During the last 20 years of my career, my main focus was on the refining and chemical industries. As I approached retirement last year, I was allowed to make some comments for Pump and Systems related to the problem facing those industries as it relates to the availability of “replacement parts” for pumps that have moved into the age range of 40 plus years; namely, we have a nationwide infrastructure problem if we do not find ways to extend the lives of hundreds of thousands of pumps by having parts availability.

After a brief retirement, I was fortunate enough to find another role to play in the same capacity but more so in the utility industry for both fossil and nuclear power plants. I was actually not surprised to find the same problem; pumps are getting so aged that parts are no longer available. If you give this a little thought you will probably come to the same alarming opinion…..we have a problem that is nationwide and is not industry specific.

The Situation

Just today I visited with a utility company executive who confirmed that this is a problem that is already large and one that will grow AND that thus far there are few initiatives to address the problem. Most people say that when the pump ends its useful life, it will simply be replaced. This ignores the additional and often very considerable capital cost involved in replacing the pump beyond the cost of the pump itself; such as motors, piping, foundations, interruption in service, etc.

The purpose of my comments is to bring light to this problem and to answer a few simple questions:

Who is responsible for addressing the problem? While many will say this is the fault of the OEM and that they should address it, that is simply not correct. The OEM originally sold the pump noting a useful life of 20-25 years. Many pumps are decades older than that. The companies that originally bought the pumps have enjoyed service well beyond the original estimated useful life of the pumps. Our company recently rebuilt a pump that was 82-years old. The owner of that pump should look back on the purchase of that pump as a real bargain. The current owners of these older pumps should accept responsibility for addressing this problem.

Who in a company’s organization is or should be addressing this problem? A simple way to answer this is to eliminate those departments who are not responsible.

Maintenance? Clearly maintenance is not the place to put this problem. They are focused on one thing: keeping all the equipment working today. There typically is no long-term focus in the Maintenance Department.

Reliability? Another group with a clear focus to make things work longer and better and extend the mean-time-between-repairs. This amazing group has worked wonders in recent years to make things work longer, but they are not focused on keeping up with spare parts availability.

Purchasing? While finding sources is part of the solution to this problem, purchasing is busy placing orders and expediting vendors in order to solve today’s problem.

Supply Chain Management? Yes! My opinion is to let this responsibility rest with this group. In other words, there is a broken link in the supply chain. Many years ago, I had the good fortune to work in Materials Management. A key to that function was Inventory Control and the obvious input to that function was “lead time”. The longer the lead time, the bigger the Inventory Control problem. With these old pumps, the lead time is “infinite” since they are no longer available. The Supply Chain folks get my vote for addressing this problem.

Each organization is free to assign this problem where it wishes, but addressing this problem comes down to taking a few key actions.

First, the problem and its significance should be evaluated. A newer plant may not have a problem at all. OEM’s may be capable of fully supporting the pumps now and for years to come. However, the older the plant, the more significant the problem. Refineries are probably in the worst shape with some power plants right behind them. Some of these plants are 75- to 100-years old. Having a pump in operation 50-years is not unusual.

Second, the critical pumps and their age must be identified. No one can address all the pumps in their plant, so narrowing down the problem is a must. While the list may not be long, many times one pump out of service can be a disaster.

Third, you need to answer the question “Does the OEM still support this model pump and, if so, for how much longer will they ensure a supply of spare parts?” While we can hope that they have them all covered, we all know that they don’t. Bring the focus down to the pumps that are critical and that clearly no longer have OEM support.

Fourth, go ahead and make the decision ahead of time (i.e. when this pump goes down, are we going to replace it or must we keep it operating?) If replacement is the way to go, fine. Get the Engineering people going and put in the Capital Plan to support this strategy. If the decision is to keep the pump in operation, below are some tips that might help support this strategy.

Over the past several years, technology advancement in several areas has grown significantly and is being used to address problems such as parts manufacturing. Two amazing areas of technology advancement that are useful in solving this parts problem are:

Reverse Engineering

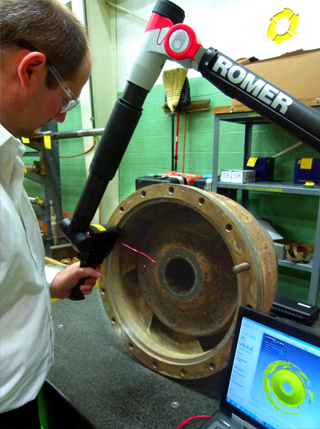

Some people swear by reverse engineering and others swear at it, but it has become an accepted way to maintain the supply of spare parts. OEM’s have even embraced it and most are aggressively developing their own reverse engineering capabilities. Advancements in “user friendly” coordinate measuring machines are simply amazing. Those same machines now offer scanning which is even a more powerful and accurate method of extracting shape information. Add to that the software advancements and reverse engineering is now producing better and better results and doing it faster. Using these processes allows us to develop 3D models of parts which can then be machined or cast.

Photo, courtesy of HydroAire Inc., shows the reverse engineering of a suction bowl

Vane core created via sand printing process

Additive Manufacturing

While most of us are familiar with “subtractive manufacturing” (the process of starting with a piece of metal and removing chips to end up with the shape you desire), “additive manufacturing” essentially starts with nothing and ends up with the shape you desire. While there are many materials that are available using this process, the one that applies to this situation is sand. Using sand, we can now create casting tooling (molds and cores). This allows us to eliminate the time delay involved in making hard tooling for castings. This computer controlled process facilitates making castings faster and better than the traditional process.

Lessons Learned from the Parts Problem

The solution that will work for solving these critical spares issues can best be boiled down to these simple steps. First, identify the parts before you have nothing to work with. Second, look for an opportunity to reverse engineer them. A routine maintenance job is a great time to do this. While the pump is down, identify and reverse engineer the key parts, especially the cast parts. Third, make sure that you or a supplier with which you partner is given and maintains a 3-D model of those parts. With these models stored safely away, someday (perhaps years from now) that model can be recovered and used to make the critical part that keeps your unit operating. In summary, assign the responsibility, develop the targets, develop internal or external reverse engineering capabilities, use those capabilities to develop usable models, store them safely away until needed and become self-sufficient in this critical area.

Avoiding retirement after serving as president of a major reverse engineering and part manufacturing company for 16 years, Jeff Smith recently joined Hydro’s pump service network as president of Hydro Parts Solutions Inc., a new company created to support the pump aftermarket with their parts needs. Having worked for several OEMs in the pump, oilfield and process industries, Jeff is now leading a team to help pump users with difficult-to-source cast parts;, such as impellers, diffusers, discharge heads, casings, bowls and suction bells. For more information about Hydro Parts Solutions, contact Jeff at jsmith@hydroinc.com or call 281-415-8612.

You may also learn more by viewing our video “Introducing Hydro Parts Solutions”.