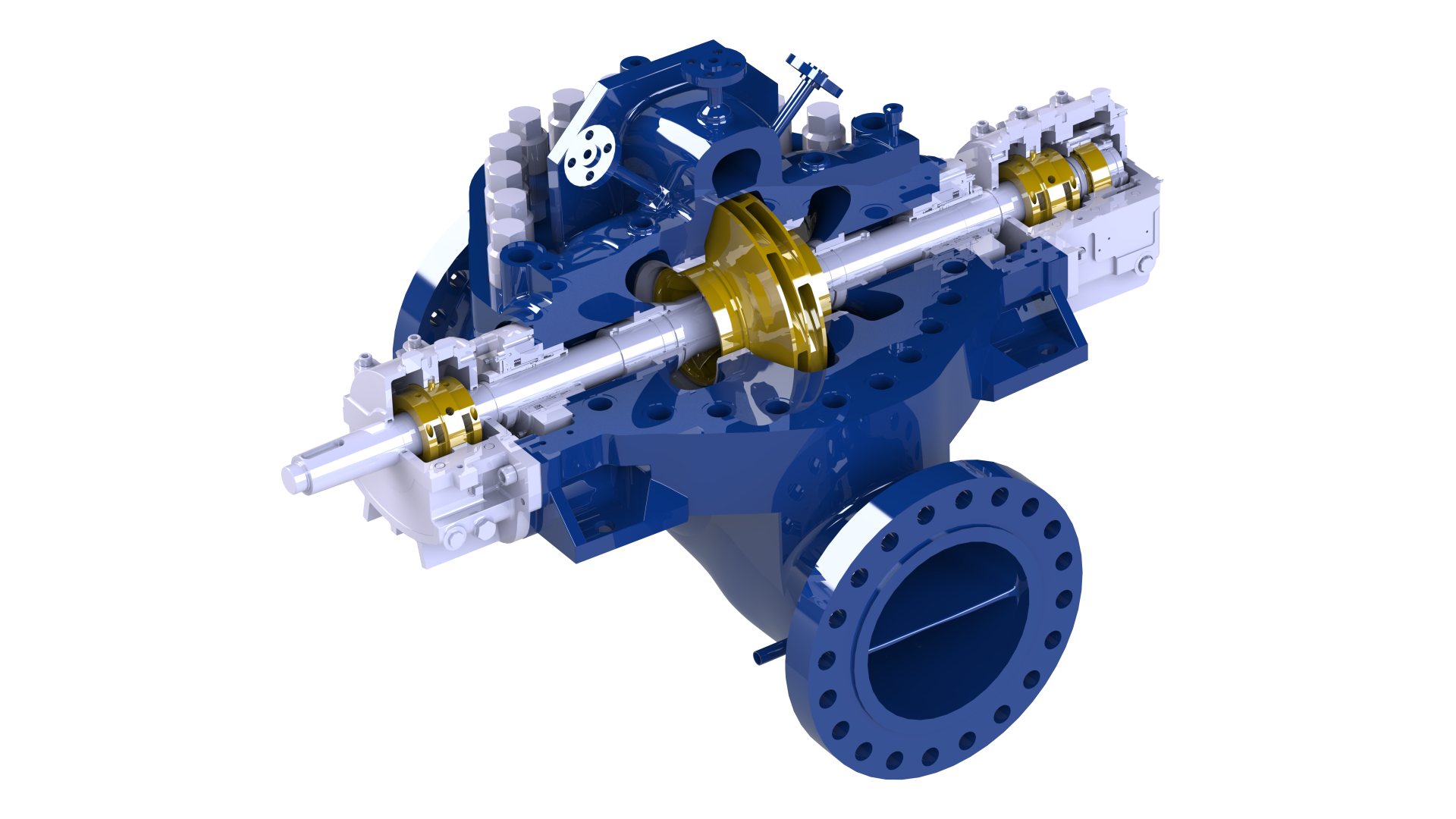

Health Audits

Hydro performs on-site health audits (or mechanical/hydraulic evaluations) on customer pumps and drivers. These audits include flow, vibration, temperature and mechanical condition inspections to help determine the overall condition of the equipment. These tests can be performed either before or after an equipment overhaul to help end users to better plan and prioritize for equipment down-time, as opposed to "running to failure.”

Uncover Underlying Issues With Your Critical Equipment

Hydro Reliability Services predictive and proactive approaches provide customers with troubleshooting and health audits to arrive at expert solutions for your rotating machinery challenges. Backed by over 50 years of experience, Hydro’s reliability engineers delve into the root-cause of pump issues and develop detailed job scopes for creating top-performing and long-lasting equipment. Being independent and unbiased allows Hydro to work on all makes and models of pumps.

Vibration Analysis

- Analysis of overall and peak values

- Analysis of discrete frequencies

- Resonance Testing

- Ramp Up/Coast Down Testing

- Gear Condition Analysis

- Bearing Condition Analysis

- High Resolution Data Collection

Pump Support Systems Analysis

- 'Piping & Layout

- Seal Flush/Injection

- Lubrication & Bearing Support

- Base Frame & Foundation

- AC Motor Diagnostics

Customer Success Story

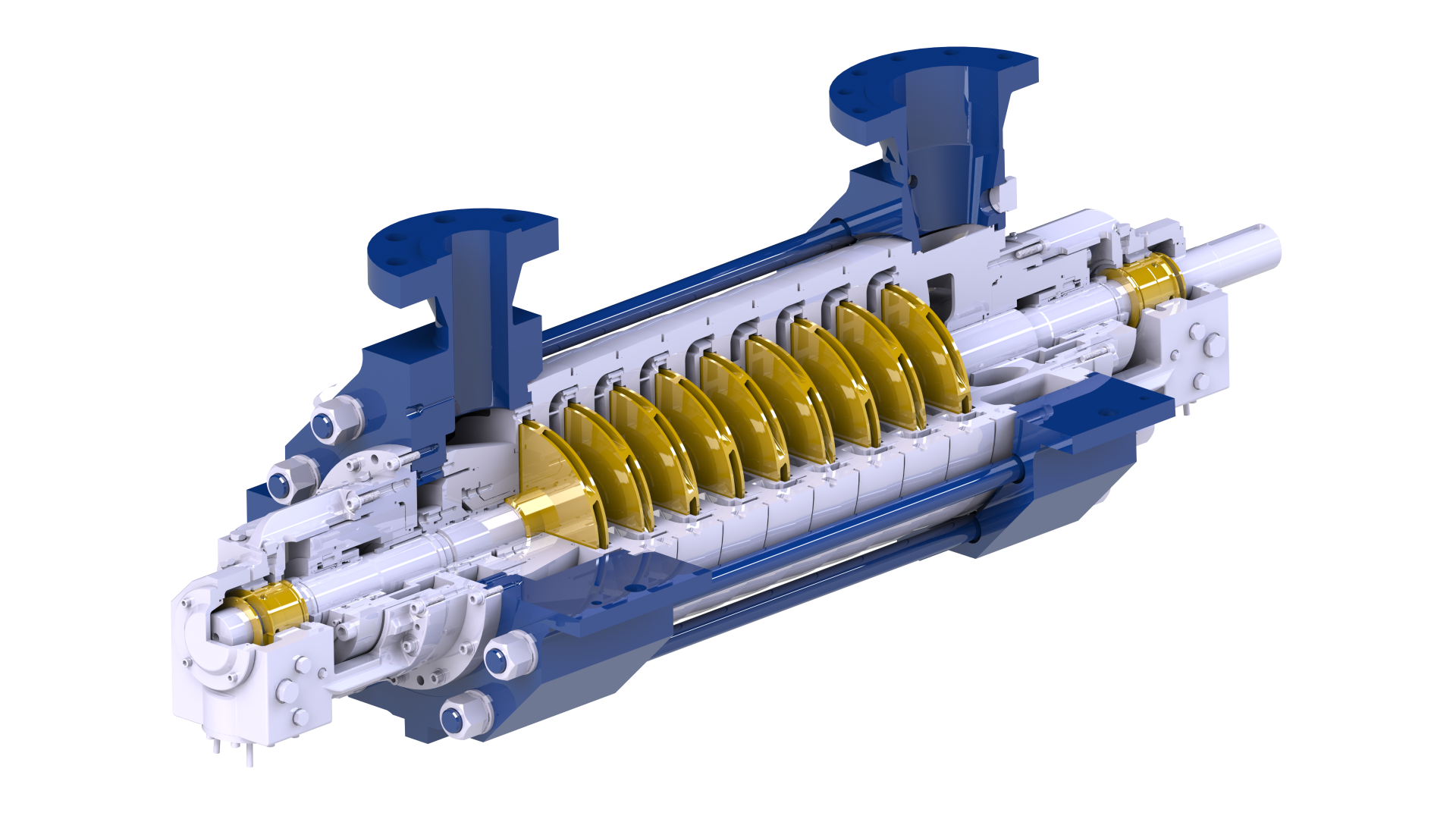

Hydro Reliability services was called into a combined-cycle plant to determine the condition of the plant’s two condensate pumps. Losing one of the pumps to failure would cause the plant to be vulnerable to unplanned downtime and huge expenses.

In concert with various Hydro divisions, Hydro Reliability Services was able to perform a health audit to identify performance issues, establish root causes to those issues using modal analysis, test solutions to the issues using finite element analysis, implement structural modifications to address those issues, test the effectiveness of those modifications using performance testing, and monitor performance of the pump in the field with wireless condition monitoring.

Hydro has the knowledge, experience, and technology to resolve these types of pump issues within the workshop and the field, which positions us as a total solutions aftermarket pump company.

Have a question?

For more information about how Hydro can support your rotating equipment needs, please fill out the contact form below.